EB 2517 EN 29

Installation

5.3 Control line, compensation

chamber and needle valve

5.3.1 Control line

The control line must be provided at the site

of installation, e.g. a

3

/

8

“ pipe for steam or

an8x1or6x1mmpipeforair/water.

Connect the control line to the upstream line

(p

1

) at least one meter away from the valve

inlet.

Weld the control line at the side in the mid-

dle of the pipe, inclining at a ratio of ap-

proximately1:10uptothecompensation

chamber.

5.3.2 Control line kit

A control line kit for tapping pressure directly

at the valve body is available as an accesso-

ries part from SAMSON.

5.3.3 Compensation chamber

Î RefertoTable8

A compensation chamber (18) is required

forliquidsabove150°Caswellasfor

steam. The mounting position of the compen-

sation chamber is indicated by an adhesive

label on the chamber itself as well as by an

arrow and the word "top" stamped on the

top of the chamber.

Thismountingpositionmustbeadheredto;

otherwisethesafefunctioningoftheexcess

pressure valve cannot be guaranteed.

Weld the line coming from the pressure tap-

ping point to the

3

/

8

“ pipe socket on the

chamber. Install the compensation chamber

at the highest point of the pipeline. Conse-

quently, the control line between compensa-

tion chamber and actuator must also be in-

stalled with a downward slope. In this case,

use a

3

/

8

“pipewithscrewttings.

