376 Rockwell Automation Publication 2080-UM002N-EN-E - November 2022

Appendix H User-defined Function Block Motion Instructions

There are two modes of the MAG function that can be used. These modes are defined by the

Cfg_GearingMode entry. This entry is set for Fixed initially. You must intentionally change this

setting. Fixed mode does not impact positioning because it uses the existing E-gear ratio in

the Kinetix 5100 drive. Therefore, we can follow a master source at this fixed ratio and when

gearing is disabled, we can continue positioning without losing the position scaling for the

drive.

Variable mode lets you change the E-gear ratio by manipulating the master/slave counts

values. The variable mode lets you change the ratio. When the ratio is changed, the motor

positioning is affected because the E-gear ratio is also used to define Position Scaling. If you

require positioning after using the variable gearing, issue a Homing Sequence to re-establish

an origin.

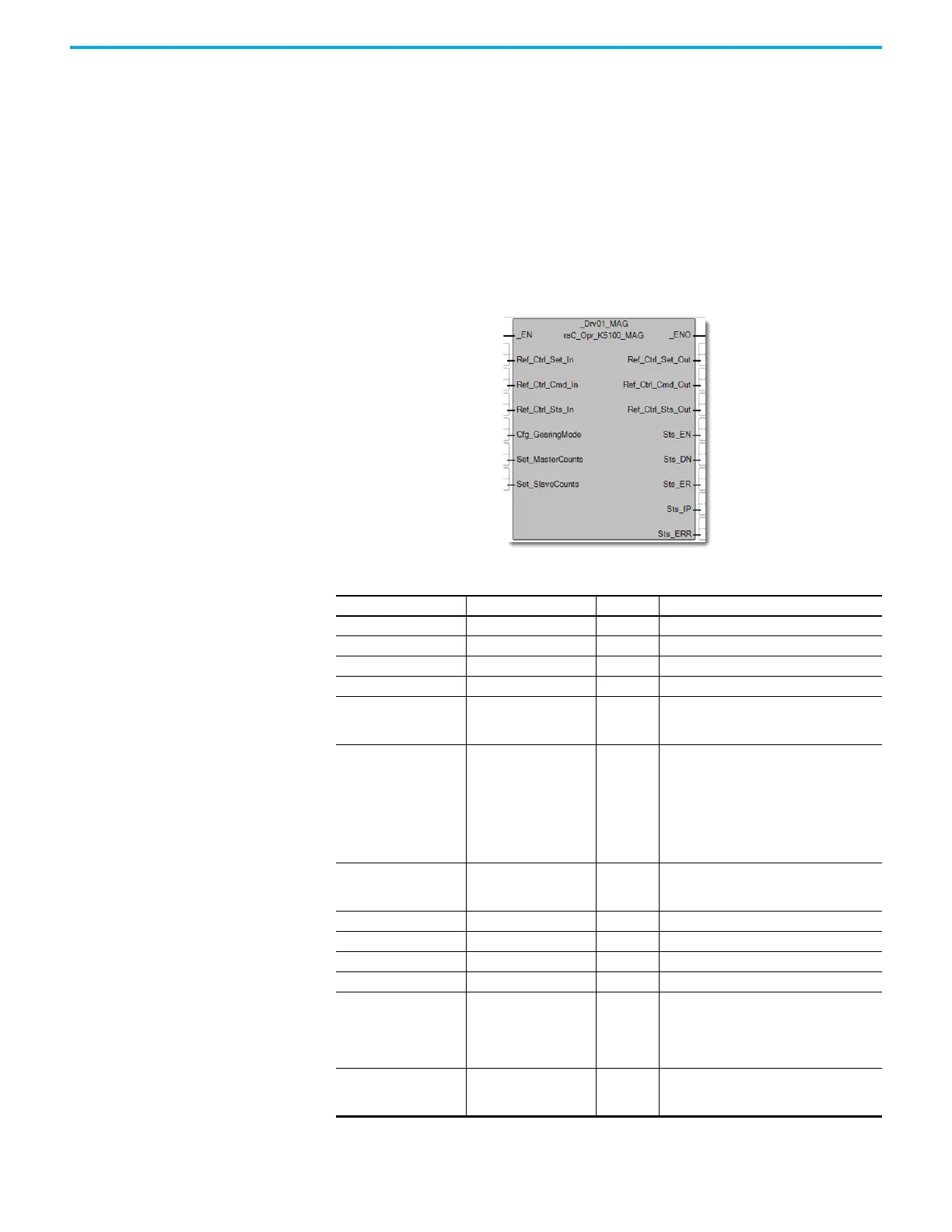

Figure 49 - MAG Diagram

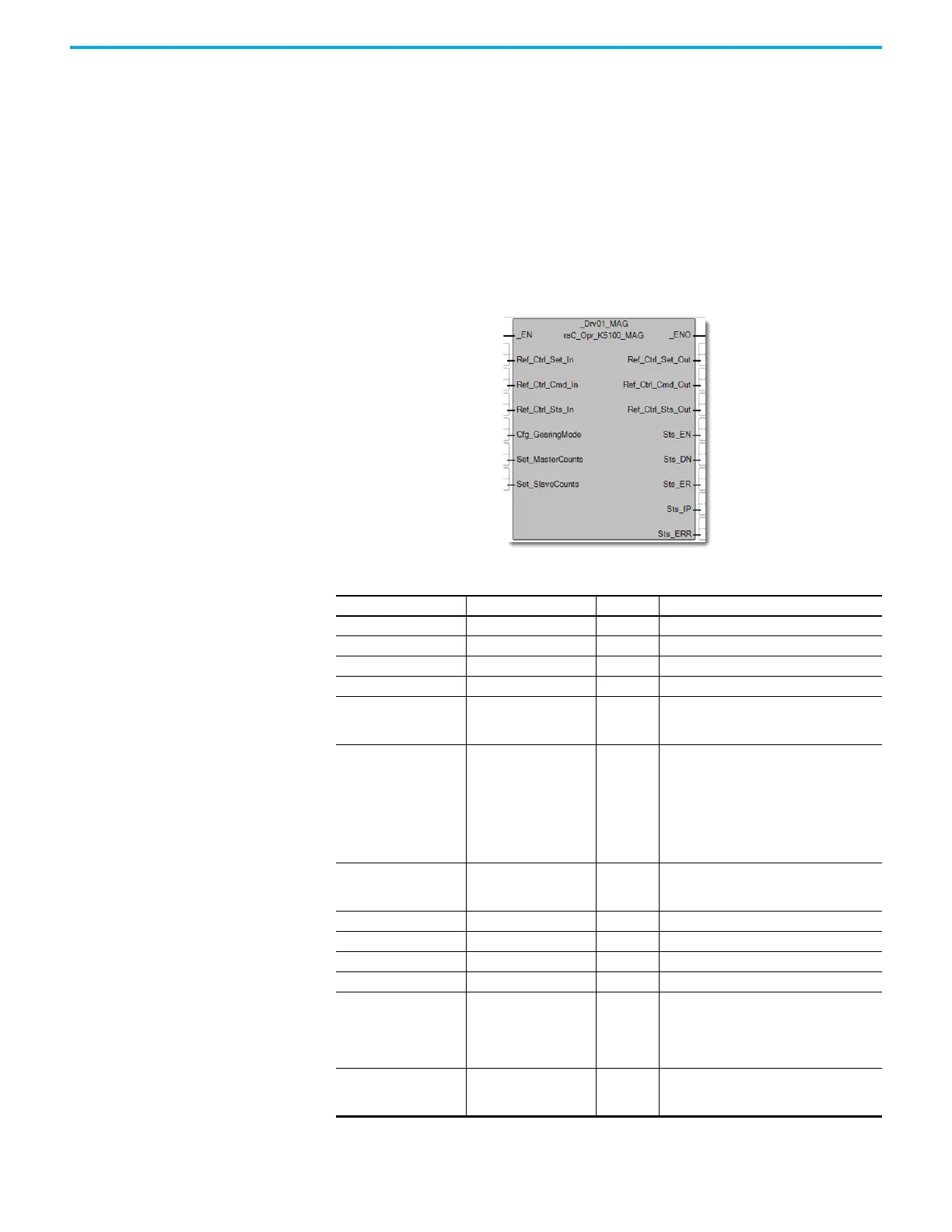

Table 115 - MAG Operands

Operand Type Format Description

_EN BOOL Tag True when the rung is enabled.

Ref_Ctrl_Set_In raC_UDT_Itf_K5100_Set Tag Interface from device object.

Ref_Ctrl_Cmd_In raC_UDT_Itf_K5100_Cmd Tag Interface from device object.

