Page 51

ROYAL ENFIELD 350cc and 500cc O.H.V. WORKSHOP MANUAL

removal of the main tube bush the bottom tube

bush, oil seal housing and oil seal can be

removed.In case of difficulty in removing the main

tube bush it is possible to withdraw the oil seal

housingafter loosening the crown clip bolt 39038,

removing the plug screw 38968 and unscrewing

the main tube from the fork-head by means of a

hexagon bar .500 in. across flats (Unbrako wrench

W. 11) or the special tool shown in Fig. 2.

4. Spring

Solo and Sidecar springs are available. The free

length of each is 20.1/2 ins. The spring should be

replaced if it has closed by more than 1 inch.

5. Reassembly of Parts

When refitting the oil seal, or fitting a new one,

great care must be exercised not to damage the

synthetic rubber lip which forms the actual seal. If

the seal has been removed from the upper end of

the main tube and is refitted from this end a

special nose piece (Fig. 3) must be fitted over the

end of the tube to prevent the thread from

damaging the oil seal.

The spring stud is a tight fit in the hole at the

lower end of the bottom tube. Once the stud has

been entered in the hole push the bottom tube

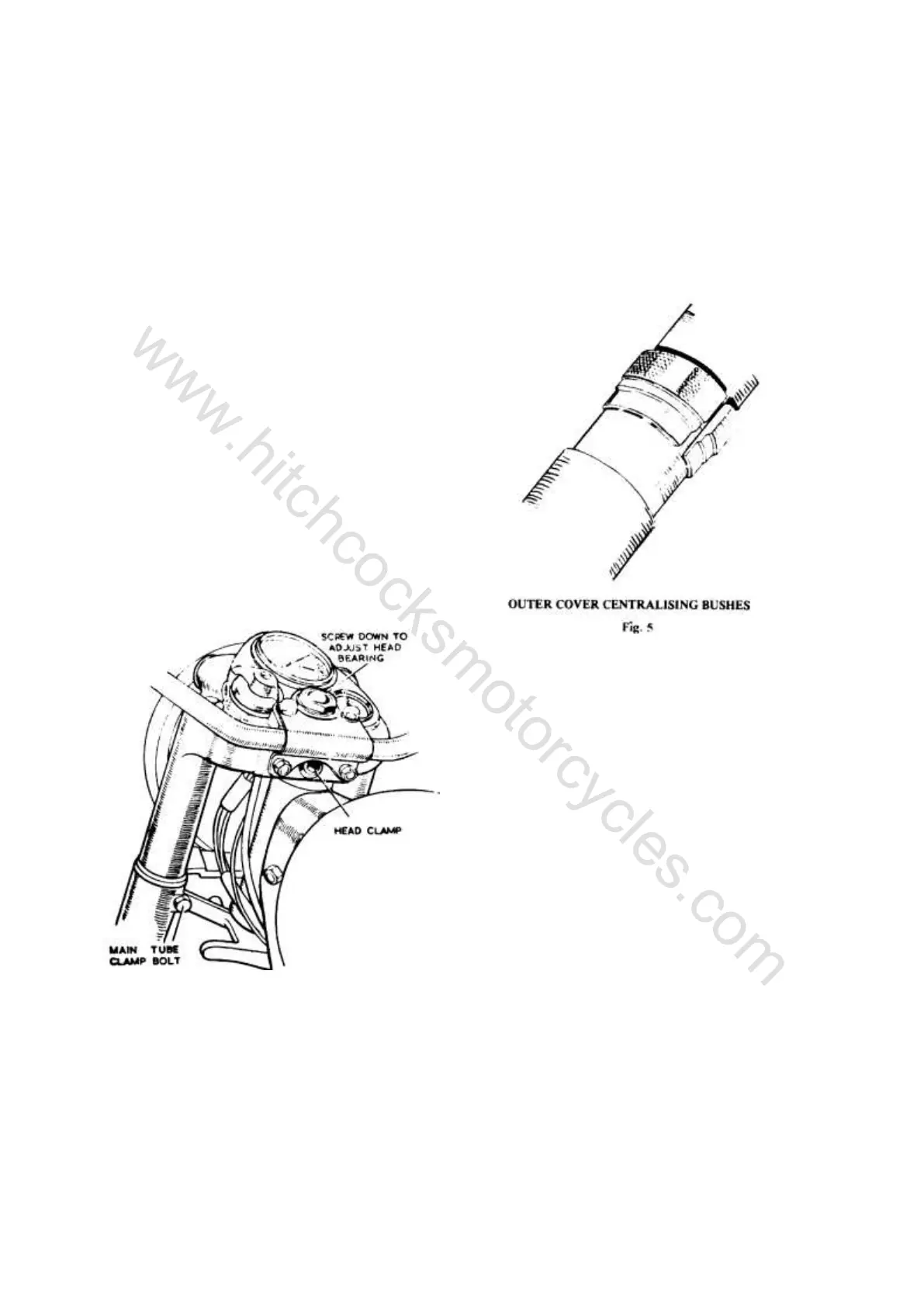

SHOWING THE POSITIONS OF THE CLAMP BOLTS

SECURING THE STEERING STEM AND FORK TUBES

Fig. 4

up sharply against the spring until two or three

threads on the stud project beneath the end of

the bottom tube. Now fit the nut and washer and

pull the stud into position by tightening the nut.

If necessary fit the nut first without the washer

until sufficient thread is projecting to enable the

washer to be fitted.

