44

English

SALMSON 08/2016

8. Faults, causes and remedies

Faults should only be remedied by qualied per-

sonnel! Observe the safety instructions.

Relays

The converter is tted with 2 output relays

aimed for an interface to centralized control.

ex.: control box, pumps control.

SBM relay :

This relay can be congured in the « Service »

menu < 5.7.6.0 > in 3 operating states.

State: 1 (factory setting)

« Available transfer » relay (normal operating for

this pump type).

The relay is activated when the pump runs or is

in a position to run.

When a rst defect appears or by mains supply

cutoff (the pump stops), the relay is deactiveted.

Information is given to the control box, regarding

the availability of the pump, even temporarily.

State: 2

« Run transfer » relay.

The relay is activated when the pump runs.

State: 3

« Power on transfer » relay.

The relay is activated when the pump is con-

nected to the network.

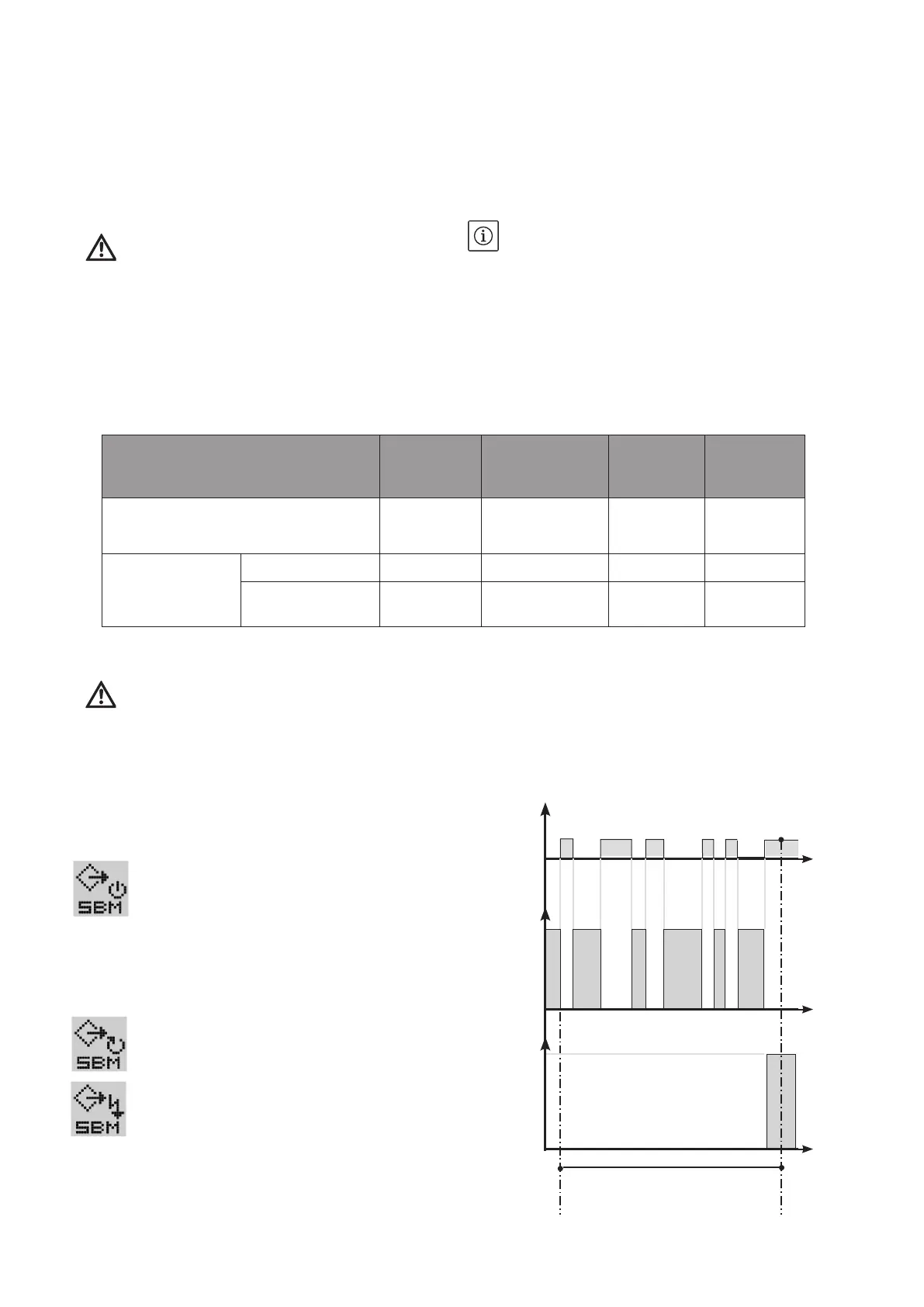

SSM relay:

« Failures transfer » relay.

After a series of detection (from 1 to 6 accord-

ing to signicance) of the same type of defect,

the pump stops and this relay is activated (up to

manual action).

Example: 6 defects with a variable time limit on

24 sliding hours.

State of SBM relay is « Available transfer ».

• In case of failure, do the lling in again and start

the operation again.

• Check that the current input does not exceed

the value indicated on the motor-converter data

plate.

7. Maintenance

DANGER! Before working on equipment, switch

it off and prevent it from being switched on

again!

• No special maintenance in operation.