Ref_Ctrl_Sts_In raC_UDT_Itf_K5100_Sts Tag Interface from device object.

Cfg_GearingMode BOOL

Immediate

value or

Tag

0 = Fixed

1 = Variable

Set_MasterCounts DINT

Immediate

value or

Tag

Sets the value of E-gear ratio: Denominator

ID152 (P1.045). Set this value to represent the

desired counts/motor rotation. This value

defines the number of pulses/motor rotation

and when used with the feedback pulses you

expect to see from the source input (also

pulses/ revolution) provides a gearing

relationship.

Set_SlaveCounts DINT

Immediate

value or

Tag

Sets the value of E-gear ratio: Numerator

ID151 (P1.044). Set this value the same as the

Motor Feedback Resolution.

_ENO BOOL Tag True when this UDFB output is enabled.

Ref_Ctrl_Set_Out raC_UDT_Itf_K5100_Set Tag Interface to device object.

Ref_Ctrl_Cmd_Out raC_UDT_Itf_K5100_Cmd Tag Interface to device object.

Ref_Ctrl_Sts_Out raC_UDT_Itf_K5100_Sts Tag Interface to device object.

Sts_EN (Enable) BOOL Tag

This bit is set when the rung makes a false-

to-true transition and the message

transaction to MAG is initiated and in process.

It remains high until the rung-in condition is

false and no faults are active.

Sts_DN (Done) BOOL Tag

This bit is set when the rung makes a false-

to-true transition and the message

transaction to MAG (Sts_EN) is complete.

Loading...

Loading...