Rockwell Automation Publication 2080-UM002N-EN-E - November 2022 375

Appendix H User-defined Function Block Motion Instructions

The PT Mode is a pulse-pulse follower relationship. When the variable ratio is used and the

ratio is changed, there is no positioning ability. Therefore, when you are finished using the MAG

UDFB, your position scaling (which also uses the E-gear ratio) might have changed if you used

variable Cfg_GearingMode and changed the Master ratio because of your application

requirements.

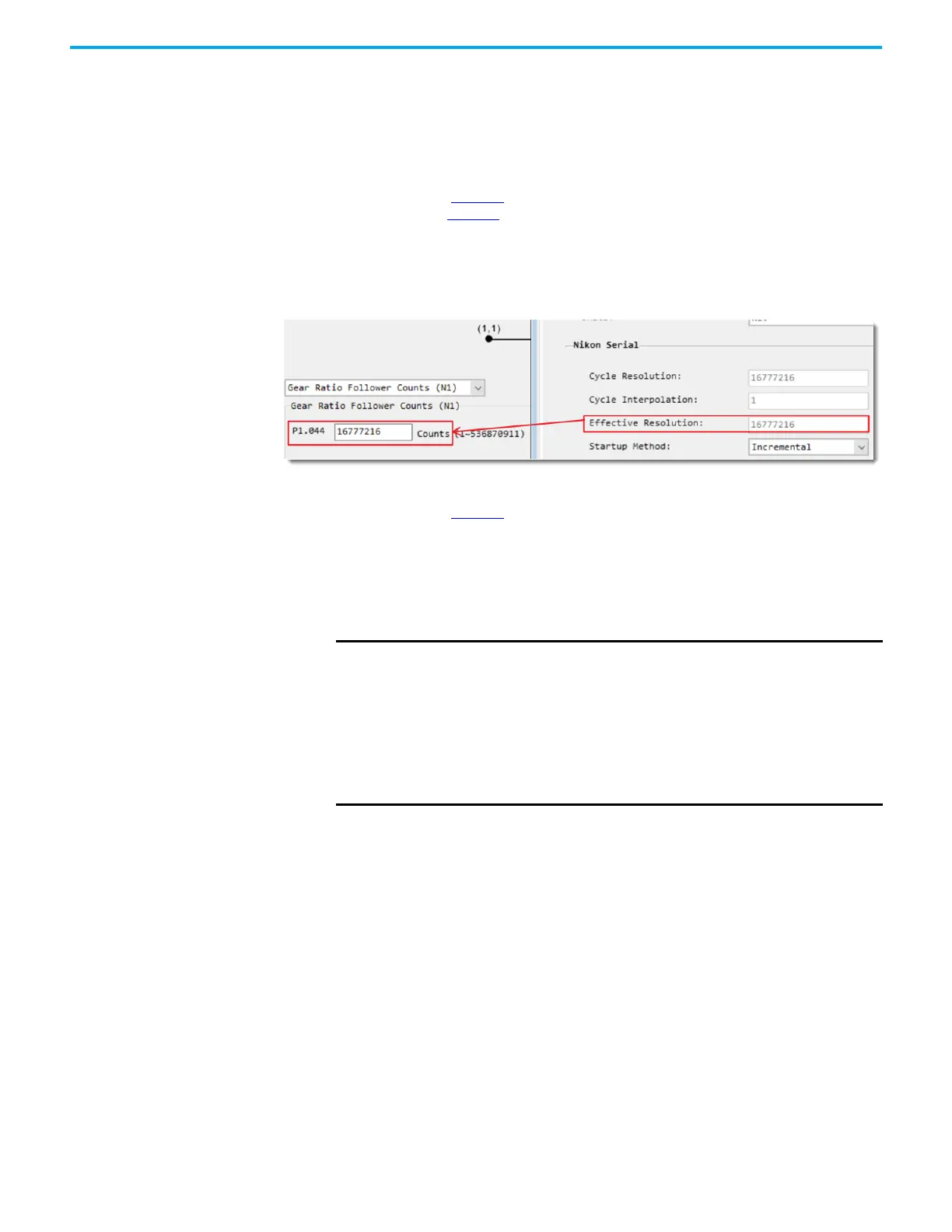

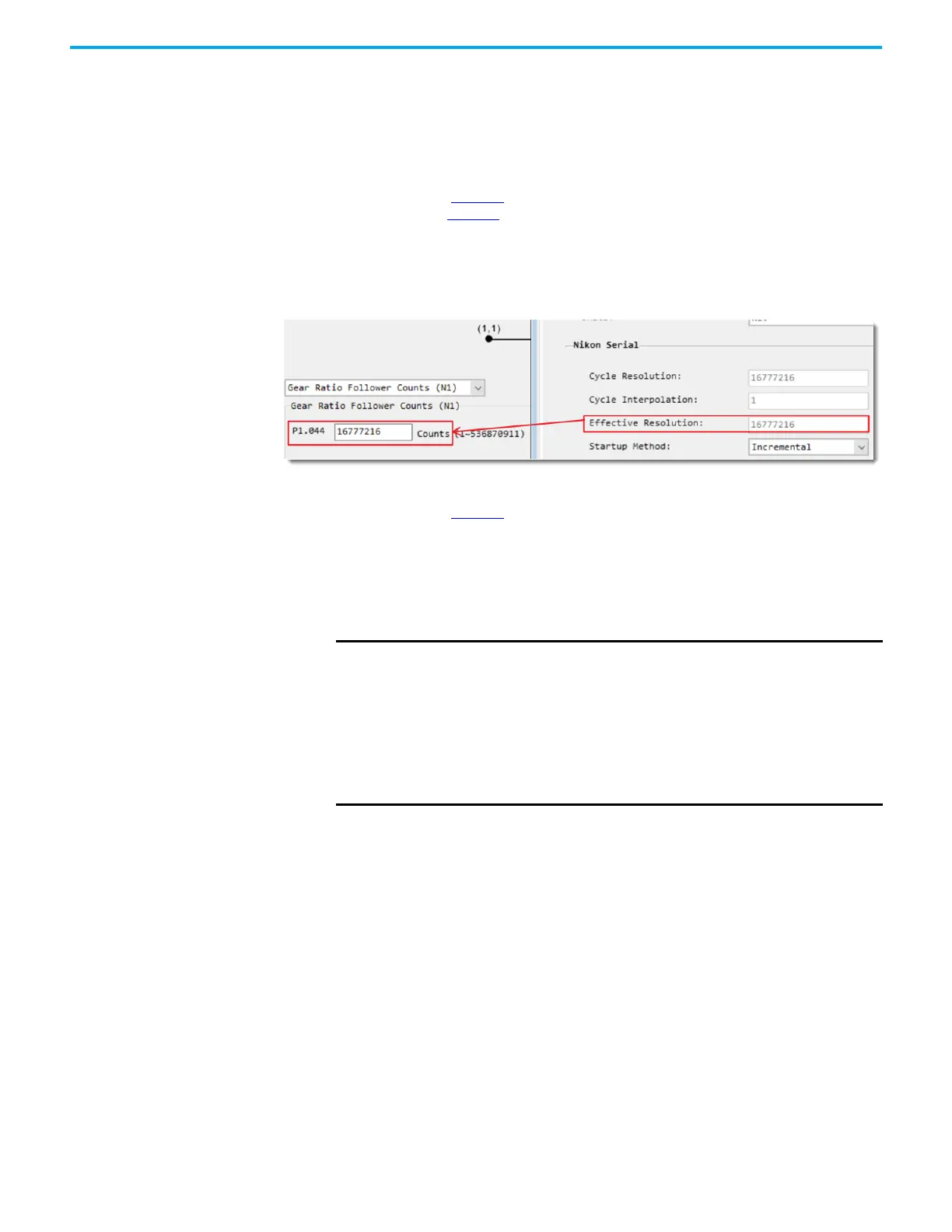

The MAG Set_SlaveCounts is sometimes called the Gear Ratio Follower Counts or numerator

(shown as item 2 in Figure 47

) because it is used to determine the internal 'ratio' of the drive

(shown as 167.77 in Figure 47

).

For our purposes, the E-gear ratio Follower = MAG Set_SlaveCounts = motor feedback

resolution (from the KNX5100C -> Function List -> Motor Selection -> Feedback dialog box).

Figure 48 - Set the Follower Counts

The MAG Set_MasterCounts is sometimes called the Gear ratio Master counts or denominator

(shown as item 3 in Figure 47). Any gearing relationship must consider the actual motor

mechanics, like a gearbox, or actuator pitch, and use those mechanics to relate back to a

motor rotation. Gear Ratio Master counts is desired counts/motor rotation. Desired counts are

not used for positioning; but defines how many counts your motor moves in one rotation

based on the number of feedback pulses you expect to receive from the source input, which is

