47

English

SALMSON 08/2016

8.3 Other defaults

Other defects, not detected by the converter,

due to the pump.

WARNING! Risk of wound!

The liquid is toxic, corrosive or dangerous for

human being.

• The qualied person in charge of the repairing

must be informed.

• Clean the pump to ensure complete safety of the

operator.

9. Spare parts

Spare parts may be ordered via local approved

technicians and/or the Salmson after-sales ser-

vice.

To avoid any questions or wrong orders, all data

of the name plate should be mentioned when

ordering.

CAUTION! Danger of material damage!

Perfect pump function can only be guaranteed

when original spare parts are used.

• Only use original spare parts.

Subject to technical alterations!

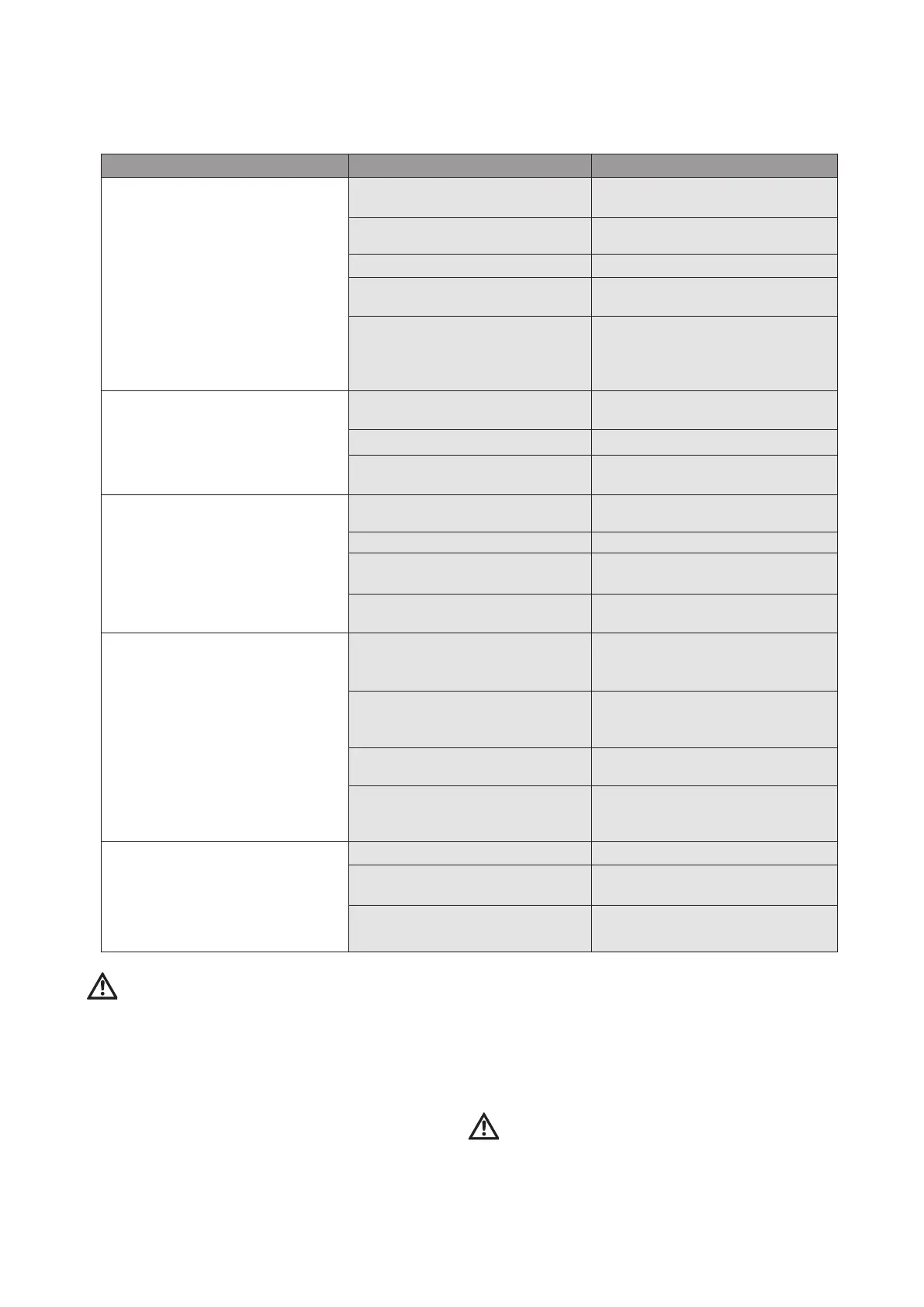

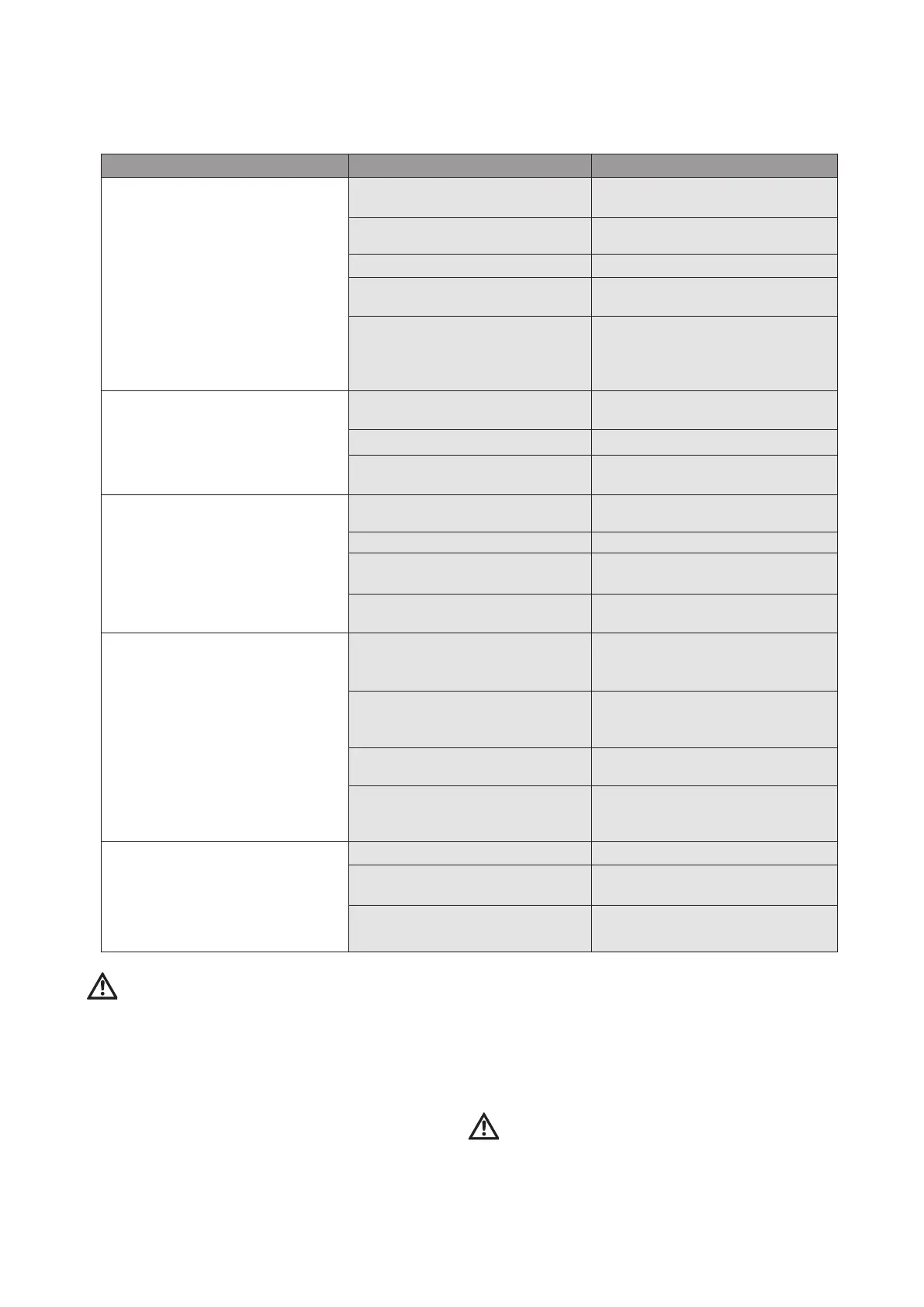

Defaults Possible causes Remedies

The pump is running but no

delivery

The pump does not run quickly enough Check the adequate adjustment of the

requirement (conformity to the setpoint).

The internal parts are obstructed by

particles

Let dismantle the pump and clean it.

Suction pipe is obstructed Clean the pipe.

Air in suction pipe Check tightness of the whole pipe up to

the pump and make it tight.

Suction pressure is too low, it causes

generally cavitation noise

Too high losses of load on suction or

suction head is too high (check the NPSH

of the pump installed and the installa-

tion).

