Rockwell Automation Publication PFLEX-AP005A-EN-P - October 2010 39

Drive Selection Considerations Chapter 1

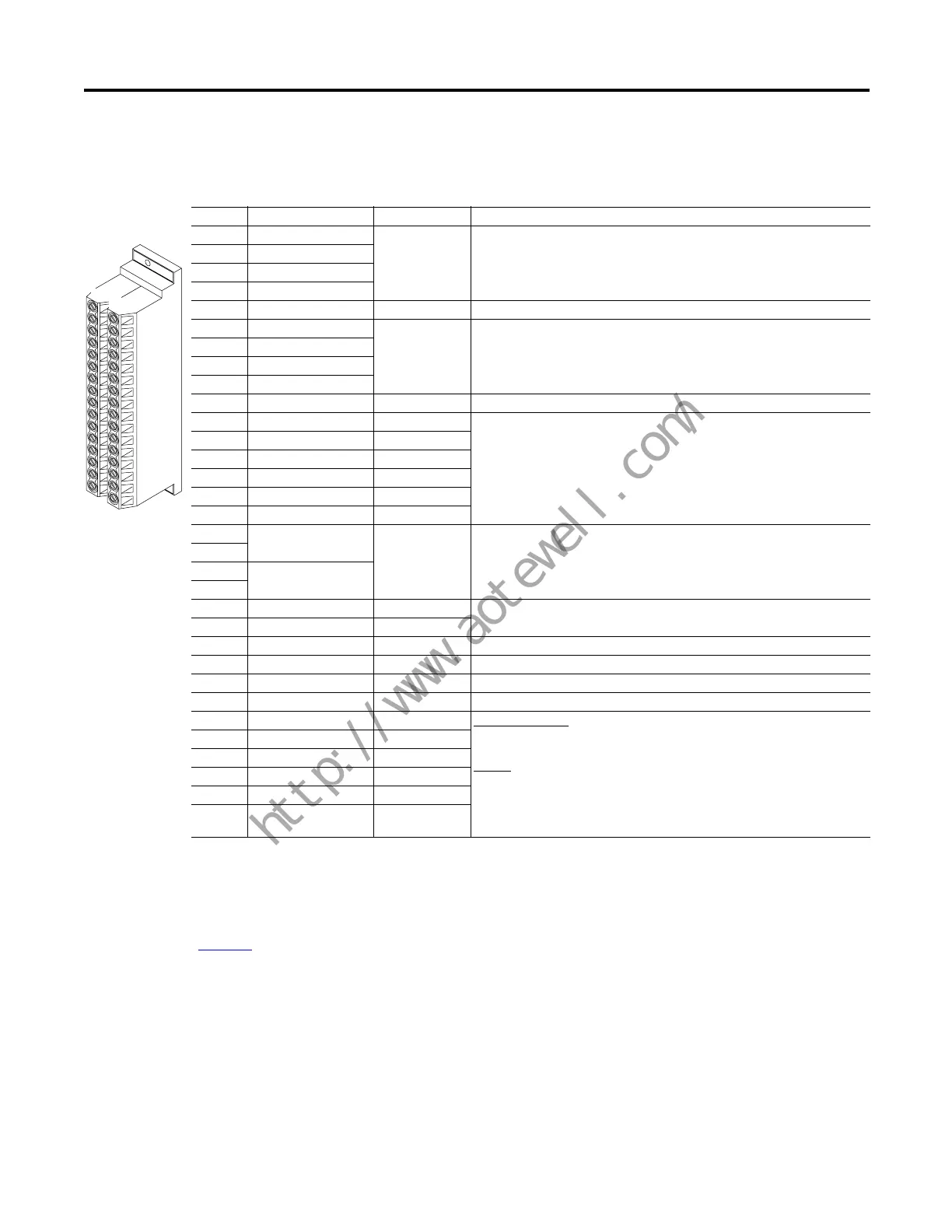

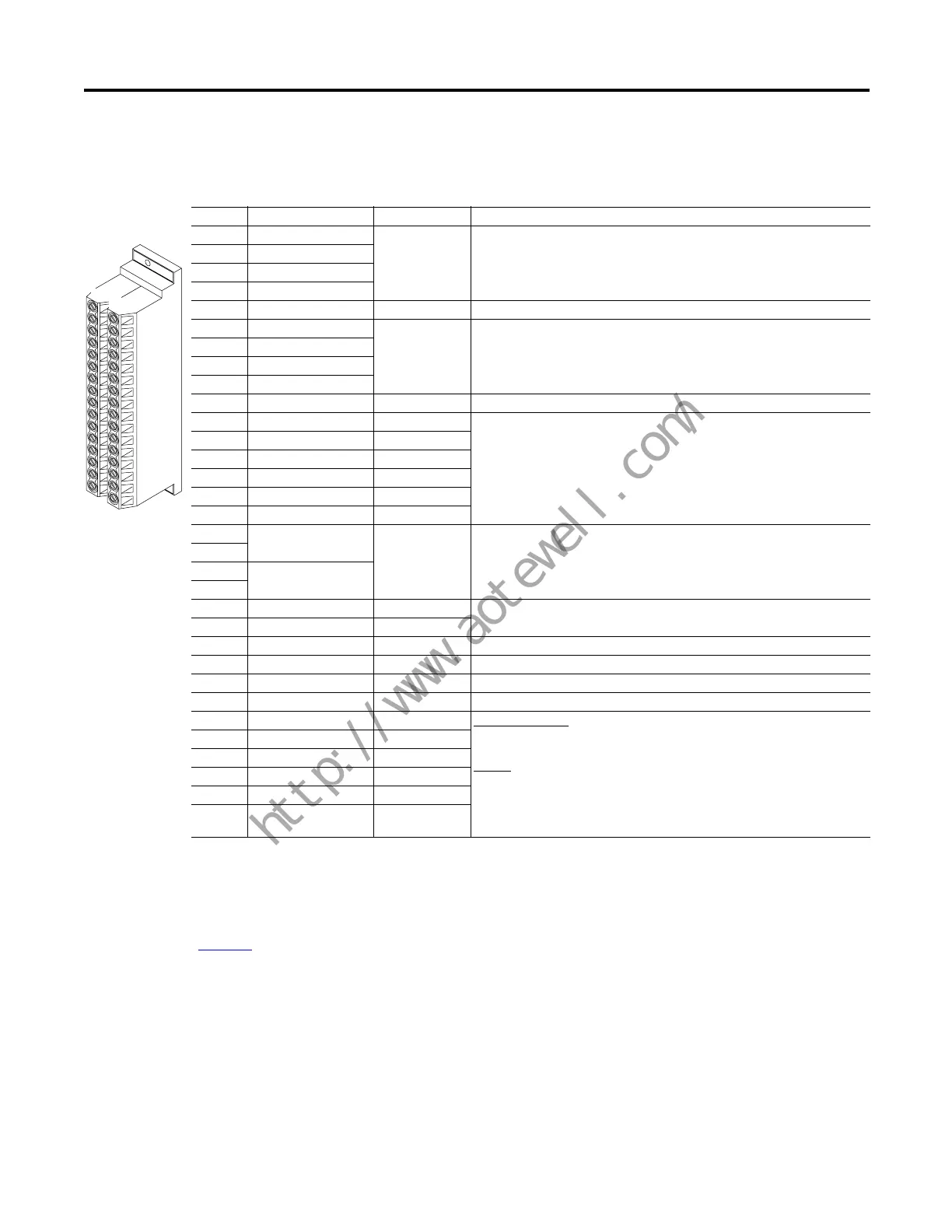

PowerFlex 700 Drives I/O Cassette Terminals

Table 15 - PowerFlex 700 Drives I/O Control Terminal Designations (Frames 0…6)

Terminal Name Factory Default Description

1 Analog In 1 (–)

(1) (4)

Isolated

(5)

, bipolar, differential, ±10V/0-20 mA, 11 bit & sign

For 0-20 mA, a jumper must be installed at terminals 17 & 18 (or 19 & 20)

88 k ohm input impedance when configured for volt & 95.3 ohm for current

2 Analog In 1 (+)

(1)

3 Analog In 2 (–)

(1)

4 Analog In 2 (+)

(1)

5 Pot Common – For (+) and (–) 10V pot references

6 Analog Out 1 (–)

(4)

Single-ended bipolar (current output is not bipolar), ±10V/0-20mA, 11 bit &

sign, Voltage mode - limit current to 5 mA. Current mode - max. load is 400

ohms

7 Analog Out 1 (+)

8 Analog Out 2 (–)

9 Analog Out 2 (+)

10 HW PTC Input 1 – 1.8k ohm PTC, Internal 3.32k ohm pull-up resistor

11 Digital Out 1 – N.C.

(2)

Fault Max. Resistive Load:

240V AC/30V DC – 1200VA, 150W

Max. Current: 5A, Min. Load: 10 mA

Max. Inductive Load:

240V AC/30V DC – 840VA, 105W

Max. Current: 3.5A, Min. Load: 10 mA

12 Digital Out 1 Common

13 Digital Out 1 – N.O.

(2)

NOT Fault

14 Digital Out 2 – N.C.

(2)

NOT Run

15 Digital Out 2/3 Com.

16 Digital Out 3 – N.O.

(2)

Run

17 Current In Jumper

(1)

–

Analog In 1

Placing a jumper across terminals 17 & 18 (or 19 & 20) will configure that

analog input for current

18

19 Current In Jumper

(1)

–

Analog In 2

20

21 –10V Pot Reference – 2k ohm minimum load

22 +10V Pot Reference –