6. Steering Head Races

The steering head bearing consists of two

deep groove thrust races each containing

nineteen 1/4 in. diameter balls. The bearing is

adjusted by tightening the steering stem locknut

after loosening the ball head clip screw and both

the fork crown clamp bolts. The head should be

adjusted so that, when the front wheel is lifted

clear of the ground, a light tap on the handlebars

will cause the steering to swing to full lock in

either direction, while at the same time there

should be only the slightest trace of play in the

bearings. When testing for freedom of

movement the steering damper, if fitted, should

be disconnected by unscrewing the anchor plate

pin. Do not forget to tighten the ball head clip

screw and fork crown clamp bolts. Before

tightening the latter make sure that the cover

tubes are located centrally round the main tubes

so that the bottom tube does not rub inside the

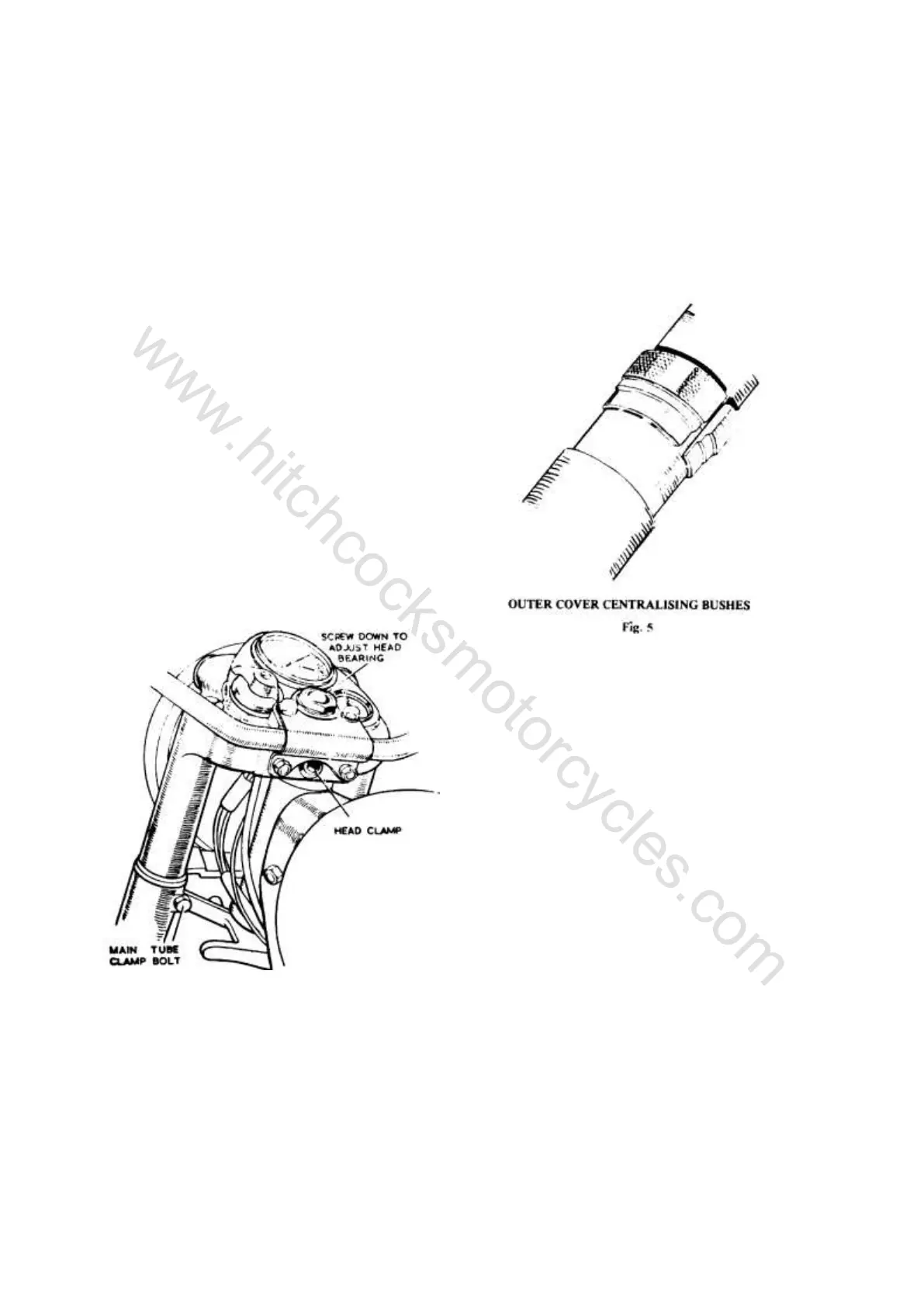

cover tube. A pair of split bushes (Fig. 5) is

useful to ensure centralisation of the cover tubes.

7. Removal of Complete Fork

The fork complete with front wheel and

mudguard can be removed from the machine if

necessary by adopting the following procedure.

full of oil. Upward movement of the wheel

spindle forces oil from the lower chamber "A"

through the annular space between the spring

stud (38067) and the bore of the main tube valve

port (38138) into the damper chamber "B."

During this stroke the pressure on the underside

of the valve plate (38073) causes this to lift so

that oil can also pass from "A" to "B" through

the eight holes in the valve body. Since,

however, the diameter of chamber "B" is less

than that of chamber "A" there is not room in

"B" to receive all the oil which must be displaced

from "A" as the fork operates. The surplus oil

passes through the cross hole in the spring stud

and up the centre hole in the stud, spilling out

through the nut (38076) which secures the upper

end of the spring stud to the bronze guide at the

lower end of the fork spring.

On the rebound stroke the oil in the damper

chamber "B" is forced through the annular space

between the spring stud and the bore of the main

tube valve port. During this stroke pressure in

