J Line Pump

Horizontal Double Suction Centrifugal Pump – API 610 Process Pump

36 V1.032818

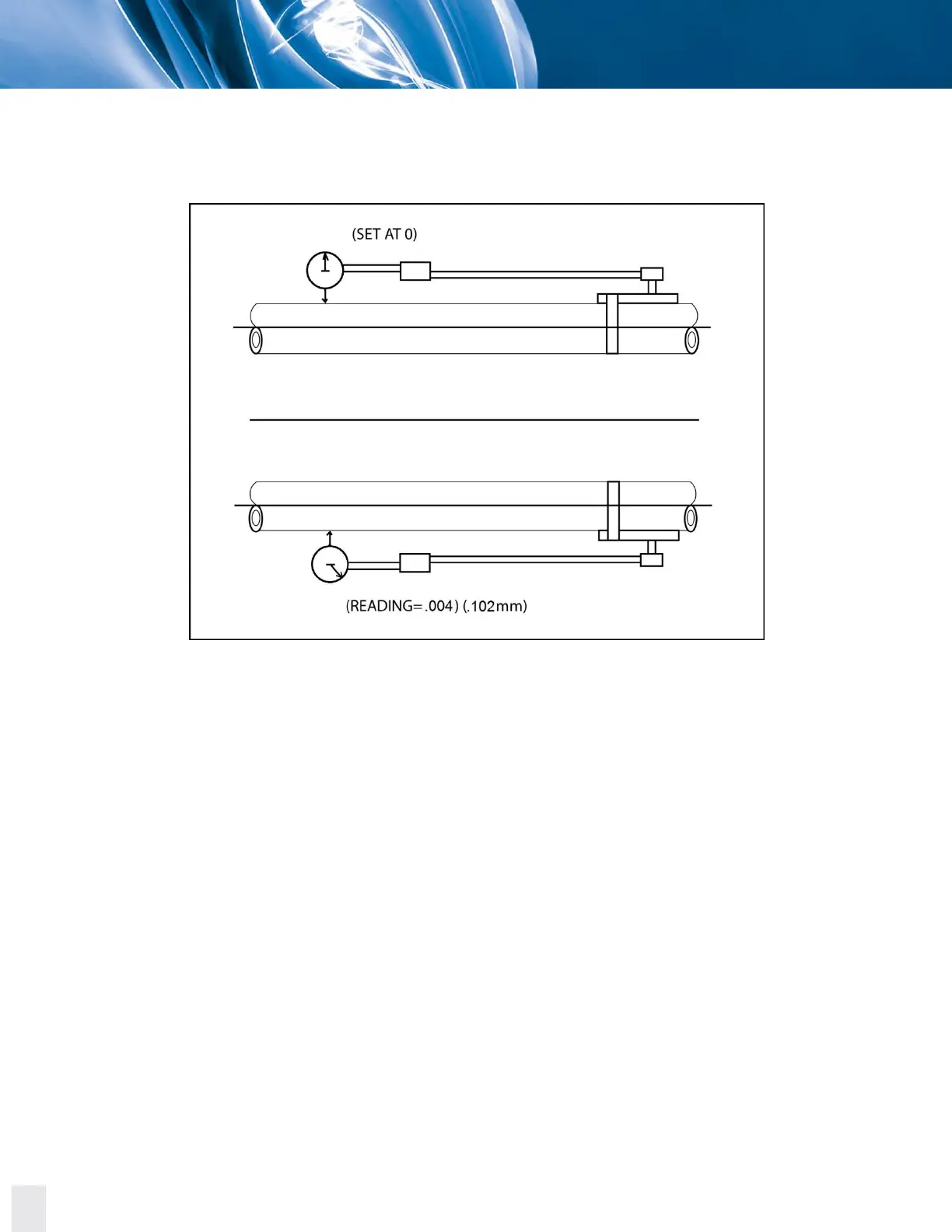

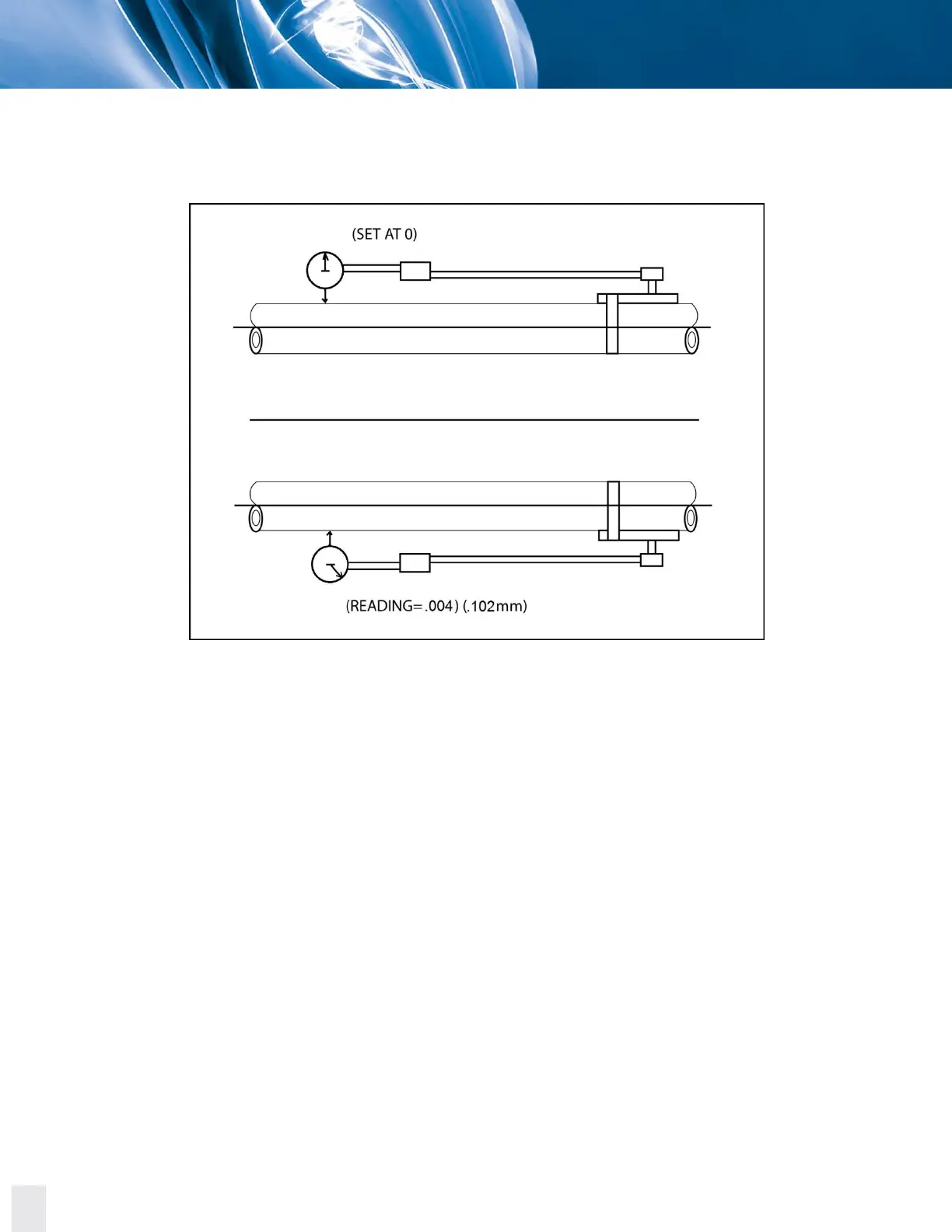

The next step is to determine indicator sag. Set up your bracket arrangement on a pipe. Set the indicator

at '0' on top. Roll set up until indicator is at the bottom of pipe. It will read negative. In this example, it

was found to be -0.004 inch (-0.102 mm).

Figure 5.9. Indicator sag in across the disc pack alignment analysis example.

With the indicator bracket attached to the pump hub, reading out the center member a convenient

distance, (in this example 8 inches [203.2 mm] was used) rotate the unit in 90° increments and take

readings.

Bottom reading is then corrected for indicator sag. The indicator sag in the example was determined to

be -0.004 inch (-0.102 mm). The -0.004 inch (-0.102 mm) was subtracted from -0.025 inch (-0.635 mm)

indicator reading to give an actual of -0.020 inch (-0.508 mm) reading.

As this is a TIR (Total Indicator Reading) it is two times the actual center member center line location

relative to the pump shaft extension or -0.020 inch (-0.508 mm) / 2 inches (50.8 mm) = -0.010 inch

(0.254 mm). (What we are trying to do here is to determine the angle the center member makes with

respect to the pump shaft.)

A plus reading at the bottom indicates that the center member tips down as it extends away from the

pump. Using a scale of one small division on the graph equals 0.001 inch (0.0254 mm); plot the

0.010 inch (0.254 mm) as shown in the example.

Loading...

Loading...