Page 39

ROYAL ENFIELD 350cc and 500cc O.H.V. WORKSHOP MANUAL

With the ignition switch in the "OFF"

position, start the engine.

Slowly increase the speed of the engine until

the voltmeter needle "flicks" and then steadies.

Note this value and stop the engine.

If this value lies outside the limits given in

paragraph 2(b), the regulator setting must be

adjusted.

If the value is within the limits, examine the

cut-out as described in paragraph 3(c).

(e) Adjusting the electrical setting of the regulator

Adjustment of the regulator requires removal

of the control box cover. This is facilitated by

removing the control box from the machine and

providing temporary connections. Loosen the

control box cover securing clips by slackening

the securing screws set in the base of the control

box, and lift off the cover.

It is important that regulator adjustments are

carried out with the control box supported in a

similar position to that on the machine.

Restart the engine.

Slacken the locknut of the regulator adjusting

screw (see Fig. 2) and turn the screw in a

clockwise direction to raise the setting or an

anti-clockwise direction to lower the setting.

Turn the screw only a fraction of a turn at a time

and then tighten the locknut. Repeat as above

until the correct setting is obtained.

Adjustment of regulator open-circuit voltage

should be completed within 30 seconds;

otherwise heating of the shunt winding will

cause false settings to be made.

Stop the engine.

Remake the original connections and replace

the cover. Ensure that the cover seats correctly

on the sealing washer.

N.B.-A dynamo run at high speed on open

circuit will build up a high voltage. Therefore,

when adjusting the regulator, do not run the

engine up to more than half throttle or a false

setting will be made.

(d) Checking the electrical setting of the

cutout

If the regulator is correctly set but the battery

is still not being charged, the cut-out may be out

of adjustment.

Replace the control box in the testing

position, remake the temporary connections and

remove the control box cover. Connect a

voltmeter between terminals "D" and "E."

Start the engine and slowly increase the

speed until the cut-out contacts close. Note the

voltage at which this occurs and stop the

engine. This should be 6.3-6.7 volts. If

operation of the cut-out takes place outside

these limits, it will be necessary to adjust.

(e) Adjusting the electrical setting of the

cutout

Restart the engine.

Slacken the locknut securing the cut-out

adjusting screw and turn the adjusting screw in a

clockwise direction to raise the voltage setting or

in an anti-clockwise direction to reduce the

setting.

Turn the screw only a fraction of a turn at a

time and then tighten the locknut. Test after each

adjustment by increasing the engine speed and

noting the voltmeter reading at the instant of

contact closure.

Stop the engine.

Electrical setting of the cut-out, like the

regulator, must be made as quickly as possible

because of temperature-rise effects. Tighten the

locknut after making the adjustment.

N.B.-if the cut-out does not operate, there

may be an open-circuit in the wiring of the

cut-out and regulator unit, in which case the unit

should be removed for examination or

replacement.