The pump is vibrating Pump is loosed on its foundation Check and tighten completely the nuts

of the stud bolts.

Particles obstructing the pump Have the pump dismantled and clean it.

Difcult rotation of the pump Check the pump turns freely without

abnormal sticking.

No sufcient pressure for the

pump

The motor speed is not high enough Check if the setpoint is correctly adjus-

ted.

The motor is defective Replace it.

Bad lling of the pump Open the venting device and vent until

there are no more air bubbles.

The drain-priming plug is not fully tigh-

tened

Check it and screw it again.

The ow is irregular The suction head (Ha) is not observed Study again the installation conditions

and the recommendations described in

this instruction.

The suction pipe has a lower diameter

than the one of the pump

The suction pipe must have at least the

same diameter as the suction pump port.

The strainer and the suction pipe are

partially obstructed

Remove and clean.

In « Constant pressure » mode, the

pressure sensor is not adequate

Put a sensor with conforming pressure

scale and accuracy, see <chapter 4.4>.

In « Constant pressure » mode, the pump

does not stop if the ow is zero

The non-return valve is not tight Clean it or change it.

The non-return valve is not adequate Replace it by an adequate non-return

valve, see <chapter 4.4>.

The tank has low capacity due to the

installation

Change it or add an other one on the

installation.

Loading...

Loading...