9 x Faults and malfunctions

61

FA ROTEX A1 BO - 10/2007

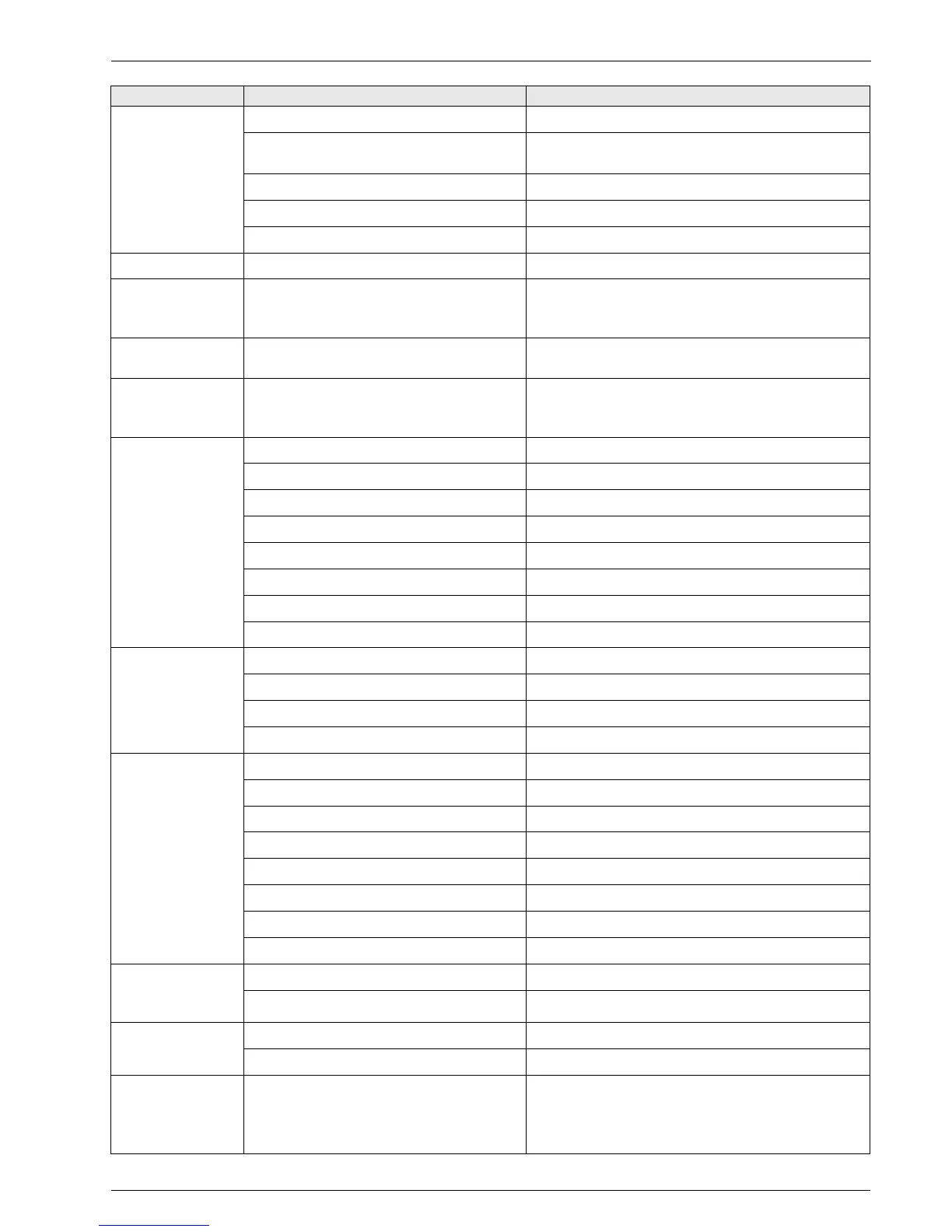

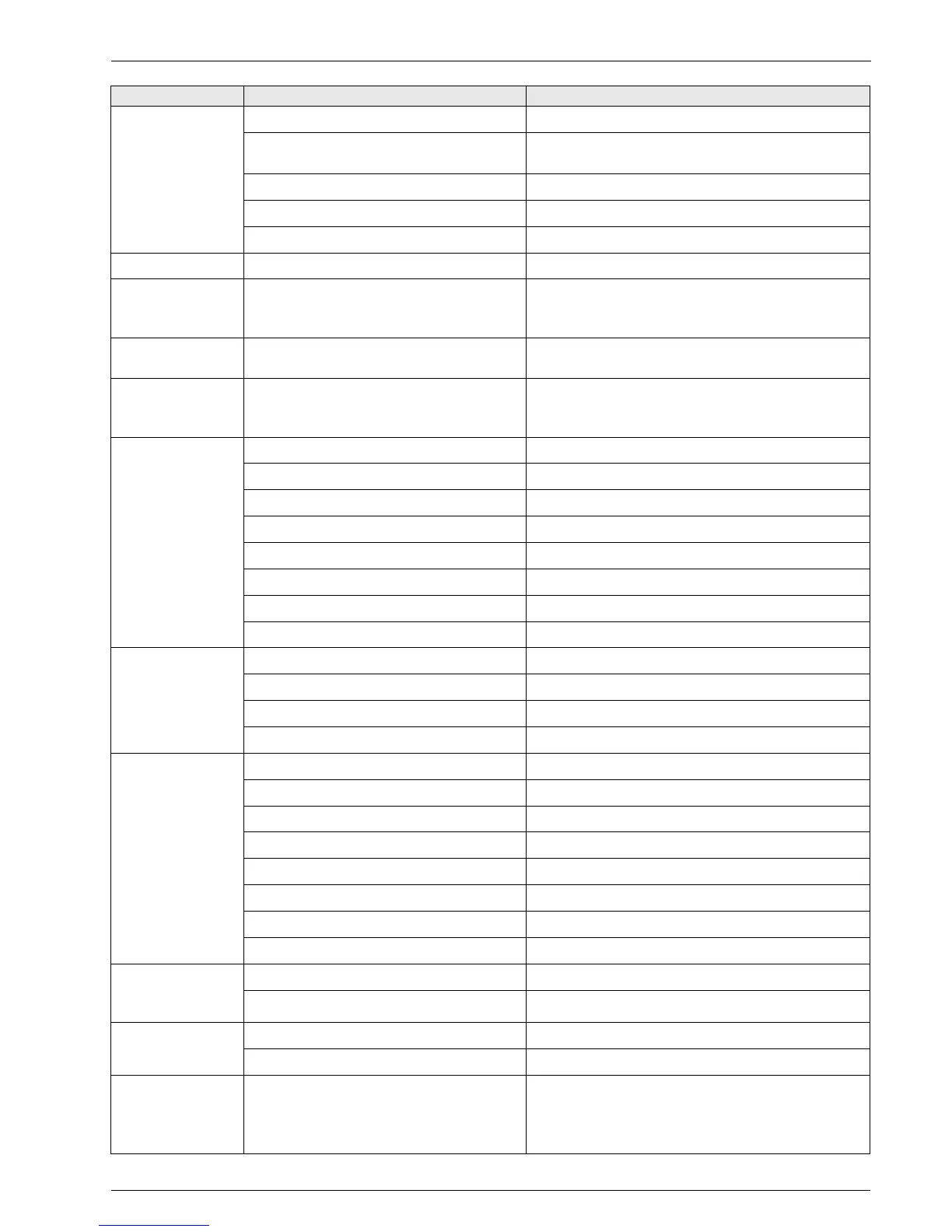

Tab. 9-2 Possible malfunctions on the A1 BO (Part 2)

Malfunction Possible cause Possible solution

Burner motor not running

despite burner demand

Plug connections of the control unit are loose

• Check/insert plug connections

Heater element or thermostat for preheating of the

heating oil defective

• Change oil preheater

Burner motor defective (bearing has seized)

• Change burner motor

Condenser defective

• Change condenser

Oil pump has seized

• Change oil pump

Burner starting is hard Start delay due to bad ignition

• Adjust ignition electrodes

Burner starts with blue

flame, but tears out at

intervals

Recirculation too large

• Reduce recirculation slightly

Flame has gold strands,

higher NOx-component

Recirculation too low

• Raise recirculation further

Flame is all blue and stable

in operation, but cold start

not possible

Recirculation too large

• Reduce recirculation slightly

No ignition Ignition electrodes short circuited

• Set/change ignition electrodes

Distance of ignition electrodes too large

• Set ignition electrodes

ignition electrodes contaminated or humid

• Clean ignition electrodes, check oil nozzle and burner setting

Ignition electrodes burnt out

• Change ignition electrodes

Insulating body cracked

• Change ignition electrodes

Ignition transformer defective

