1. Description of Frame

The frames used on the above models are

basically identical, with swinging arm rear

suspension, but there are some small

differences in the lugs for engine attachment,

the method of attachment of the pivot point for

the swinging arm and in the width between the

brackets supporting the upper ends of the rear

suspension units. For part numbers of frames

see appropriate spares lists.

The frame is built throughout of cold drawn

weldless steel tubing with brazed or welded

joints, liners being fitted where necessary for

extra strength. All the main frame members

are made of chromemolybdenum alloy steel

tubing which retains its strength and resistance

to fatigue after brazing or welding.

The swinging arm unit which forms the

chain stays is provided with large diameter

phosphor bronze bushes and pivots on a stout

steel tube which is secured to the main frame

by a long bolt passing through the pivot lugs.

Hardened steel thrust washers are provided to

deal with side thrust. The torsional rigidity of

the swinging arm unit helps to maintain the

rear wheel upright in the frame and thus

relieves the wheel spindle of bending stresses

to which it is subject with other types of rear

suspension.

2. Steering Head Races

The steering head races, 34085, are the

same at the top and bottom of the head lug and

are the same for all models. They are easily

removed by knocking them out with a hammer

and drift and new races can be fitted either

under a press or by means of a hammer and a

wooden drift.

3. Removal of Rear Suspension Unit

The rear suspension units are readily

removed by undoing the top pivot pin nut,

driving out the pivot pin, then hinging the

suspension unit back on the lower pivot pin,

removing the lower nut and pushing the

suspension unit off the pivot pin welded to the

fork end.

4. Servicing Rear Suspension units

(a) Proprietary Units. The proprietary units

fitted to most 1954 and all 1955 models are

sealed and servicing of the internal mechanism

can be carried out only by the manufacturers.

The rubber bushes in the top and bottom

eyes can easily be renewed and the spring can

be removed by pushing down on the top spring

cover so as to release the split collar above it.

After removal of the split collar the top cover

and spring can be lifted off.

When reassembling, the spring should be

greased to prevent rust and squeaking if it

should come into contact with either of the

covers.

