Do you have a question about the Rosemount 3051SMV and is the answer not in the manual?

Mounting instructions for liquid flow applications.

Mounting instructions for gas flow applications.

Mounting instructions for steam flow applications.

Details on panel and pipe mounting brackets for the transmitter.

Guidelines for transmitter assembly and bolt selection for a tight seal.

Adjusting the transmitter housing for improved access or display viewing.

Setting alarm and security switches on the transmitter.

Procedures for connecting wiring and powering the transmitter.

Visual guides illustrating transmitter wiring connections.

DC power supply specifications and loop load limitations.

Installing a Pt 100 RTD sensor for process temperature input.

Overview of PC-based software for transmitter configuration.

Minimum system requirements for installing the Engineering Assistant software.

Procedure for connecting a PC to the transmitter for configuration.

Guidance on creating flow configurations using the software.

Explanation of the software's navigation interface and tabs.

Selecting preferred engineering units and flow parameters.

Choosing the process fluid from the software database.

Verifying fluid density, compressibility, and viscosity.

Selecting and configuring the primary flow element.

Saving and sending the transmitter configuration data.

Fast key sequences for verifying device configuration parameters.

Adjusting the transmitter zero point for pressure sensors.

List of authorized manufacturing sites for the product.

FM certification for ordinary location use.

Compliance with European directives including ATEX.

North American certifications for hazardous locations.

CSA hazardous location approval details.

ATEX intrinsic safety and type n certifications.

Declaration of conformity for the EMC Directive.

Declaration of conformity for the PED Directive.

Declaration of conformity for the ATEX Directive.

Details of notified bodies involved in conformity assessment.

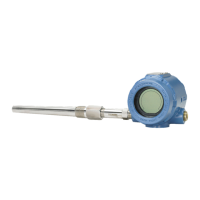

| Type | Multivariable Transmitter |

|---|---|

| Measurement Parameters | Differential Pressure, Static Pressure, Temperature |

| Communication Protocols | HART, FOUNDATION Fieldbus, PROFIBUS PA |

| Ambient Temperature Range | -40 to 85 °C (-40 to 185 °F) |

| Output | 4-20 mA HART |

| Pressure Range | Up to 2000 psi (137, 9 bar) |

| Material | 316L SST |

| Service | Liquid, Gas, Steam |

| Turn Down | 100:1 |

| Process Connection | 1/2 – 14 NPT |

| Diagnostics | Basic Diagnostics |

| Certifications/Approvals | ATEX, IECEx, FM, CSA |

| Enclosure Rating | NEMA 4X, IP66 |

| Electrical Connection | 1/2 – 14 NPT, M20 x 1.5 |

| Accuracy | ±0.04% of Span (typical) |

Loading...

Loading...