• Replace ignition transformer

Ignition cable burnt

• Change ignition cable and determine the cause

Automatic firing unit faulty

• Change automatic firing unit

Loud, whistling

mechanical noise

Oil pump is suctioning air

• Check bolts

Vacuum in the oil line too high

• Clean the filter, open valves fully

Burner motor bearing defective

• Change burner motor

Oil pump defective

• Change oil pump

Oil pump does not pump

any oil

Stop valve at oil filter or in suction line closed

• Open stop valve

Oil pump gear damaged

• Change oil pump

Suction valve has leakage

• Clean/change suction valve

Oil line has leakage (pump suctions air)

• Check bolts

Filter clogged

• Clean the filter

Filter not leakproof

• Change filter

Oil pump power insufficient

• Change oil pump

Clutch defective

• Change clutch

Oil atomisation not

uniform – heavy soot

deposit in flame tube

Oil nozzle loose, clogged or worn out

• Check/tighten/change oil nozzle

Oil nozzle spraying angle is wrong

• Replace oil nozzle

No oil flow Oil nozzle clogged

• Replace oil nozzle

LE membrane valve clogged

• Change LE membrane valve or oil preheater

Mixer device has thick

layer of oil or heavy

carbon deposits

Air supply insufficient

• Check air supply line for clogging

• Use air supply lines with larger cross-section

• Ambient air dependent operation: Check air supply opening

(min. 150 cm

2

unlockable air supply opening)

Loading...

Loading...