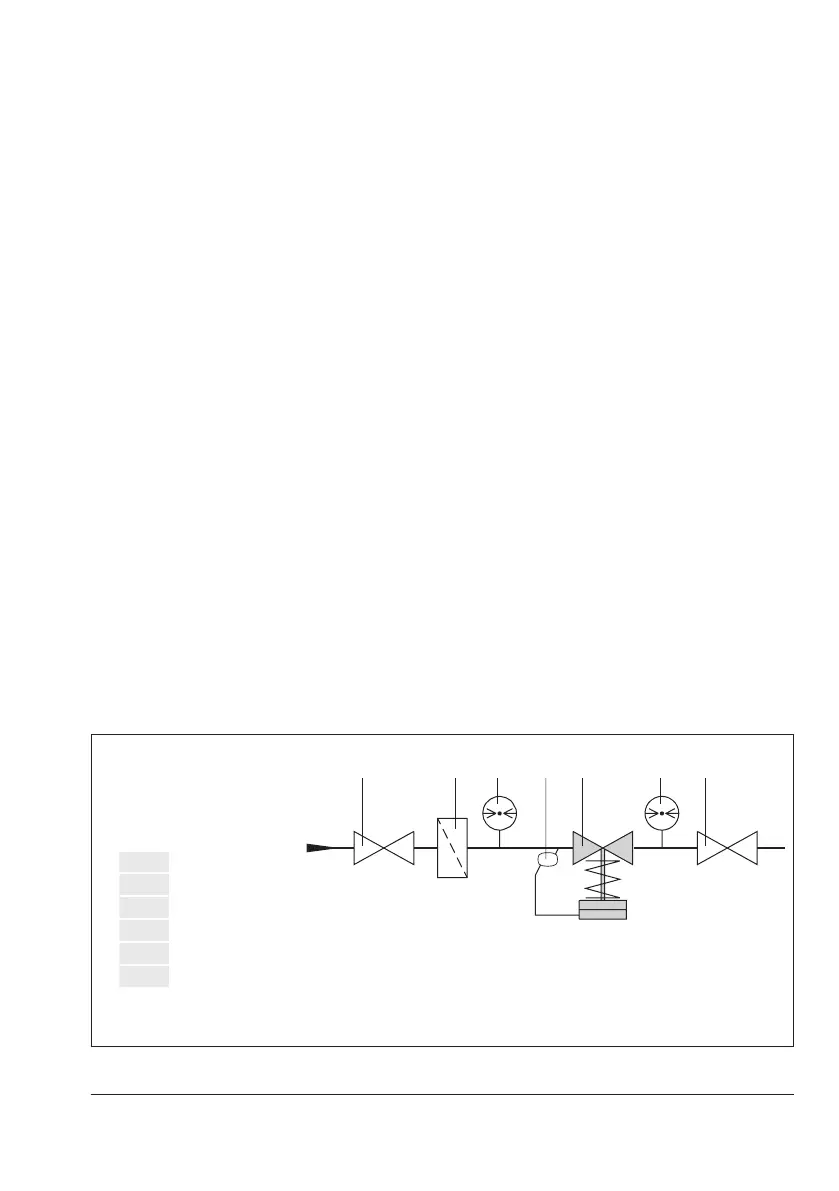

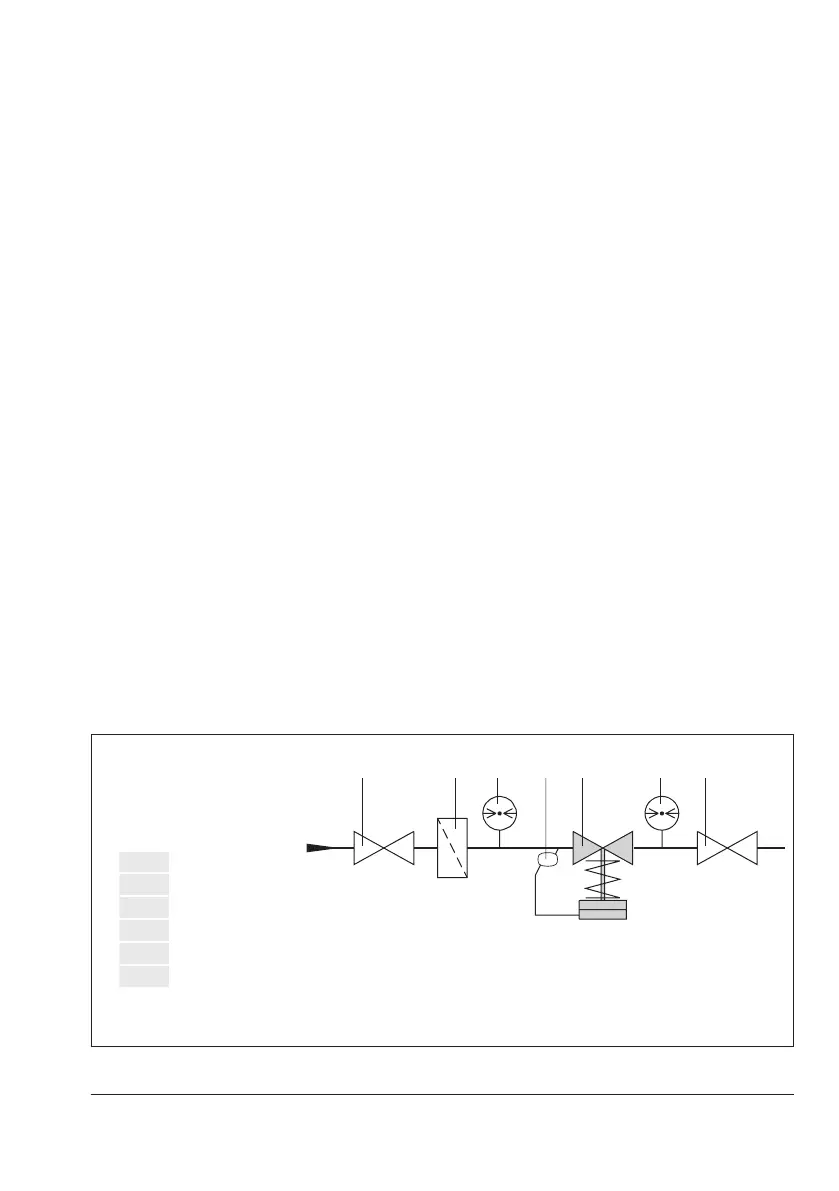

1 Shut-off valve

2 Strainer

3 Upstream pressure gauge

4 Excesspressurevalve

5 Downstream pressure gauge

18 Compensation chamber, e.g. for steam

Fig.7: Pressure control with Type41-73 (installation example)

Loading...

Loading...