chamber "B" closes the two disc valves at the

upper and lower ends of the chamber so that the

only path through which the oil can escape is the

annular space between the spring stud and the

port. Damping on the rebound stroke is therefore

heavier than on the bump stroke. At the extreme

end of either bump or rebound stroke a small

taper portion on the spring stud enters the bore

of the valve port, thus restricting the annular

space and increasing the amount of damping. At

the extreme end of the bump stroke the larger

diameter taper on the oil control collar (38075)

enters the main counterbore of the valve port

thus forming a hydraulic cushion to prevent

metal to metal contact.

3. Dismantling the Fork to Replace Spring,

Oil Seal or Bearing Bushes

Place the machine on the centre stand,

disconnect the front brake control and remove the

front wheel and mudguard complete with stays.

Unscrew the bottom spring stud nut (38080)

which will allow oil to run out of the fork down

to the level of the cross-hole in the spring stud.

Now knock the spring stud upward into the fork

with a soft mallet, thus allowing the remainder

of the oil to escape. Pull the fork bottom tube

down as far as possible, thus exposing the oil

seal housing (38157). Unscrew this housing

either by means of a spanner on the flats with

which it is provided or by using the gland nut

handgrips (E.5417). The bottom tube can now

be withdrawn completely from the main tube,

leaving the bottom tube bush, oil seal housing

and oil seal in position on the main tube.

Now unscrew the main tube valve port using

"C" spanner (E5418). The spring stud and

spring can now be withdrawn from the lower

end of the main tube.

The steel main tube bush (38156) can now

be tapped off the lower end of the tube, if

necessary using the bottom tube bush for this

purpose. Before doing this, however, it is

advisable to mark the position of the bush with

a pencil line so as to ensure reassembling it in

the same position on the main tube. The reason

for this is that these steel bushes are finish

ground to size after fitting on to the tubes so as

to ensure concentricity to the main tube. After

www.hitchcocksmotorcycles.com

Loading...

Loading...