9-2-2

MEASURING INSULATION RESISTANCE

Refer to

8-4 MEASURING INSULATION RESISTANCE.

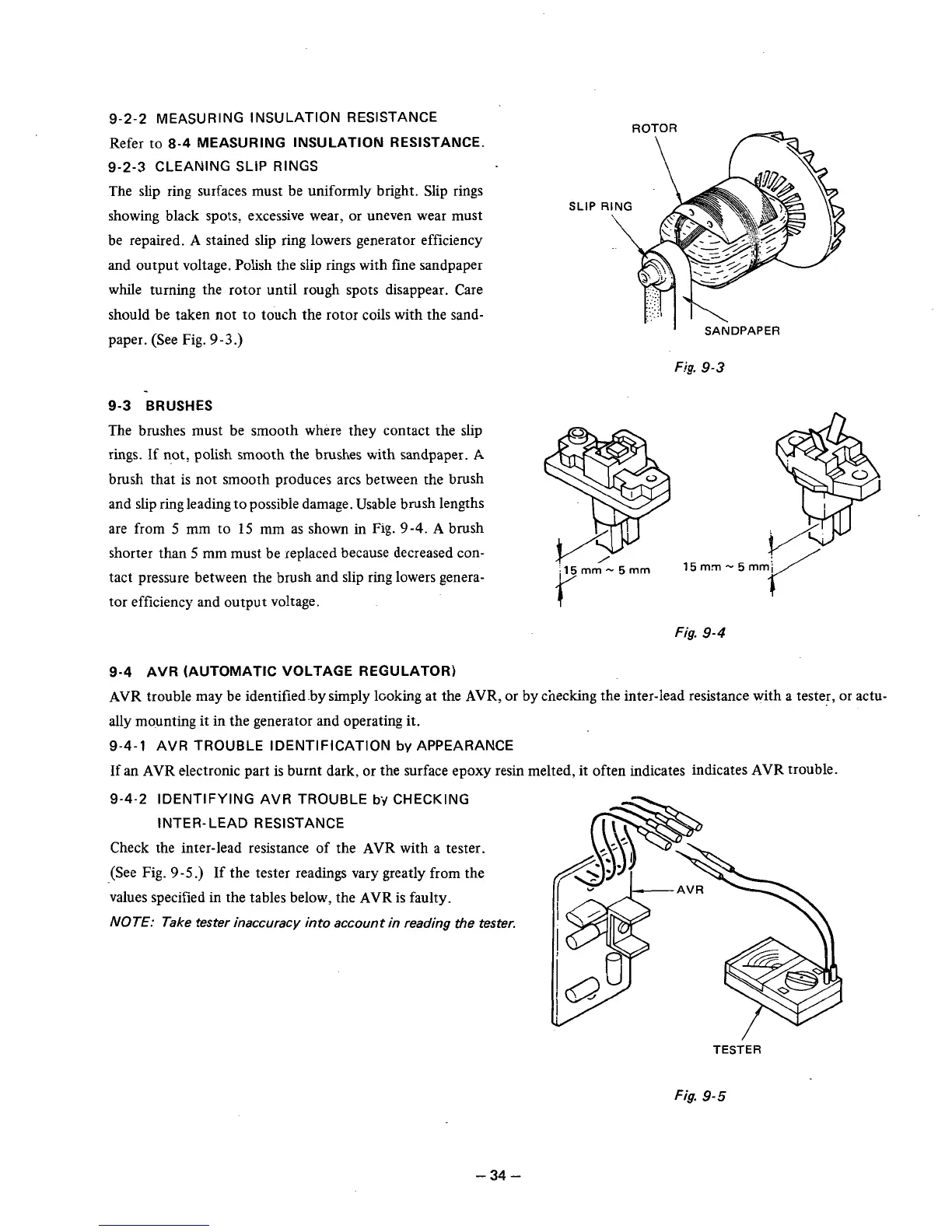

9-2-3

CLEANING SLIP RINGS

The slip ring surfaces must be uniformly bright. Slip rings

showing black spots, excessive wear, or uneven wear must

be repaired.

A

stained slip ring lowers generator efficiency

and output voltage. Polish the slip rings with fine sandpaper

while turning the rotor until rough spots disappear. Care

should be taken not to touch the rotor coils with the sand-

paper. (See Fig.

9

-3

.)

