3x Set-up and Installation

18

FA ROTEX A1 BO - 10/2007

3.5.2 Connecting the flue gas pipe to the oil condensing boiler

Requirements:

– The flue system fulfils the requirements described in section3.5.1.

– The flue system fulfils any other required national or regional safety requirements.

– The oil condensing boiler is correctly connected.

Connection:

• Connect the oil condensing boiler to the flue system in the installation room (for connection dimensions refer to fig 3-6 and

tab. 3-4).

• Place the nameplate of the flue gas pipe in the installation room.

Tab. 3-4 Connection dimensions for the LAS connection of the oil condensing boiler

14 478 (ref. to chapter 3.5.1):

We recommend using the associated ROTEX flue gas kits (see fig 3-5). They satisfy all requirements and are

also fitted with special acid-proof seals.

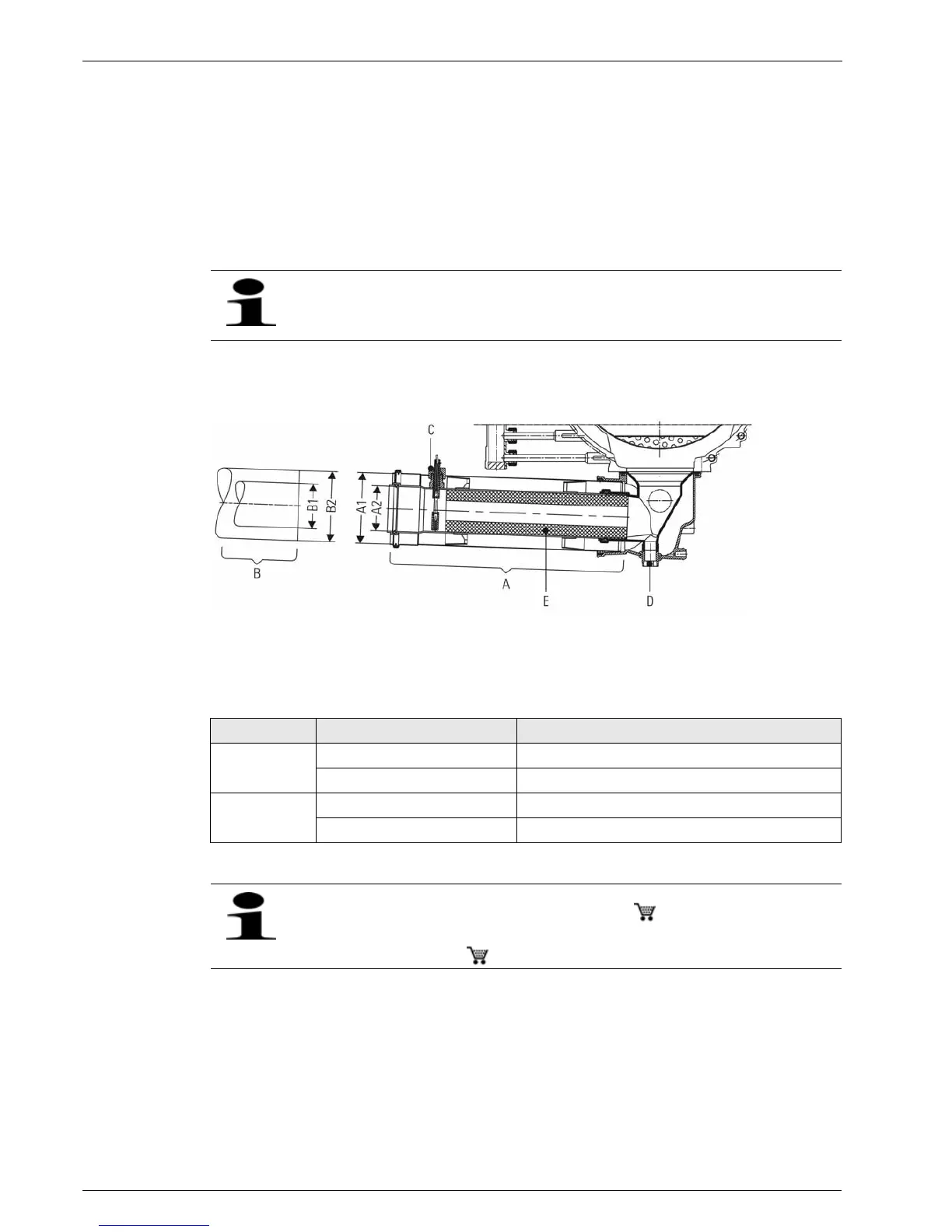

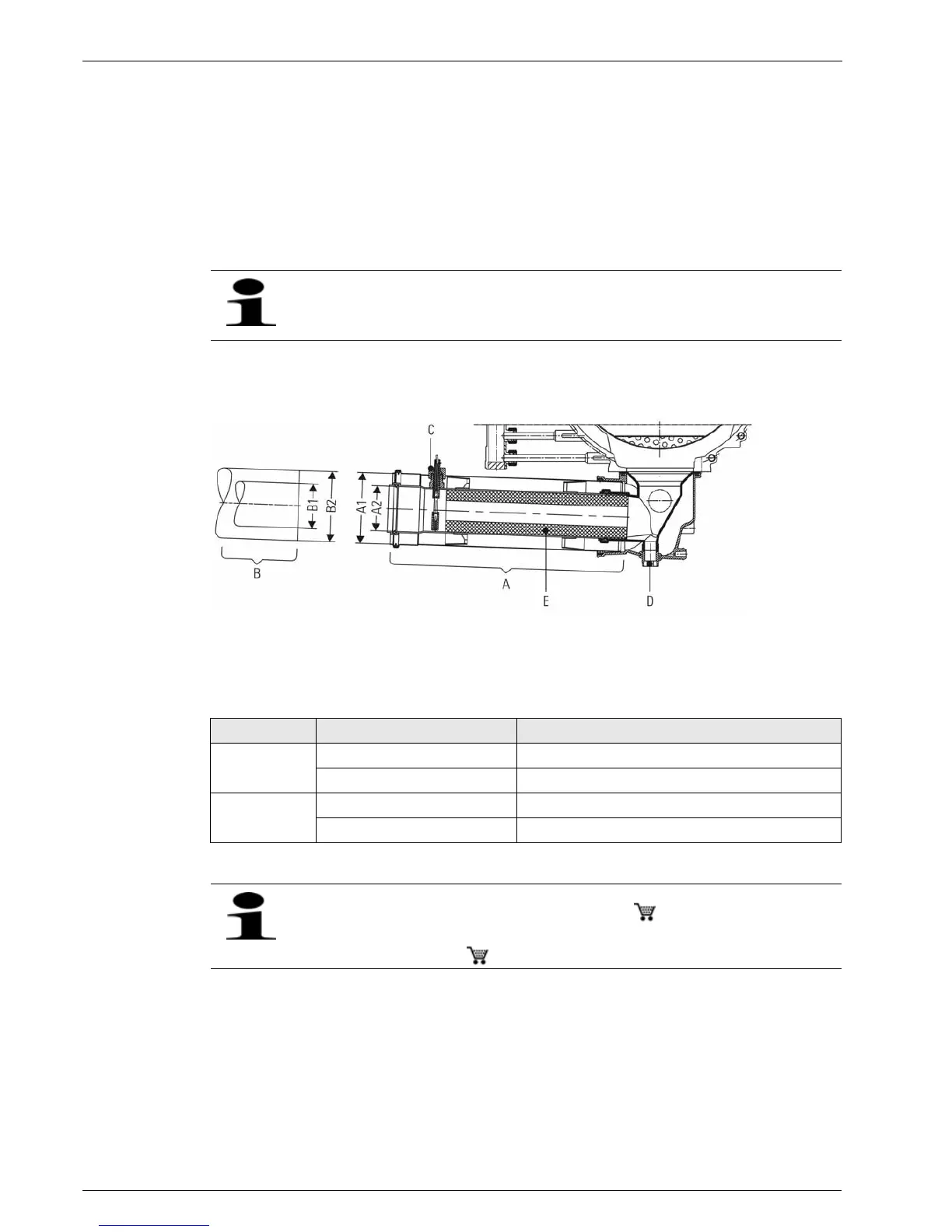

Fig. 3-6 Connection dimensions LAS Twin skin flue of oil condensing boiler of series A1 BO

A Boiler connection

B Flue gas connection

C Flue gas temperature sensor

D Connection for condensate drain

E Flue gas noise damper (not in A1 BO 35i)

Connection side Connection Connection dimension in mm

A Boiler side A1 Flue gas DN 80 Collar Inner diameter = 80.4 +0.8

A2 Supply air DN 125 Collar Inner diameter = 127.0 –0.5

B Flue gas side B1 Flue gas DN 80 Outer diameter = 80.0 +0.3

B2 Supply air DN 125 Outer diameter = 126.0 ±0.3

In some cases, the resonance in the flue system can amplify the noise at the mouth of the flue gas pipe.

The noise level can be effectively reduced by using a noise damper ( 15 45 78).

Air suction noises are generated during ambient air-dependent operation. The noise level can be effectively

reduced by using a noise damper ( 15 45 77).

Loading...

Loading...