23 HW PTC Input 2 – See above

24 +24V DC

(6)

– Drive supplied logic input power

(6)

25 Digital In Common –

26 24V Common

(6)

– Common for internal power supply

27 Digital In 1

(3)

Stop - CF 115V AC, 50/60 Hz - Opto isolated

Low State: less than 30V AC

High State: greater than 100V AC, 5.7 mA

24V DC

- Opto isolated

Low State: less than 5V DC

High State: greater than 20V DC, 10 mA DC Digital Input Impedance: 21k ohm

28 Digital In 2

(3)

Start

29 Digital In 3

(3)

Auto/Man.

30 Digital In 4

(3)

Speed Sel 1

31 Digital In 5

(3)

Speed Sel 2

32 Digital In 6/Hardware

Enable

(3)

Speed Sel 3

(1) Important: 0-20 mA operation requires a jumper at terminals 17 & 18 (or 19 & 20). Drive damage may occur if jumper is not installed.

(2) Contacts in unpowered state. Any relay programmed as Fault or Alarm will energize (pick up) when power is applied to drive and deenergize (drop out) when a fault or

alarm exists. Relays selected for other functions will energize only when that condition exists and will deenergize when condition is removed.

(3) A 10 k Ohm, 2 W burden resistor must be installed on each digital input when using a triac-type device. The resistor is installed between each digital input and neutral/

common.

(4) These inputs/outputs are dependant on a number of parameters. For more information, see Chapter 3, Programming and Parameters, in the PowerFlex 700 AC Drives User

Manual, publication 20B-UM002

.

(5) Differential Isolation - External source must be maintained at less than 160V with respect to PE. Input provides high common mode immunity.

(6) 150 mA maximum Load. Not present on 115V versions.

16

32

1

17

Loading...

Loading...