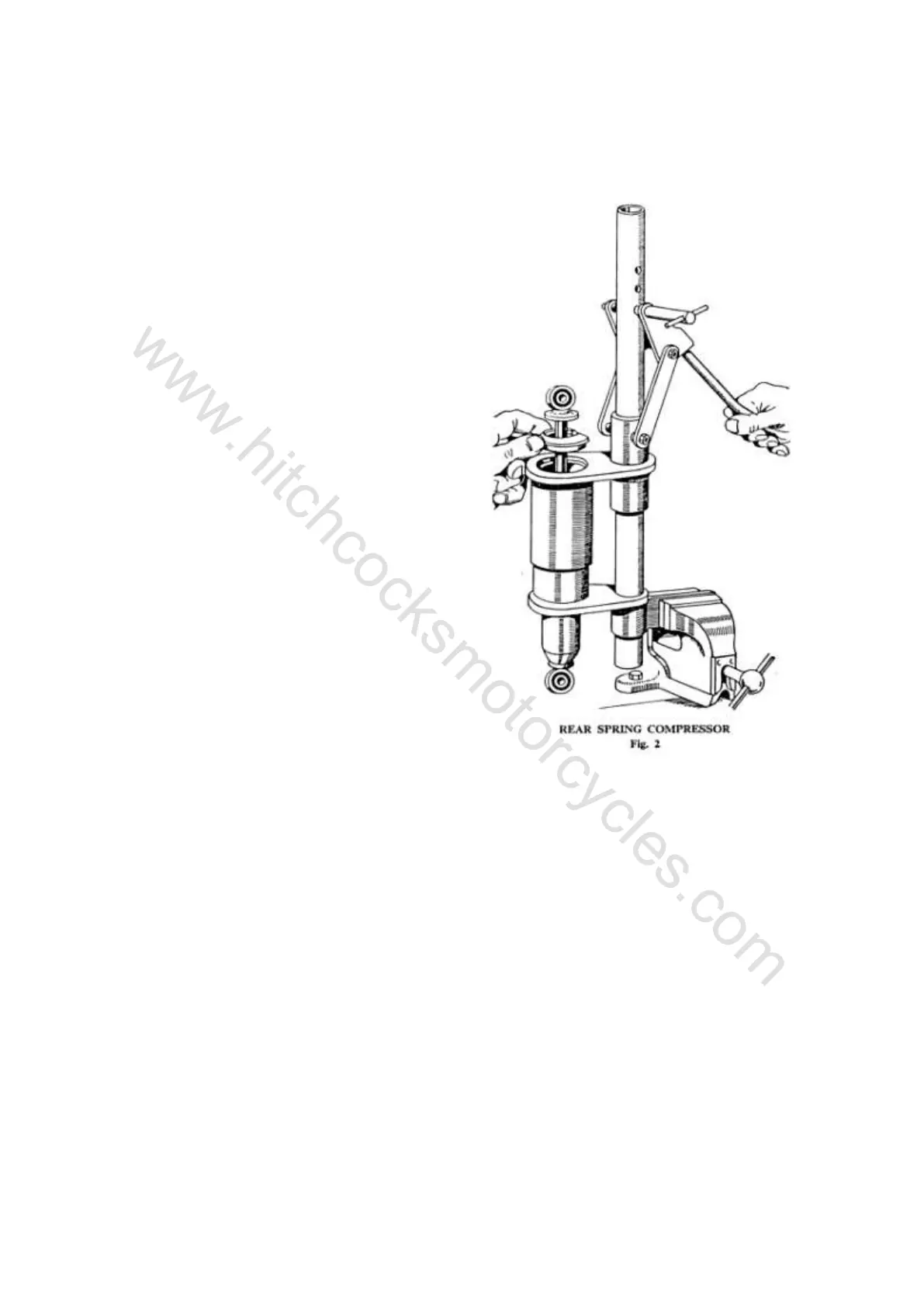

The standard solo springs have a rate of

100105lb. per inch and it is not difficult to

compress these by hand. Heavier springs

having a rate of 130lb. per inch are available

which may require the use of a spring

compressor, as shown in Fig. 2.

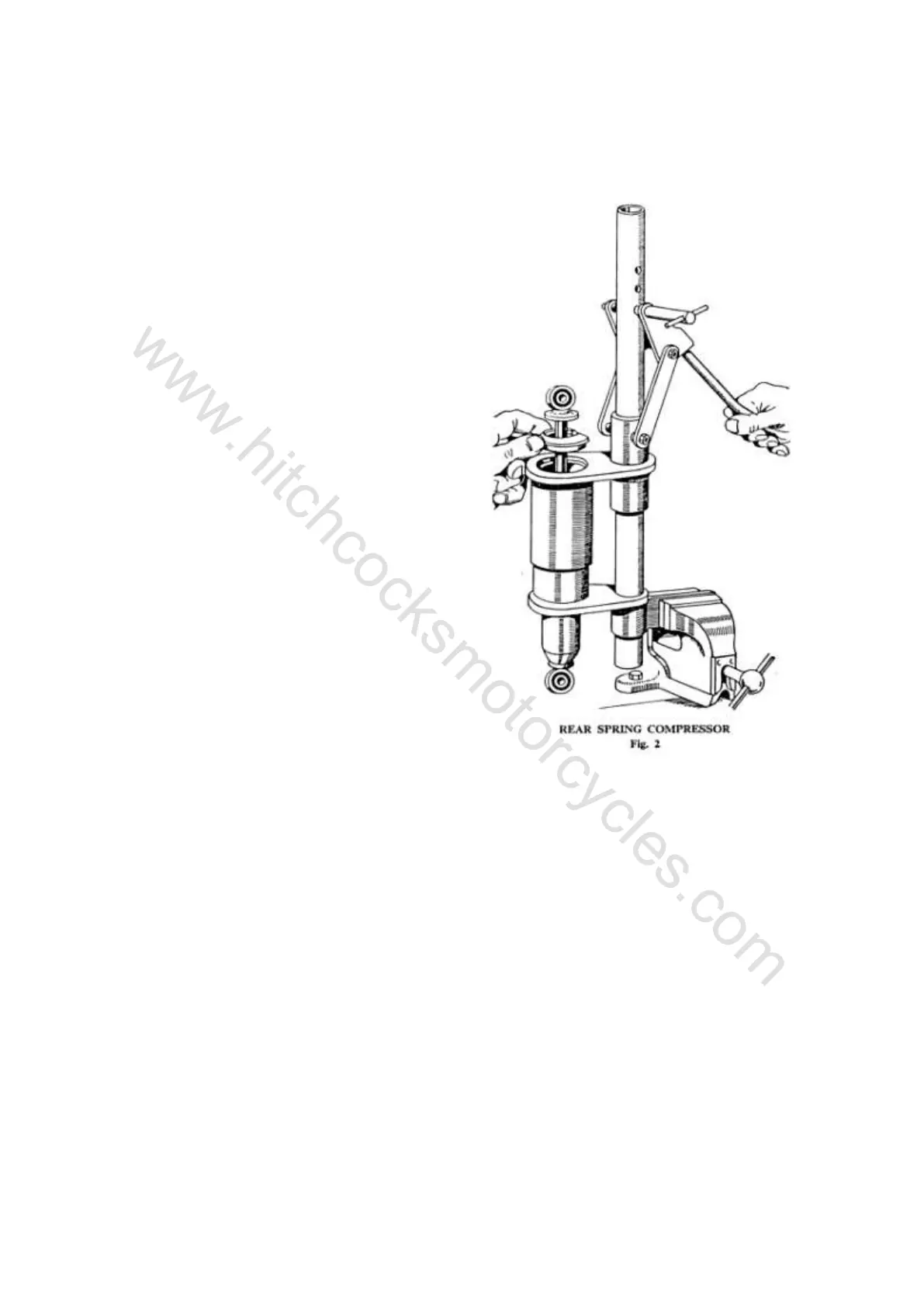

(b) Royal Enfield Units. Mark 1. Enfield

rear suspension units, Part Number 34276 or

36451, are shown in Fig. 3. Units having Part

No. 34276 are fitted with springs of .252 in.

diameter wire (Part No. 34284) having a

rating of approximately 200lb per inch (when

fitted on the scrolls).

Loading...

Loading...