9 x Faults and malfunctions

62

FA ROTEX A1 BO - 10/2007

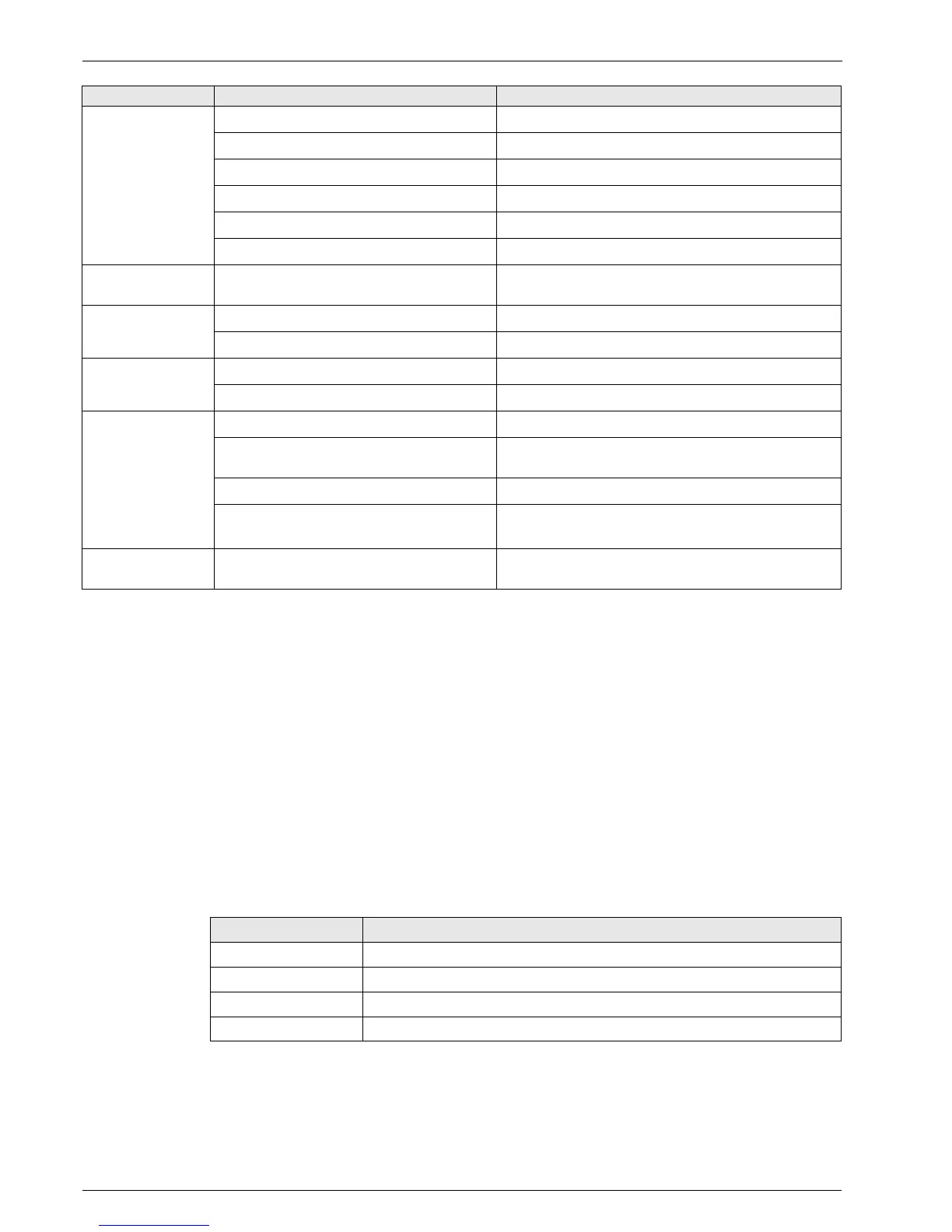

Tab. 9-3 Possible malfunctions on the A1 BO (Part 3)

9.3 Control unit fault signals

The control unit detects malfunctions, e.g. sensor disruptions or short-circuits. The type of malfunction is displayed via a fault

code. The fault codes are explained in the documentation of the relevant ROTEX control.

9.4 Burner malfunctions

The LED in the reset button of the automatic firing units (fig 6-1, pos. 9) indicates the processes of the burner control. In the

normal mode, the LED transmits a brief flashing signal, followed by a long pause.

LED display in the event of a malfunction:

– LED burns steadily, the burner is shut off and locked.

– The continuous lighting is interrupted every 10 seconds and a flash code is broadcast which gives information about the

cause of the last fault.