• The bearing holding the coupling and the motor

bearings are lubricated for their total lifetime and

do not require any lubrication.

• Keep the pump and the motor-converter per-

fectly clean.

• In case of prolonged stopping, if there is no risk

of frost, it is better not to drain the pump.

• To avoid any locking of the shaft and the hydrau-

lic unit during the freezing period, drain the

pump by removing the plug (item 6) and lling

plug (item 5). Screw both plugs back in without

tightening them.

Replacement frequencies

NOTE: These are only recommendations, the

replacement frequency depends on the operat-

ing conditions of the unit , i.e.:

• Temperature, pressure and type of conveyed

uid for the mechanical seal.

• Load and ambient temperature for the motor and

the other components.

• Starting frequency: continuous or intermittent

running.

24H00 sliding

Defects

Active

relay

SBM

Rest

relay

Active

relay

SSM

Rest

relay

1 2 3 4 5

6

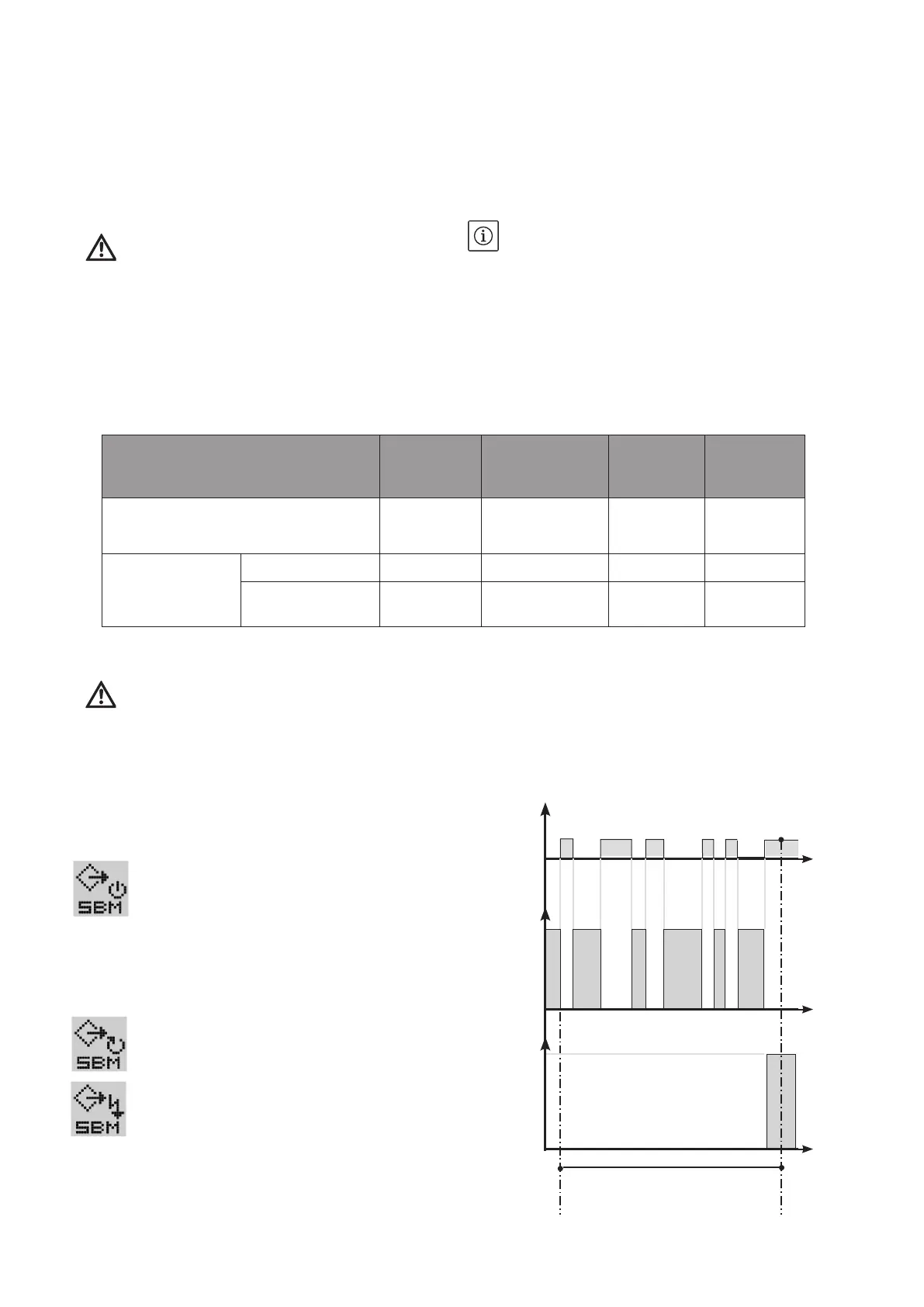

Parts or components subject to wear Mechanical seal

Pump and motor

bearings

Converter Motor winding

Indicative operating lifetime

10 000 h to

20 000 h

12 000 h to

50 000 h

≥ 15 000 h

Amb. maxi

40°C

25 000 h

Amb. maxi

40°C

Replacement

frequency

Continuous 1 to 2 years 1,5 to 5 years 1 to 3 years 3 years

15 hours per day

9 months per year

2 to 4 years 3 to 10 years - 6 years

Loading...

Loading...