6

• Always keep bolts tight. Check periodically.

• Always raise lift when cleaning floor area with solvents and/

or cleaning compounds.

• Always keep lift components clean.

• Always, if fluid leakage is observed, call local service repre-

sentative.

• Daily: Check cables and sheaves for wear. If parts are dam-

aged or worn, call local service representative to replace.

• Daily: Inspect front wheel stops and ramp/chocks for dam-

age or excessive wear. If parts are damaged or worn, call

local service representative to replace.

OPERATOR INSPECTION & MAINTENANCE

(MAINTENANCE AUTHORIZED BY OPERATOR)

•Daily:Check locking latch operation and reset. If not operat-

ing properly, call local service representative.

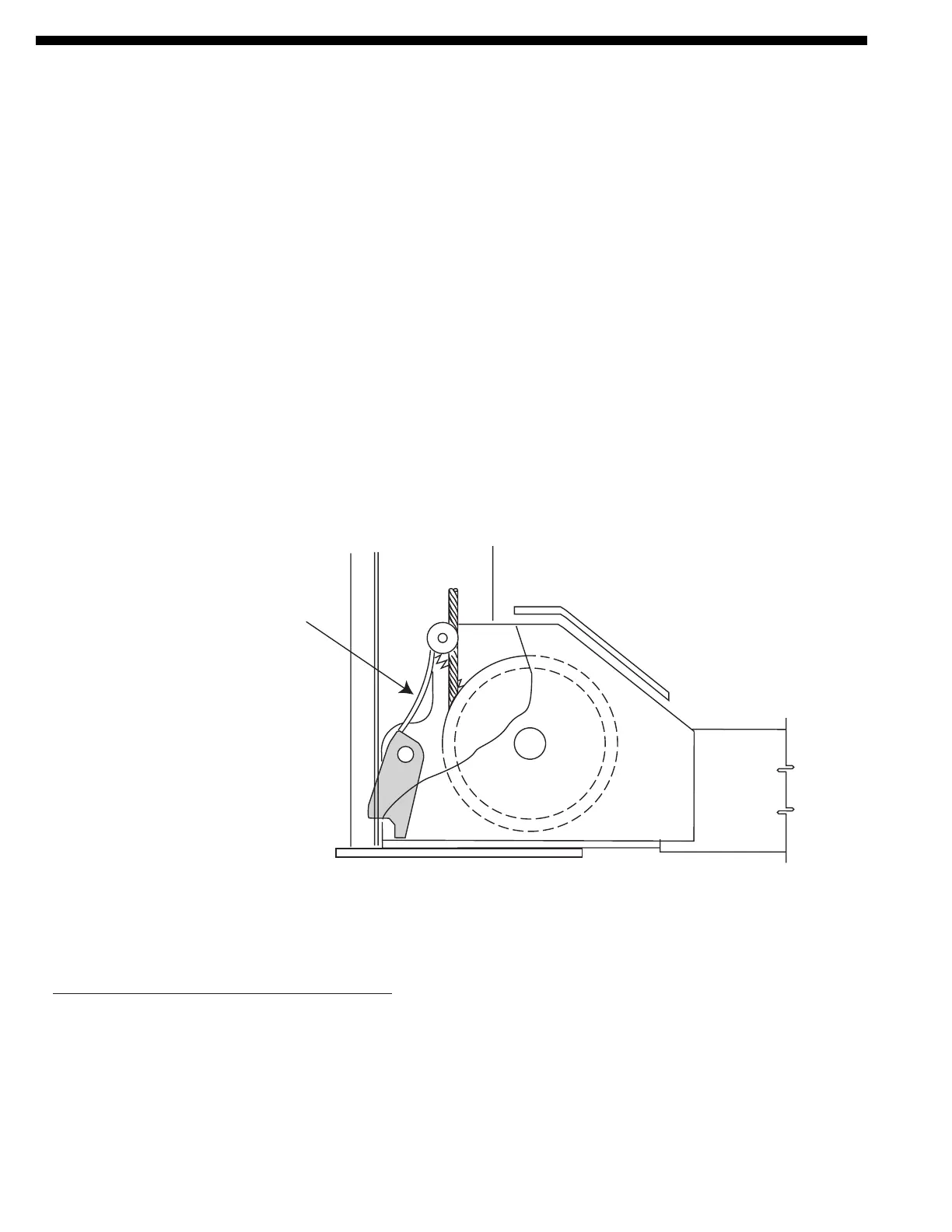