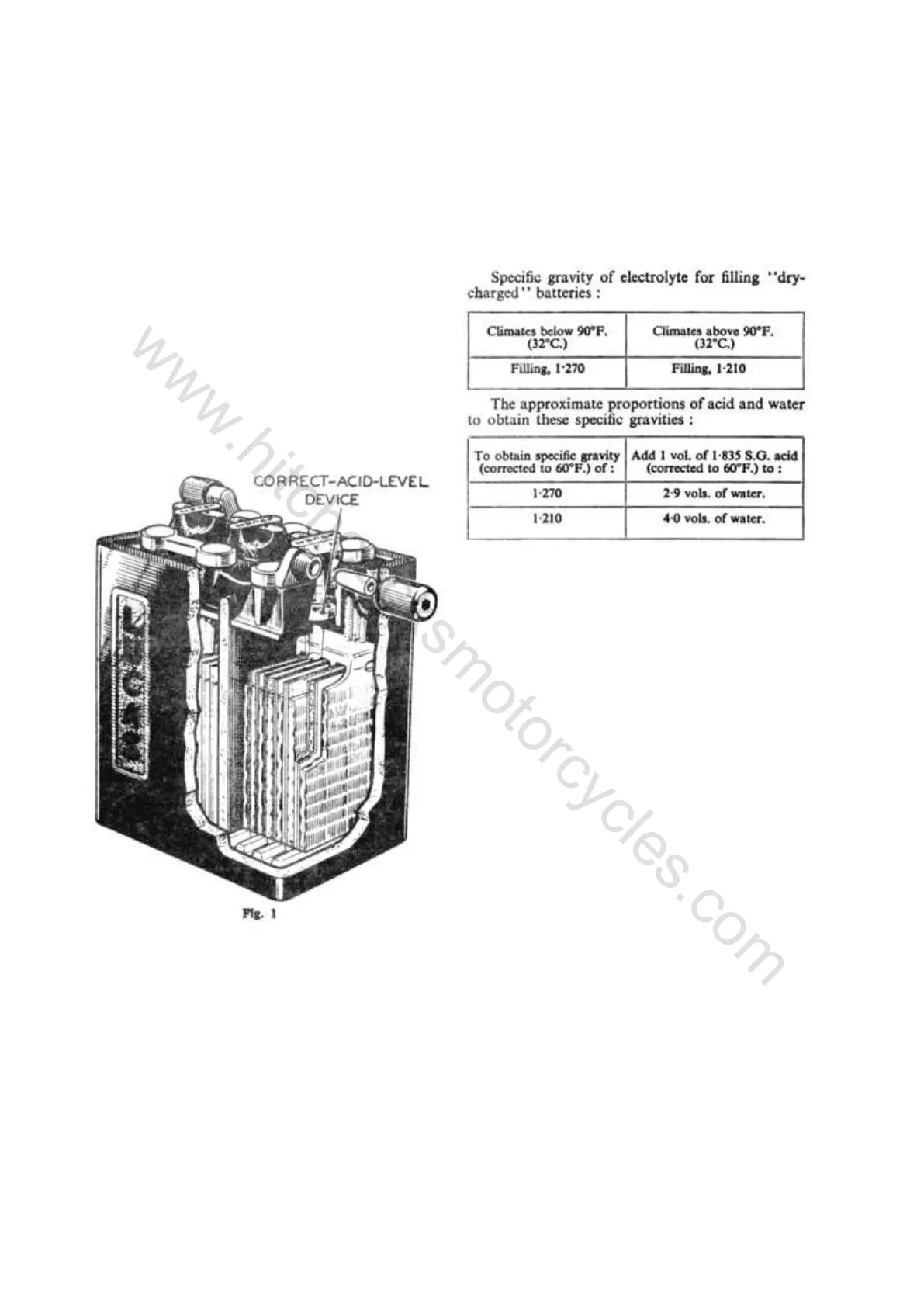

1. General

The model PUZ7E (see Fig. 1) is a

"drycharged" battery and is supplied without

electrolyte but with its plates in a charged

condition. When the battery is required for

service it is only necessary to fill each cell with

sulphuric acid of the correct specific gravity. No

initial charging is required, but the battery must

be left to stand at least one hour after filling

before putting the machine into service and then

adjusting the acid level if necessary.