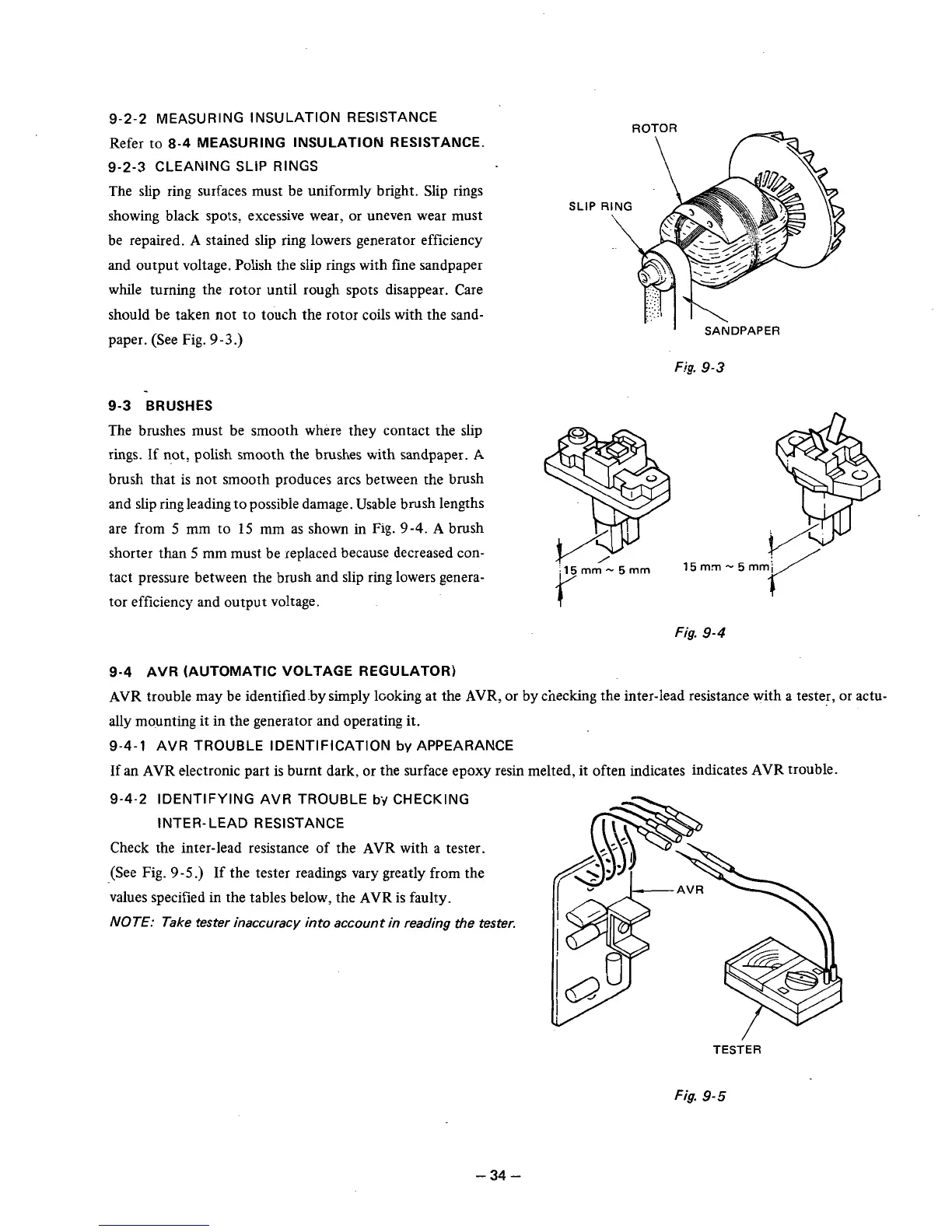

9-3 BRUSHES

The brushes must be smooth where they contact the slip

rings.

If

not, polish smooth the brushes with sandpaper.

A

brush that is not smooth produces arcs between the brush

and slip ring leading to possibie damage. Usable brush lengths

are from

5

mm to

15

mm as shown in Fig.

9-4.

A

brush

shorter than

5

mm must be replaced because decreased con-

tact pressure between the brush and slip ring lowers genera-

tor efficiency and output voltage.

Fig.

9-3

f

i15mm-5mm

15m.m-5m

Fig.

9-4

9-4 AVR (AUTOMATIC VOLTAGE REGULATOR)

AVR

trouble may be identified.by simply koking at the

AVR,

or by checking the inter-lead resistance with a tester, or actu-

ally mounting it in the generator and operating it.

9-4-1

AVR TROUBLE IDENTIFICATION

by

APPEARANCE

If

an

AVR

electronic part is burnt dark,

or

the surface epoxy resin melted, it often indicates indicates

AVR

trouble.

9-4-2

IDENTIFYING AVR TROUBLE

bf

CHECKING

INTER-LEAD RESISTANCE

Check the inter-lead resistance

of

the

AVR

with a tester.

(See Fig.

9-5.)

If the tester readings vary greatly from the

values specified in the tables below, the

AVR

is faulty.

NOTE:

Take tester inaccuracy into account in reading the tester.

TESTER

Fig.

9-5

-34-

Loading...

Loading...