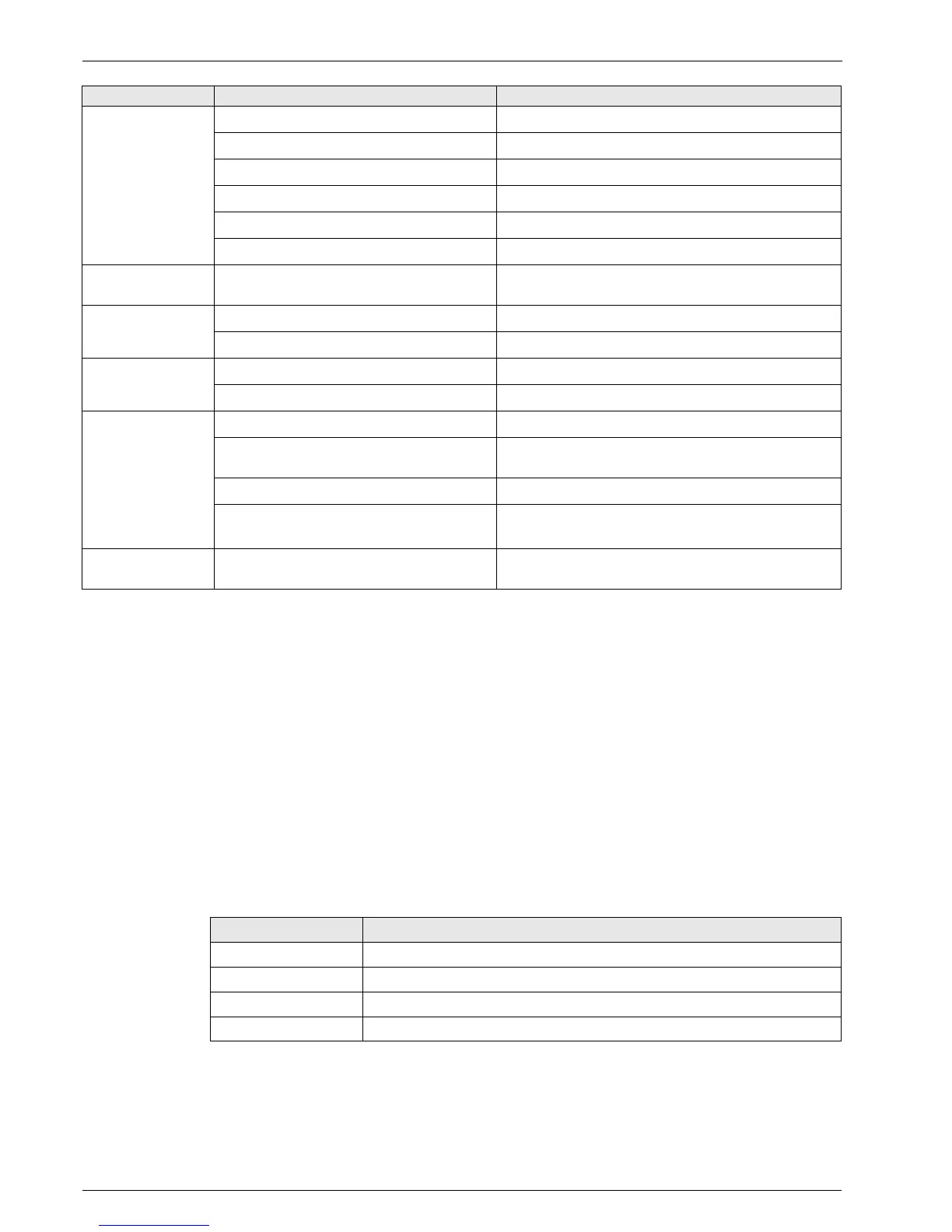

Fig. 9-1 Fault codes of the automatic firing units

I short signal

l long signal

— Pause

Malfunction Possible cause Possible solution

Mixer device has thick

layer of oil or heavy

carbon deposits

Air supply line contaminated/clogged

• Clean air supply line

Flue gas pipe of the LAS is leaking

• Seal the flue gas pipe, change seal

Burner setting wrong

• Check/correct burner setting

Oil nozzle is wrong size

• Check/change nozzle type

Combustion air quantity wrong

• Measure fan pressure, correct burner setting

Suction line draws air (leakage)

• Seal suction line

Soot formation on the

air nozzle

Recirculation too low

• Open recirculation slightly

Solenoid valve at oil

pump does not open

Coil defective

• Change coil

Automatic firing unit faulty

• Change automatic firing unit

Automatic flame guard

does not actuate

Flame guard contaminated or defective

• Clean or change flame guard

Glass on light tube dirty

• Clean or change glass or light tube

STL switch off Water throughput too low due to air inclusion

• Vent system

Water flow too low due to valves closing too quickly

along the entire heating network

• Use slow closing or timed valves, if needed, install overflow valve

Pump standstill

• Check network connection, change pump if necessary

Storage tank switched off in operation without

hot water storage tank

• Disconnect storage temperature sensor

• Switch off storage tank charging circuit

Flue gas temperature

sensor switch off

Flue gas temperature too high

• Clean the boiler

Flash Code Cause of the fault

l l l l l No flame signal within safety period

l l l l l External light during pre-ventilation time/ pre-ignition time

l l l l l Contact release thermostat does not close within 400 s

l l l l l — l l l l l Manual fault shutdown

Loading...

Loading...