INSTALLATION – GENERAL

PIPE FITTINGS

The connection points to the heating system are in 22mm copper pipe on 120, 150, 170 and 210 litre units. On units 250

litres and above the primary ow connection is 28mm, the ow connections to central heating (CH) zones 22mm and the

domestic hot water (DHW) return connection 22mm copper pipe. The use of appropriately sized COMPRESSION FITTINGS

is recommended when connecting to the PremierPlus SystemFit pipes. Solder ttings can be used, but extreme care must

be taken to ensure the plastic coating of the unit casing is not damaged by heat. Push t type ttings can be used for

connection to the copper pipes.

The inlet connection to the cold water combination valve is 22mm compression. The PremierPlus SystemFit outlet tting

is suitable for connection to 22mm o/dia pipe (compression nut and olive supplied). The outlet is also threaded 3/4” BSP

male parallel should threaded pipe connections be preferred.

COLD FEED

A 22mm cold water supply is recommended, however, if a 15mm (1/2”) supply exists which provides sufcient ow, this may

be used. More ow noise may be experienced from small bore pipes due to the increased water velocity through them.

A stopcock or servicing valve should be incorporated into the cold water supply to enable the PremierPlus SystemFit and its

associated controls to be isolated and serviced.

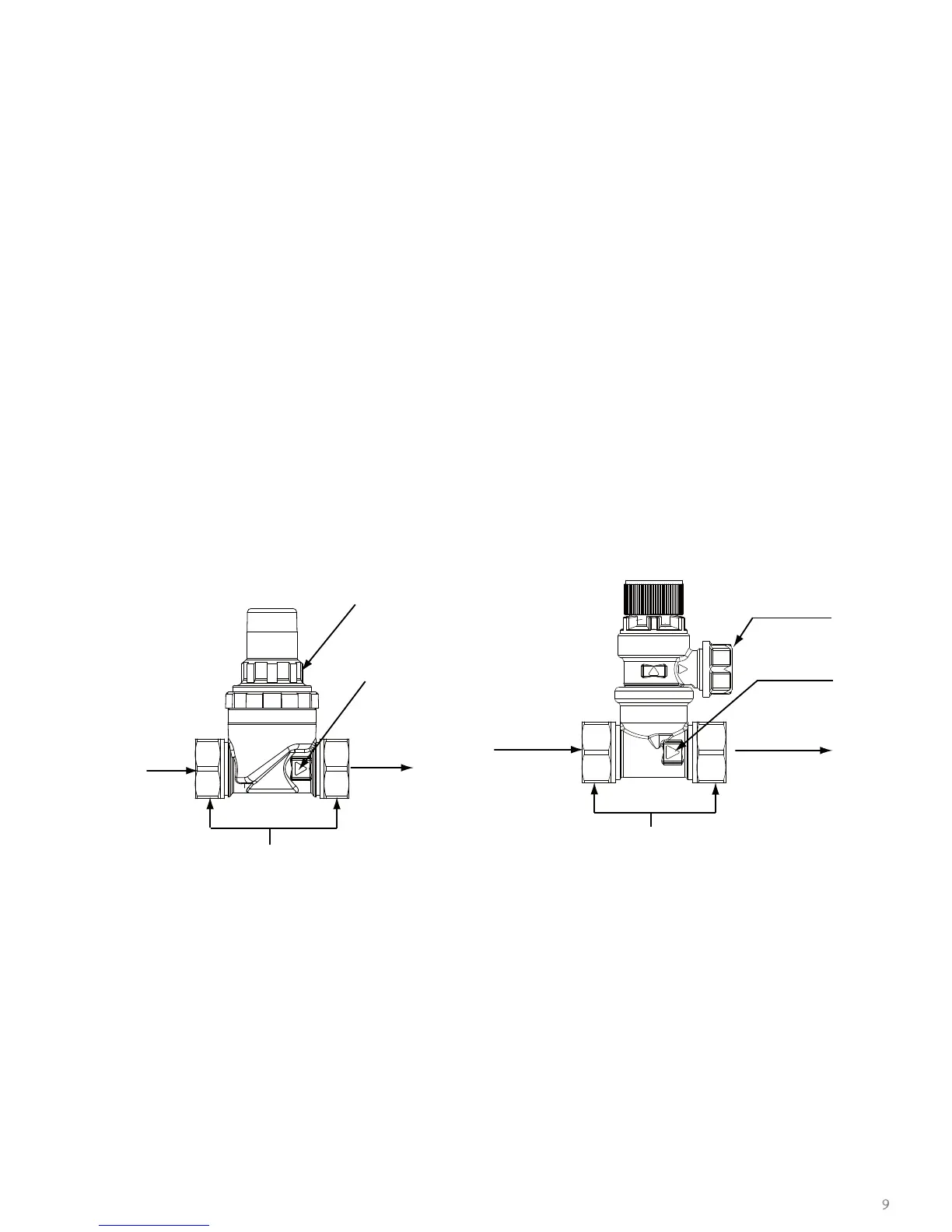

PRESSURE REDUCING VALVE (Fig 2 below)

The 3.5 bar pressure reducing valve can be connected anywhere on the cold water mains supply prior to the PremierPlus

SystemFit unit. There is no requirement to site it close to the unit, it can be located at a point where the mains supply

enters the premises if this is more convenient but you must install a non-return valve just after the reducing valve for ease

of maintenance.

