english 21

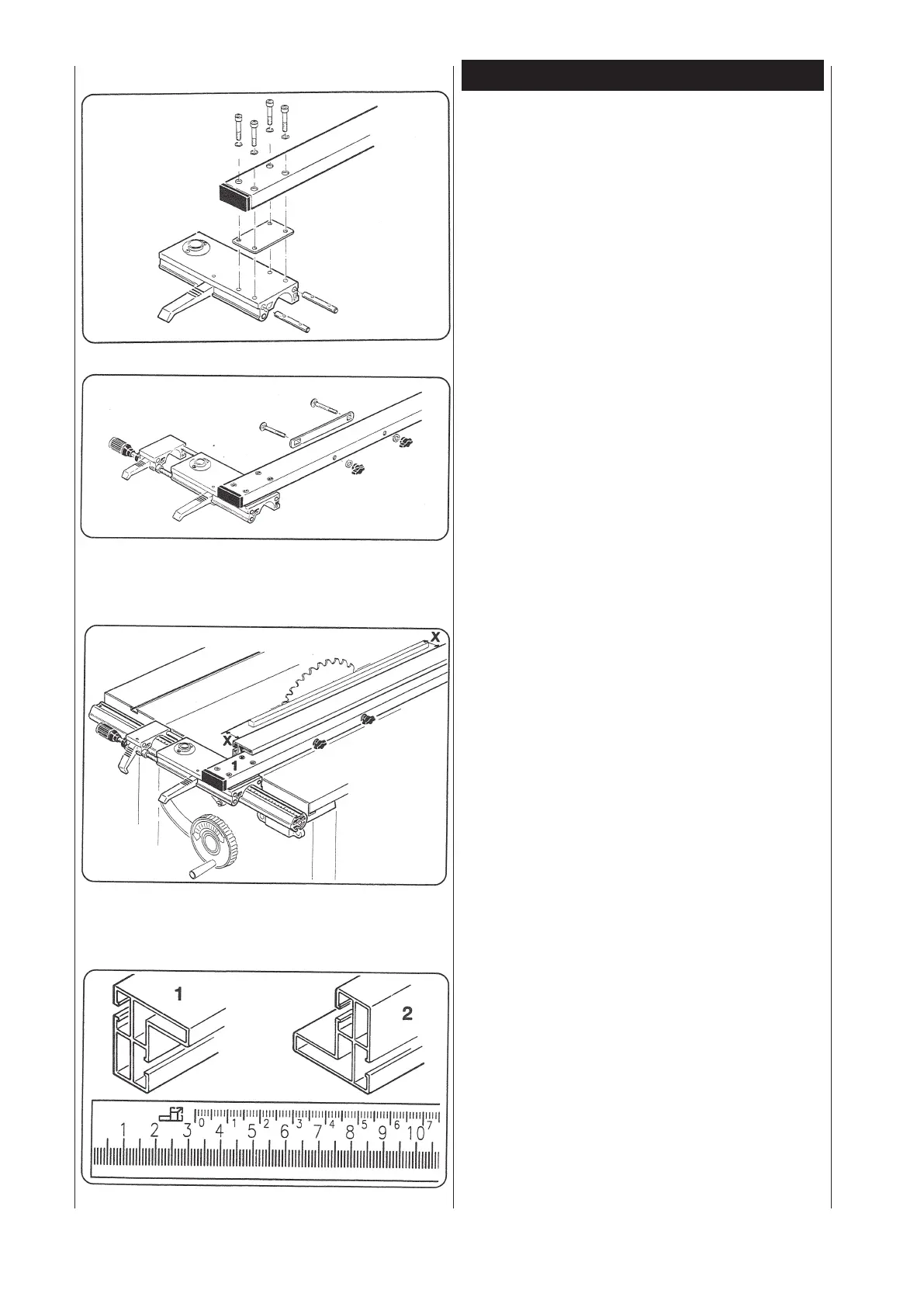

Fig."A"

Fig."B"