used to determine your gearing relationship. So, this Master counts value is used to define the

pulse-pulse relationship.

Gearing example

The master in our system is a 4000 ppr encoder. When the encoder makes one revolution, we

expect the Slave1 drive to see: 4000 pulses.

Our application requirement is that we want to follow this encoder at a 1:2 relationship. So,

when the master encoder moves one encoder revolution, the motor rotates two times.

The Master PPR is not entered anywhere, but is required that we know this value. We calculate

the MAG Set_MasterCounts value knowing the Master PPR counts and the relationship we want

in the Slave1 motor.

We set the MAG Set_SlaveCounts = Motor Feedback Resolution = 16,777,216.

We set MAG Set_MasterCounts = 2000, so when the Slave1 drive sees 2000 master pulses, the

Slave1 motor moves one rotation, and thus, as the Master encoder moves 4000 pulses, Slave1

would have moved two rotations.

IMPORTANT The MAG can affect your positioning. The issuing Kinetix 5100 drive

(slave) uses the E-gear ratio to define how it follows pulses from a

source (a master). While the result is that the issuing Kinetix 5100 drive

(slave) follows pulses from another source master, the way the function

operates can affect positioning of the drive. Regardless of Operation

Mode, the E-gear ratio is always used to provide a representation of

positioning (units or counts) or to define a Pulse-Pulse Following

relationship (MAG/PT). When the E-gear ratio is changed, the positioning

of the axis is changed.

Loading...

Loading...