Effectivity: 914 Serie BRP-Powertrain page 8-2

OM Edition 2 / Rev. 0 April 01/2010

d04480.fm

8.1) Engine preservation

General note

Due to the special material of the cylinder wall, there is no need

for extra protection against internal cylinder corrosion for the RO-

TAX aircraft engines. At extreme climatic conditions and for long

out of service periods we recommend the following to protect the

valve guides against corrosion:

8.2) Engine back to operation

If preservation (including oil change) took place within a year of

storage, oil renewal will not be necessary. For longer storage pe-

riods repeat preservation annually.

Risk of burnings and scalds!

Hot engine parts!

Always allow engine to cool down to ambient

temperature before start of any work.

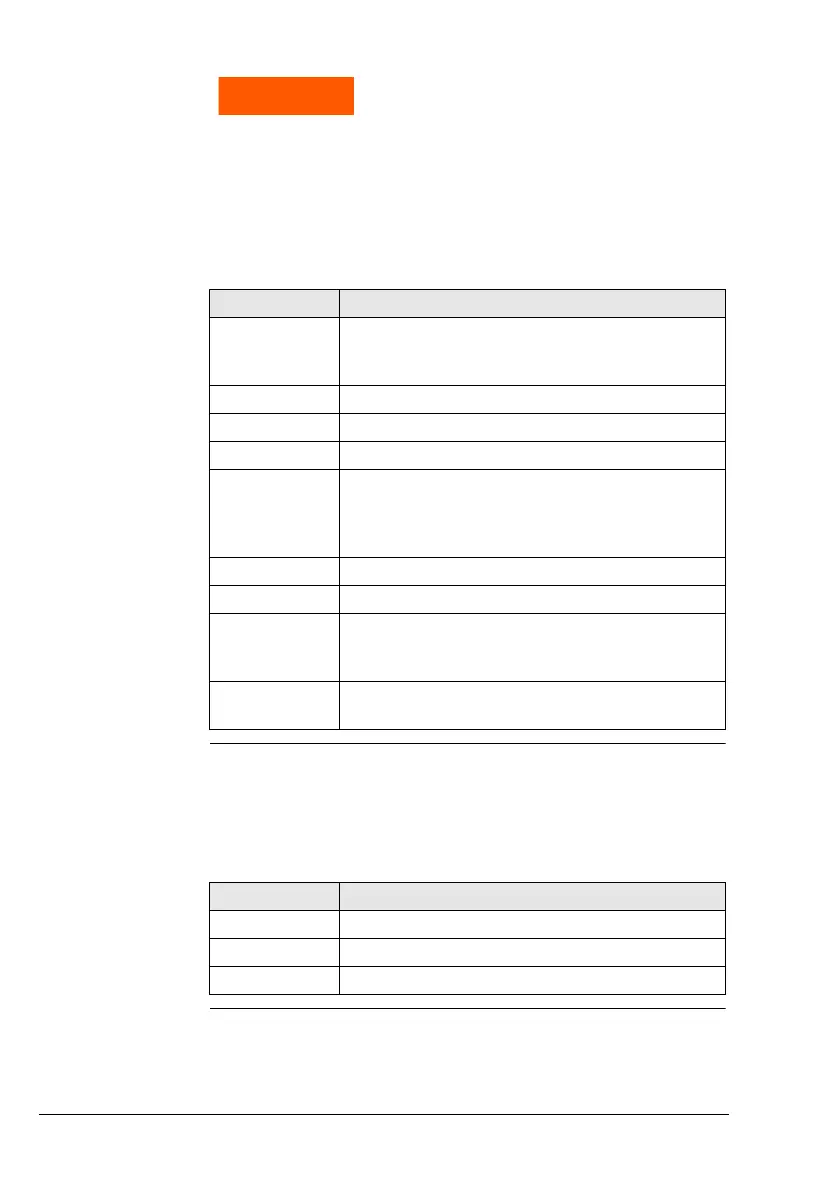

Step Procedure

1 Operate the engine until the temperatures have stabi-

lized for a period of 5 min (engine oil temperature be-

tween 50 to 70 °C (122 to 160 °F).

