SCARAB M6 SWEEPER KIT

25 Operator’s Manual Amdt.1 - 03 November 2009

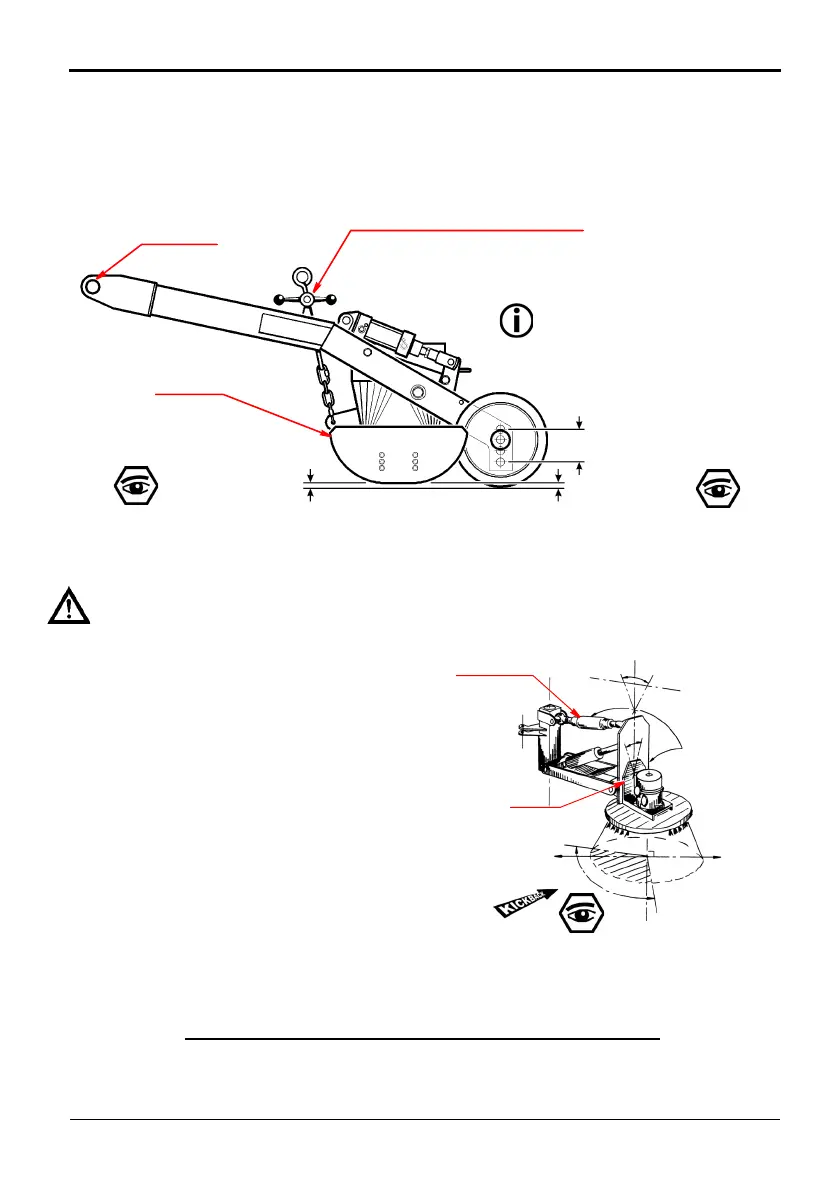

SUCTION NOZZLE CLEARANCES

Inspect the suction nozzle flaps to verify that they are in good condition

and do not show excessive wear. Adjust as necessary to achieve the

correct flap to ground clearances (Refer to Fig. 11).

Fig. 11 Suction Nozzle Clearance - Factory Set-up

FRONT FLAP = 20 mm

REAR FLAP = 30 mm

SIDE FLAP = 20 mm

Adjust FOR

Parallel Running

NOZZLE MINIMUM-HEIGHT ADJUSTER

Adjust For

Parallel Running

TOWPOINT

SKID PLATE

The height adjuster chain has been

superseded by a stainless steel lanyard

on later machines.

