OPM 200 en-GB 64

©

Scania CV AB 2014, Sweden

Miscellaneous

Checking for leaks

1.

Start the engine.

2.

Check for oil, coolant, fuel, air or exhaust

leaks.

3.

Tighten or renew leaking connections.

Check the overflow holes which show

whether the O-rings between the cylinder

liners and crankcase are leaking.

4.

Check whether the drain hole on the coolant

pump is blocked. If there is a leak, renew the

seal in the pump or the complete coolant

pump.

If serious leakage occurs, contact your nearest

workshop.

Checking and adjusting the

valve clearance

Checking and adjusting valve clearances should

also be done one more time after the first 500

hours of operation. Then the normal interval will

follow (every 2,000 hours).

Valve clearances should be adjusted when the

engine is cold, at least 30 minutes after running.

Block the starting device when working on the

engine. If the engine starts unexpectedly, there is

a serious risk of injury.

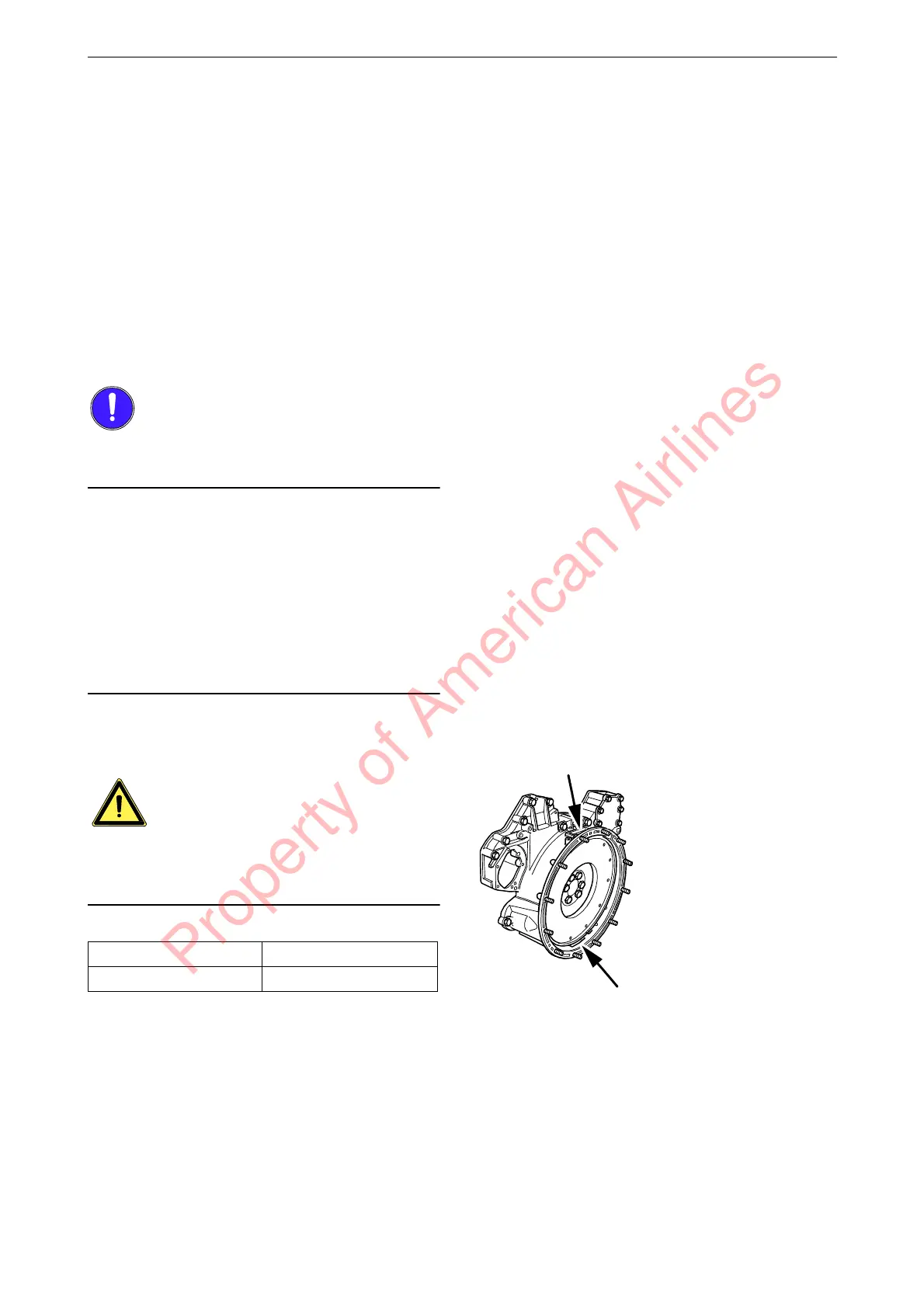

Readings can be taken from the flywheel through

openings in the flywheel housing either from

above or below depending on access when fit-

ting.

“TDC up” or ”"TDC down" is found on the fly-

wheel. Both openings are fitted with a blanking

piece on delivery.

Intake valve clearance 0.45 mm (0.018 in)

Exhaust valve clearance 0.70 mm (0.028 in)

310 343

Openings for taking readings on the flywheel hous-

ing.

Property of American Airlines

Loading...

Loading...