d03933

page 9 - 3

Jan. 01/2007

Effectivity: 912 Serie

OM Edition 1 / Rev. 0

BRP-Rotax

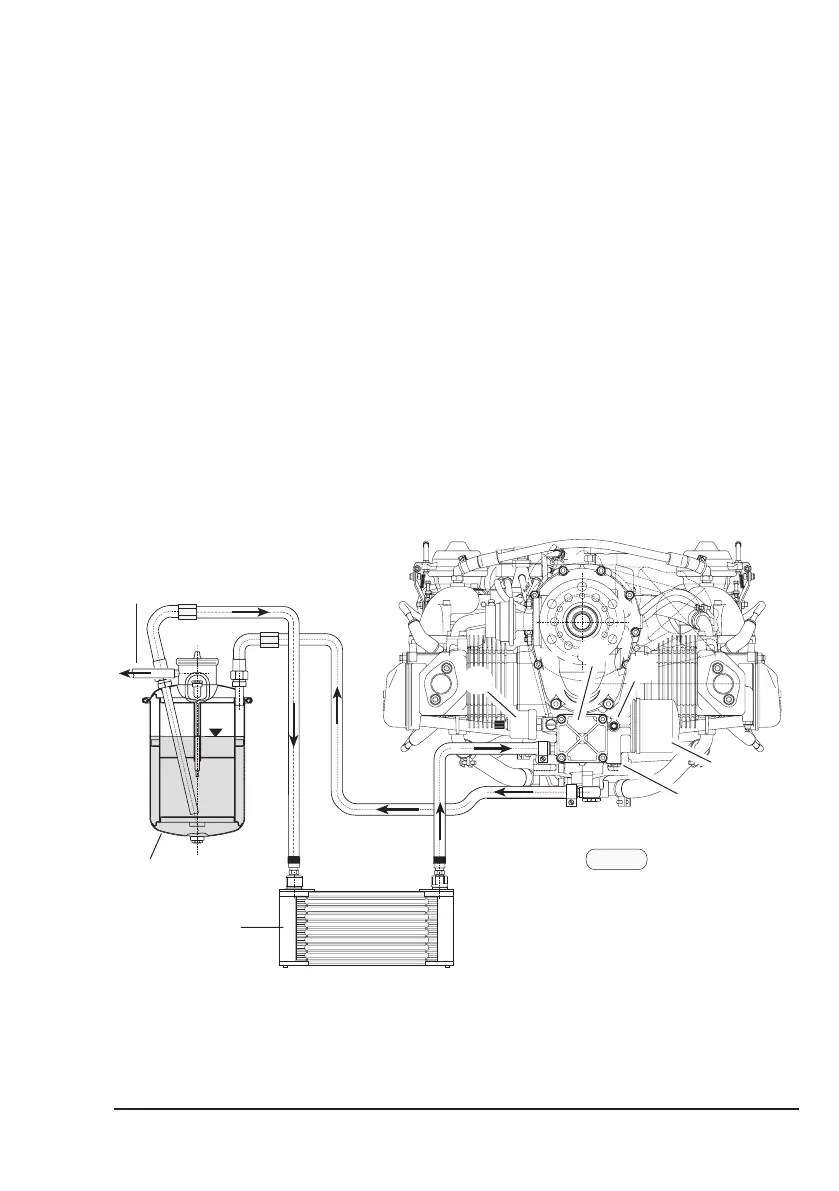

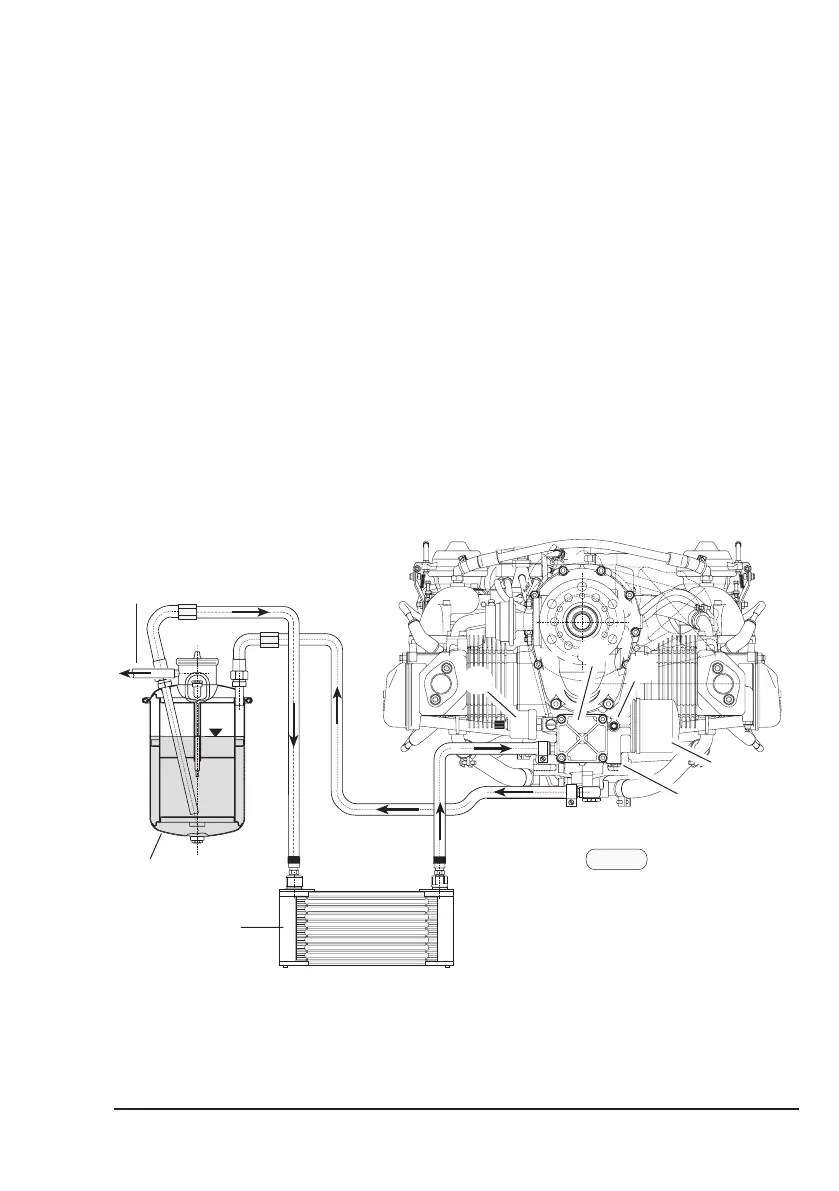

9.3) Lubrication system

See fig. 6.

The ROTAX 912 engine is provided with a dry sump forced lubrication

system with a main oil pump with integrated pressure regulator (1) and oil

pressure sensor (2).

◆ NOTE: The oil pump is driven by the camshaft.

The oil pump (3) sucks the motor oil from the oil tank (4) via the oil cooler (5)

and forces it through the oil filter (6) to the points of lubrication in the engine.

The surplus oil emerging from the points of lubrication accumulates on the

bottom of crankcase and is forced back to the oil tank by the blow-by gases.

◆ NOTE: The oil circuit is vented via bore (7) on the oil tank.

◆ NOTE: The oil temperature sensor (8) for reading of the oil inlet

temperature is located on the oil pump housing.

Lubricants, see Chapter 10.2.3).

8

3

2

fig. 6

00523

7

5

4

2

3

8

1

6

Loading...

Loading...