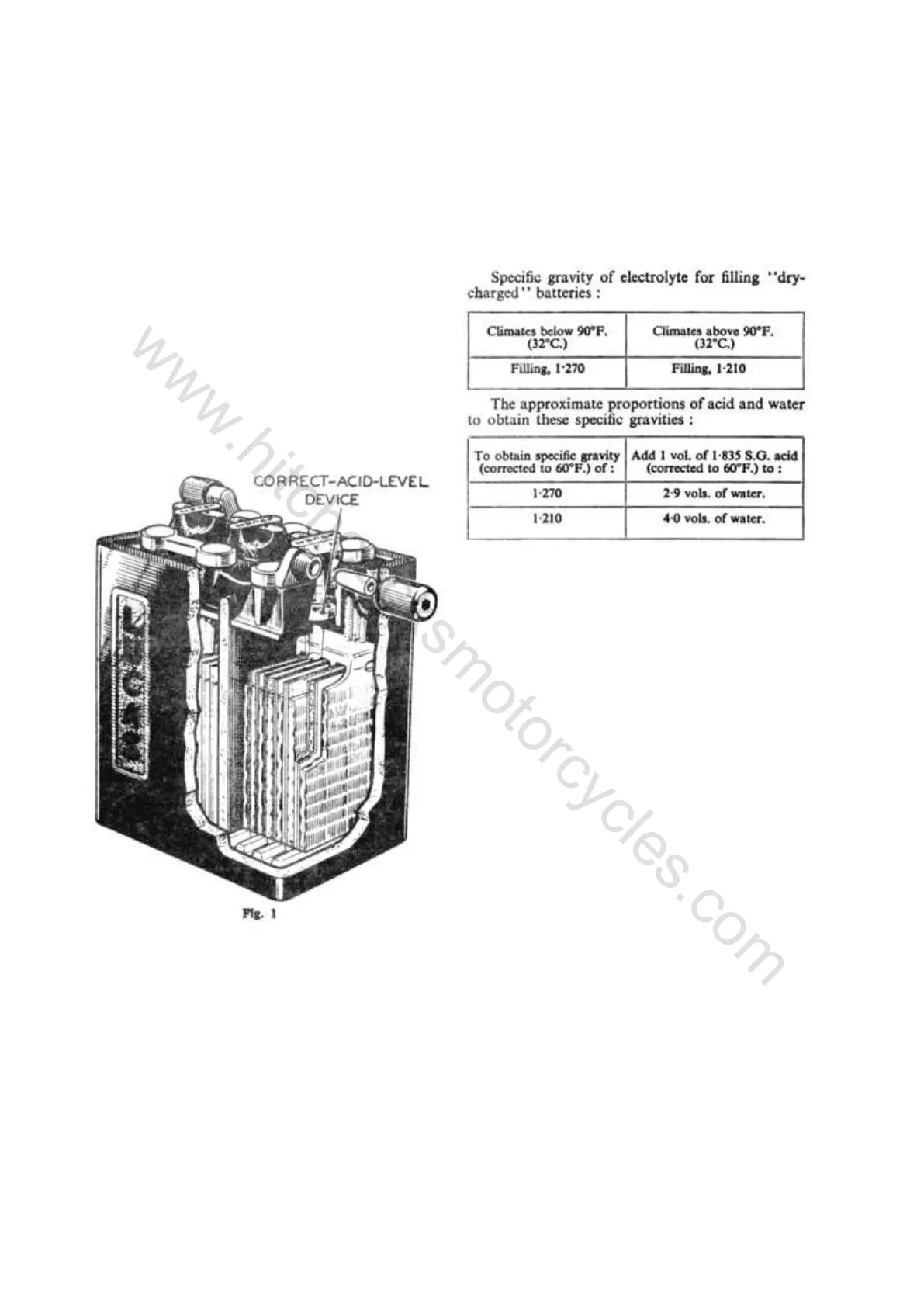

2. Preparation for Service

The electrolyte is prepared by mixing together

distilled water and concentrated sulphuric acid,

using lead-lined tanks or suitable glass or

earthenware vessels. Slowly add the acid to the

water, stirring with a glass rod. Never add water

to the acid, as this causes dangerous spurting of

the concentrated acid. The specific gravity of the

filling electrolyte depends on the climate in

which the battery is to be used.

Heat is produced by the mixture of acid and

water, the electrolyte should be allowed to cool

before pouring it into the battery.

The specific gravity of the electrolyte varies

with the temperature. For convenience in

comparing specific gravities, they are always

corrected to 60° F., which is adopted as a

reference temperature.

The method of correction is as follows :

For every 5°F. below 60°F., deduct .002 from

the observed reading to obtain the true specific

gravity at 60°F. For every 5°F. above 60°F. add

.002 to the observed reading to obtain the true

specific gravity at 60°F.

The temperature must be that indicated by a

thermometer having its bulb actually immersed

in the electrolyte and not the ambient

temperature.

Fill the cells to the tops of the separators, in

one operation. The battery filled in this way is

90% charged. When time permits, a short

freshening charge for no more than four hours at

the normal recharge rate of 1.5 amp. should be

made.

3. Routine Maintenance

Fortnightly (or more frequently in hot

climates) examine the level of electrolyte in the

cells and if necessary add distilled water to bring

the level up to the tops of the separators. The use

of a Lucas Battery Filler will be found helpful,

as it ensures that the correct electrolyte level is

automatically maintained and also prevents

distilled water from being spilled on the top of

the battery (see Fig. 2).

Occasionally check the terminals, clean and

coat them with petroleum jelly. Wipe away all

www.hitchcocksmotorcycles.com

Loading...

Loading...