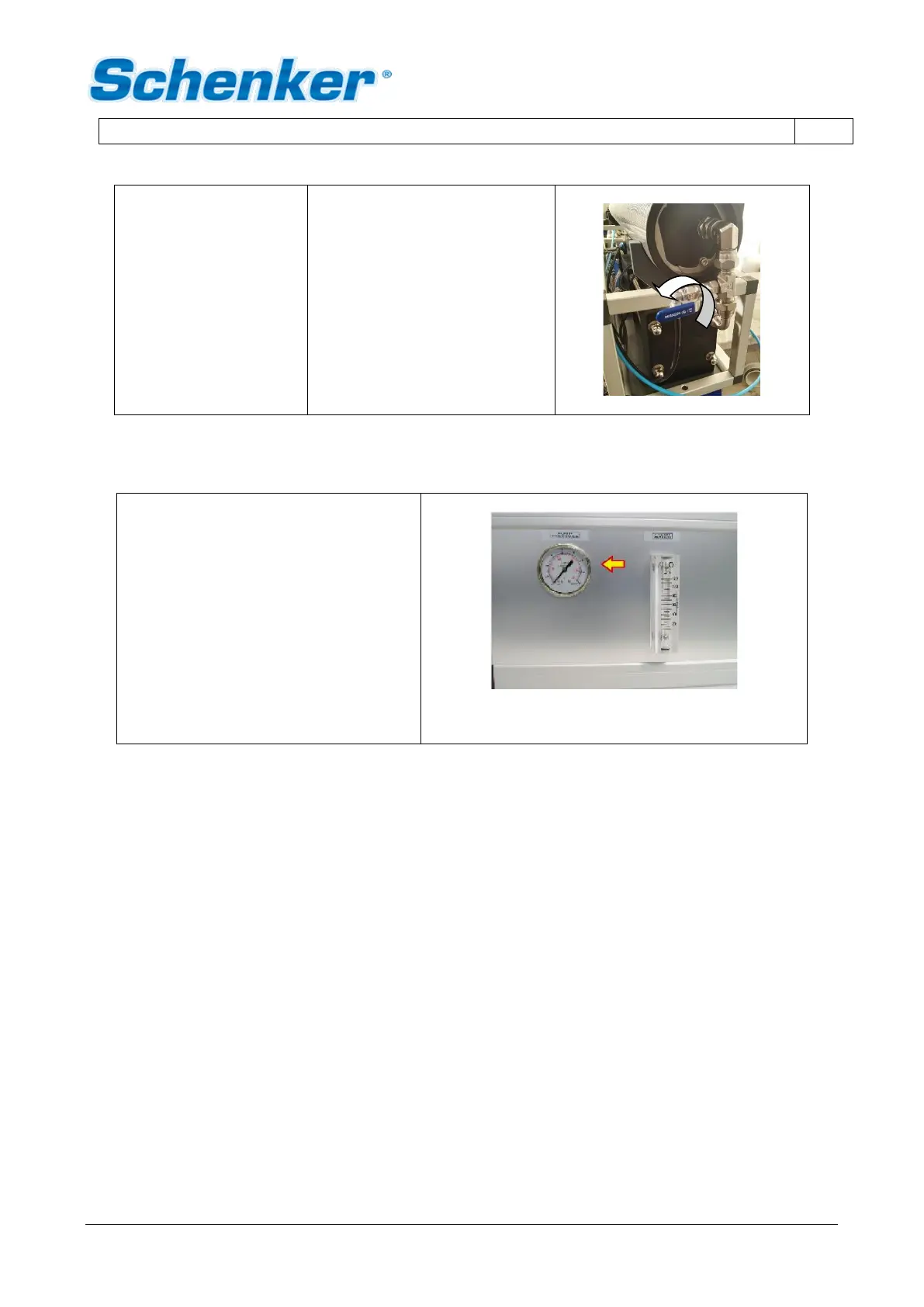

It is necessary to read the pressure on the

manometer located on the equipment front

panel in order to perform this verification.

The working pressure depends on many

factors such as water temperature, salinity

level of seawater, effective batteries

voltage, membranes cleaning degree,

typology of installation.

The pressure, in normal working

conditions, is approx. 8 – 10 Bars. There

is a small pressure drop, in the range of

0,4 bar, during the cycle.

If the average pressure exceeds the above ranges it is necessary to check the membranes cleaning degree.

It is necessary to perform the shutdown procedure if the membranes result dirty. If cleaning also results

insufficient it could be necessary to perform an alkaline washing using the chemical product SCHENKER

CLEANING 2 (SC2). It is recommended to contact a Schenker certified service centre.

6.3 Check for leaks

It is necessary to perform this verification at every plant start-up and however often, since possible leaks due

to accidental causes (hose bursting, hose clamp loosening, equipment failure, etc.) may occur, even plentiful,

with the consequence of possible damages.

6.4 Check for membranes replacement

The reverse osmosis membranes have a 7 years average working life. It is recommended therefore, after 5

years of operation, to verify the possible necessity of substitution and however to perform the substitution after

7 years.

6.5 Shutdown procedure

It is necessary to perform the shutdown procedure before standstills longer than 3 months, for instance before

the winter laying up.

The purpose of the shutdown is to flush the system from possible organic and inorganic sediments, and inhibit

the growth of bacteria that could reduce the reverse osmosis membranes efficiency.

Loading...

Loading...