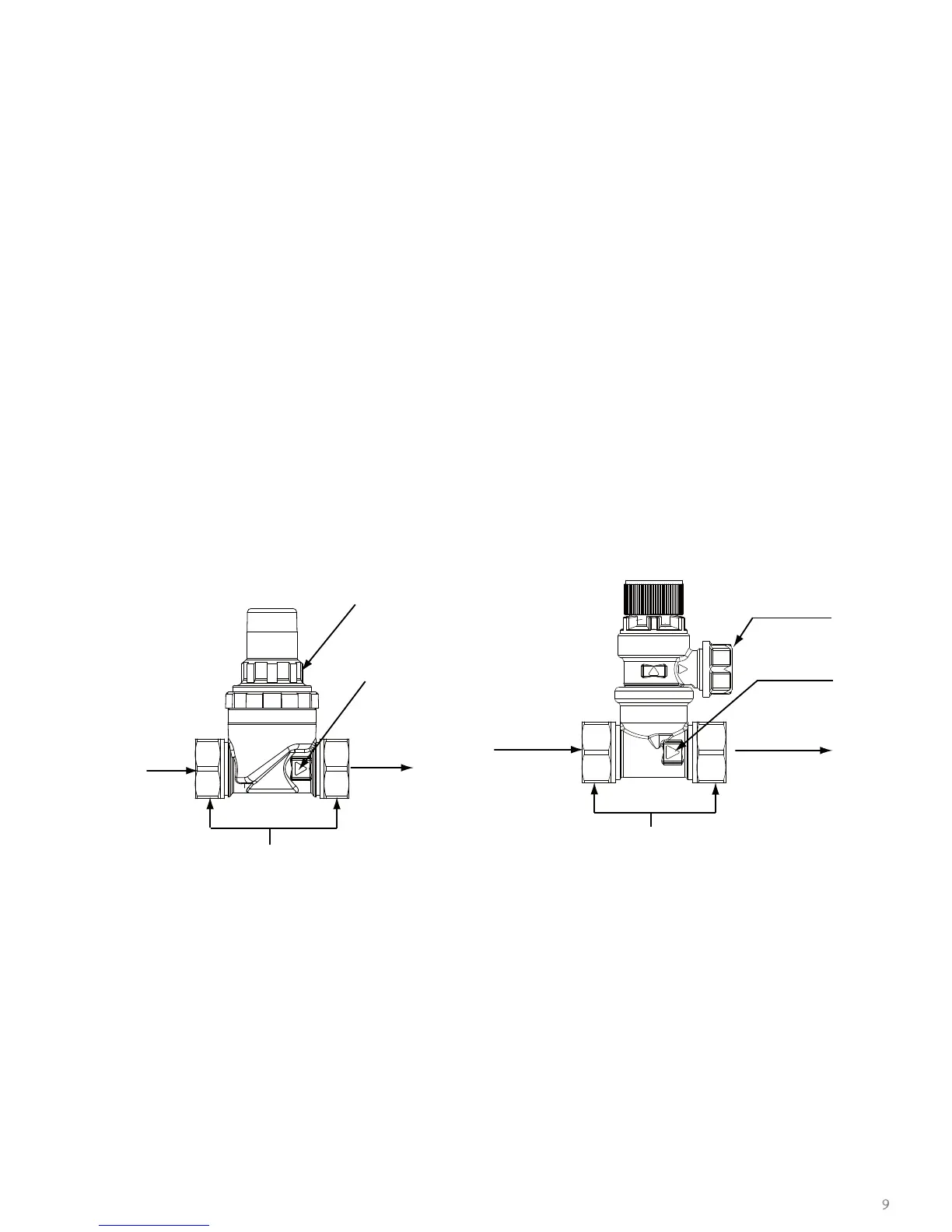

Fig 2 - Pressure reducing valve Fig 3 - Pressure relief valve (6 bar)

PRESSURE RELIEF VALVE (Fig 3 above)

Should a balanced pressure cold water supply be required to cold water outlets such as thermostatic shower mixer valves

or combination taps, the cold water balanced draw off connection should be taken from between the pressure reducing

valve and the pressure relief valve (see Fig 3 above). Branches to cold drinking water outlets should be taken directly from

the mains supply.

EXPANSION VESSEL

The expansion vessel accommodates expansion that results from heating the water inside the unit. The expansion vessel is

pre-charged at 3.5 bar. The expansion vessel must be connected between the expansion valve (see Fig. 3 above) and the

PremierPlus SystemFit cylinder. The location of the expansion vessel should allow access to recharge the pressure as and

when necessary, this can be done using a normal car foot pump. It is recommended that the expansion vessel is adequately

supported. An expansion vessel wall mounting bracket is supplied for this purpose and should be tted.

TUNDISH

The tundish must not be installed directly over any electrical device.

9

Outlet to cylinder

Loading...

Loading...