Side Flap is located at

opposite end of suction

nozzle from

NOTE:

These clearances are based on the

factory set-up. For some operating

conditions, it might be found that,

alternative clearances are preferred

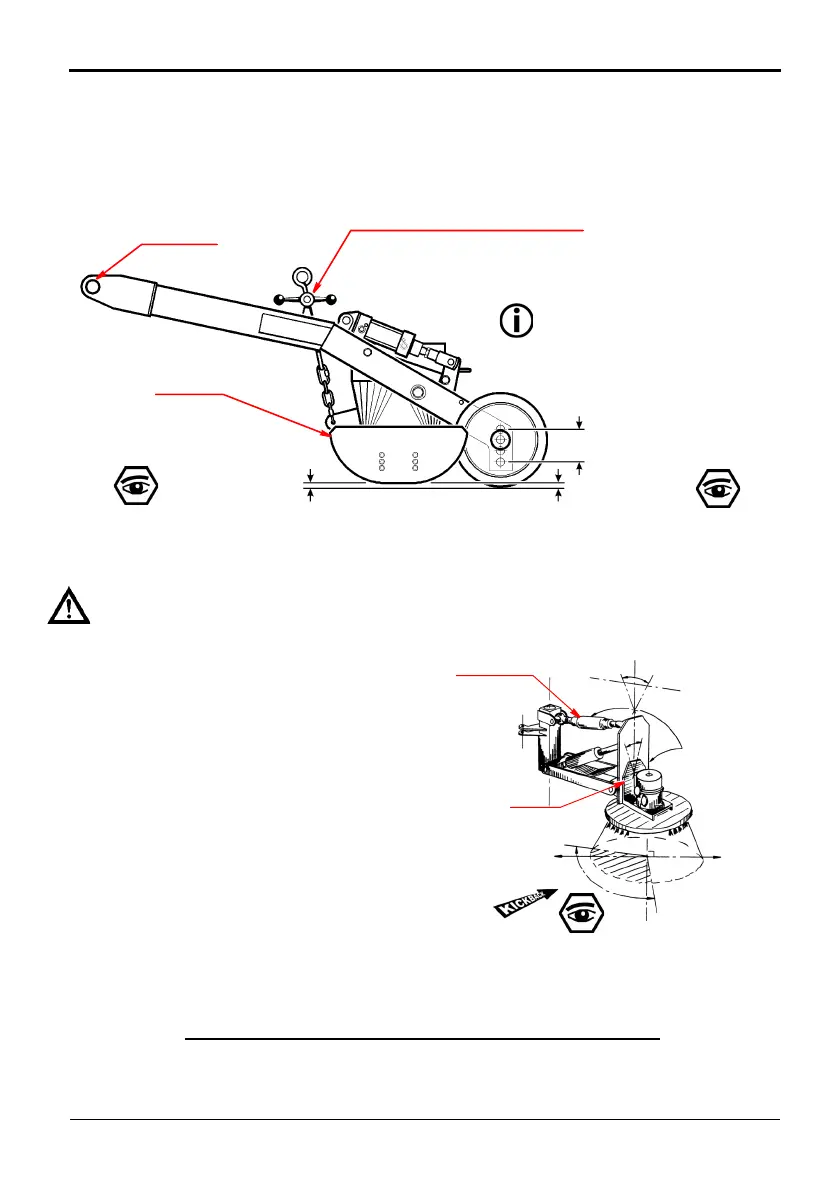

SIDE BRUSHES & SKIRTS

DO NOT ATTEMPT TO ALTER THE BRUSH SETTINGS WHILE THE BRUSH IS ROTATING.

Fig. 12 Brush Tilt Adjustment

TO FRONT

1

2

0

°

AREA IN CONTACT

WITH THE ROAD

BRUSH

ADJUSTMENT

POINTS

TOP LINK

MOTOR

PLATE

KI

C

K

B

A

C

K

An effective brush set-up ensures good

sweeping performance. The following

se

ttings produce excellent results in

most conditions. Experience will

determine if other settings are better

suited to specific conditions.

1. The brush s

hould be angled so

that it sweeps with its outer

leading edge. About 33% (120°)

of its circumference should be in

contact with the road surface.

2. The ski

rt adjacent to the brush,

which positions material for the

suction nozzle, should also be in

good condition and set so that

it just clears the ground.

Loading...

Loading...