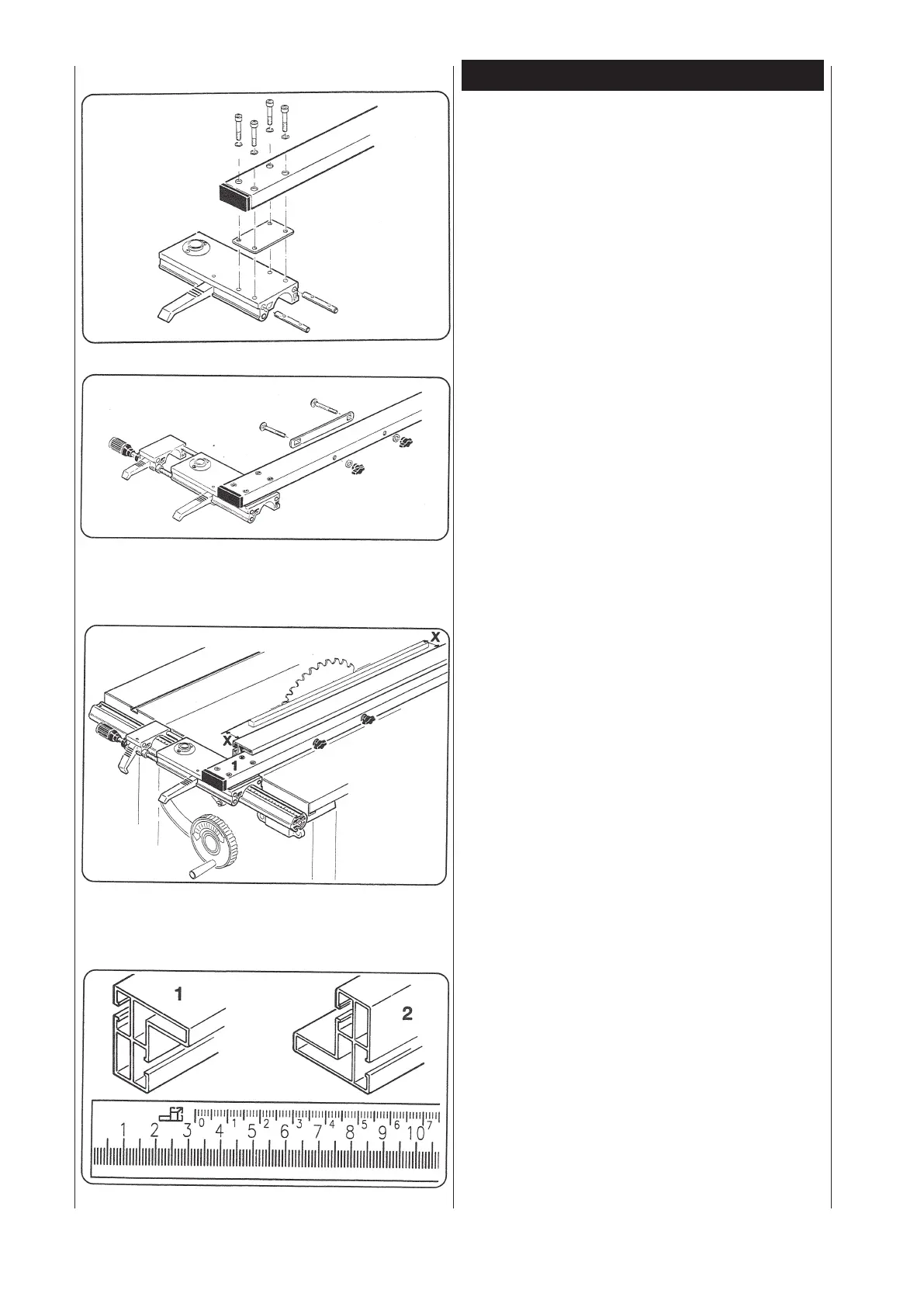

Fig."F"

Fig."G"

Mounting

All assembly and retrofitting work may only be performed when the

mains plug has been disconnected.

Your scheppach circular sawbench is not completely assembled for

packaging reasons.

Assembly tools

Thefollowingareincludedinthescopeofdelivery:

1openendspanner 19mmwidthacrossats

1openendspanner 30mmwidthacrossats

1allenkey 5mmwidthacrossats

1allenkey 6mmwidthacrossats

1allenkey 4mmwidthacrossats

Parallel fence Fig. "A"

Screwthefencesection,inbetweenplateandguidingslide

together.Forthispurpose,insertthethreadedboltsinthe

guiding slide.

4 intermediate bushes

4 cheese head screws M 6 x 40

Fig. "B"

Attachtheintermediateplatetothefencesection.

- Do not tighten -

2 cheese head screws M 6 x 75

2 washers 6

2 wing nuts M 6

Parallel fence adjustment

Fig. "F"

•Opentheextenderleverontheslidingtable(pullupwarts)

and put it condescendingly on the guide tube

For precise adjustment of the parallel fence in relation to the

circularsawblade,releasethefourcheeseheadscrews(1),

andclamptheguideslideatadistanceofapprox.100 mm

fromtheblade.Placeastraightslatofapprox.600 mm length

againsttheblade.Alignthefenceparallelwiththesawblade

by repeated measurement (X) andreadjustment.Retightenthe

cheese head screws (1)

Important!

For cutting widths below 120 mm always use a push stick.

Stop rail

Fig. "G"

Position 1:

For working with raised stop bar surface. The displayed cut

width is on the black display scale.

Position 2;

For working with lowered stop bar sur- face.

Thedisplayedcutwidthisonthebluedisplayscale.(Lower

stopbarsurfacesymbol)

Loading...

Loading...