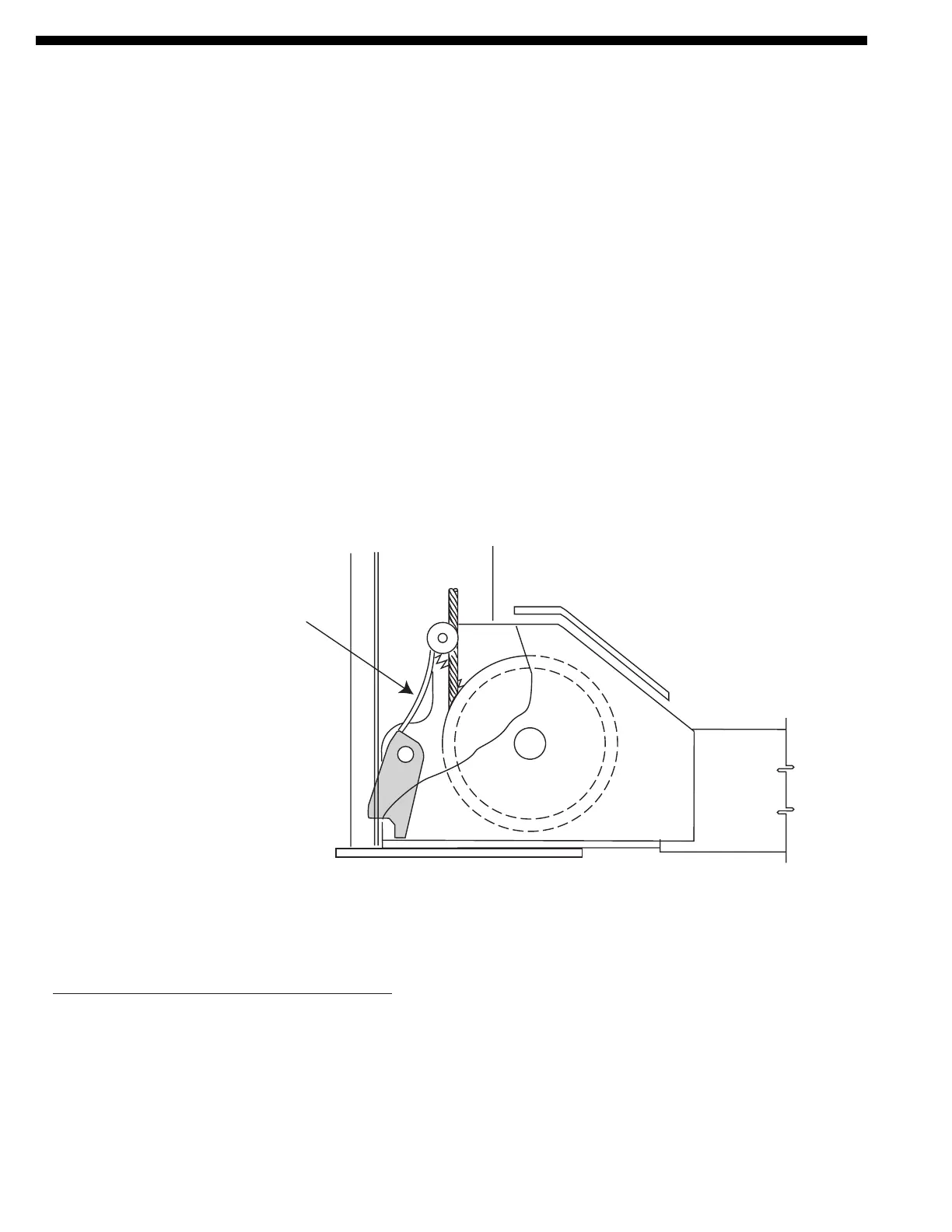

• Daily: Check for permanent deformation of slack cable arms

(see below). If present, call local service representative to

replace parts.

• Monthly: Check slack cable switches for function.

• Every3Months: Check anchor bolts for tightness. Anchors

should be torqued to 61 N - m.

• Every6months: Check fluid level of lift power unit and refill

to proper level in level indicator with lift fully lowered.

• Replace all decals on the lift if unable to read or missing.

Reorder labels from Rotary Lift.

Replace if bent

NOTE: LIFT SHOULD RAISE LEVEL. IF LIFT IS NOT RAISING LEVEL, CHECK

CABLES FOR STRETCH. CABLES MAY NEED ADJUSTMENT

(BY AUTHORIZED PERSONNEL). MOST CABLE STRETCH OCCURS DURING

THE FIRST 30 - 90 DAYS OF LIFT USE.

Loading...

Loading...