2 Switch the engine OFF.

3 Allow the engine to cool down.

4 Change oil.

5 Remove the air intake filters and insert approx.

30 cm³ (1 fl oz) of corrosion inhibiting oil into the car-

buretor throat with the engine running at increased

idle speed. Shut off engine.

6 Drain carburetor float chamber.

7 Apply oil to all joints on carburetors.

8Close all openings on the cold engine, such as ex-

haust end pipe, venting tube, air filter etc. against en-

try of dirt and humidity.

9 Spray all steel external engine parts with corrosion in-

hibiting oil.

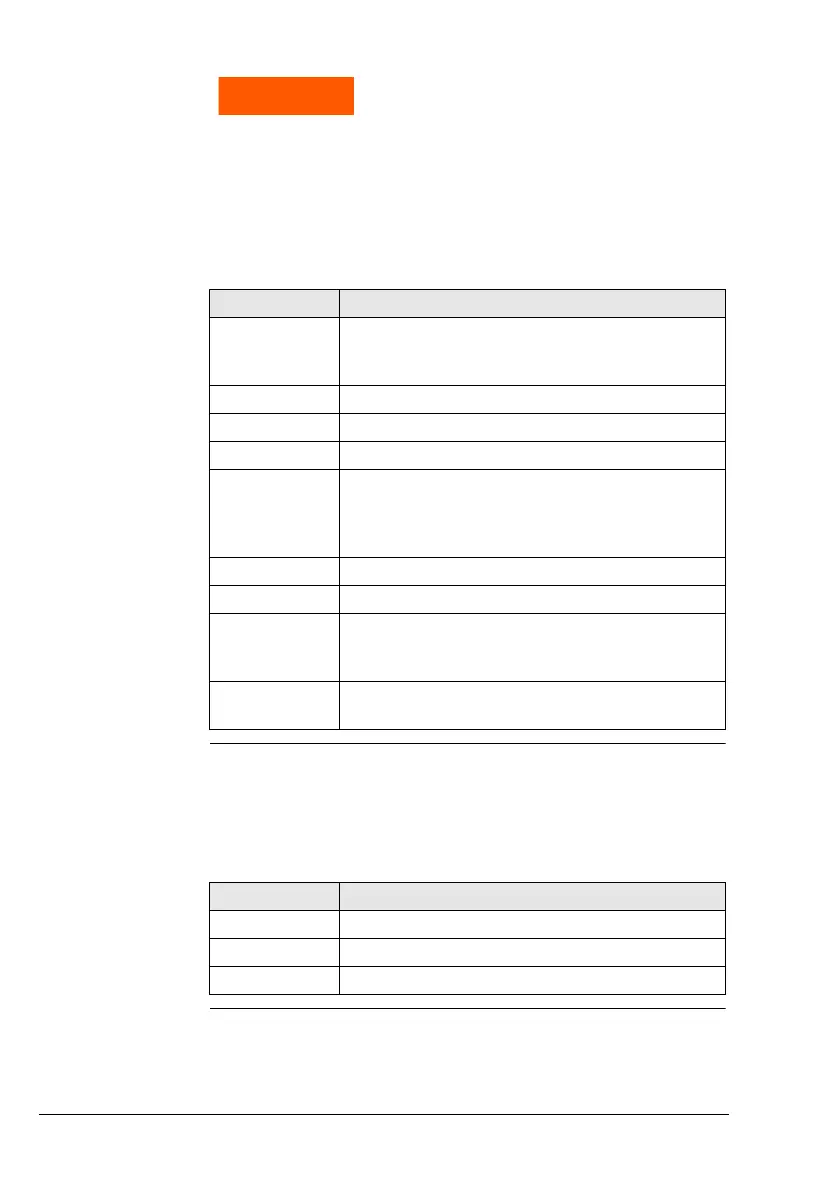

Step Procedure

1 Remove all plugs and caps.

2 Clean spark plugs with plastic brush and solvent .

3 Reinstall.

Loading...

Loading...