Operating Instructions

VACUMASTER

Chapter 6

Troubleshooting

J. Schmalz GmbH

Aacher Straße 29

D - 72293 Glatten

Tel +49 +7443 / 2403 - 0

Fax +49 +7443 / 2403 - 259

http://www.schmalz.de

e-mail: schmalz@schmalz.de

30.30.01.00185 Status 03.2013 / Index 00 Page 23 / 28

This unit should only be installed and maintained by qualified specialist per-

sonnel (mechanics and electricians). Work on electrical equipment may only

be carried out by qualified electricians.

After repair and maintenance work, always check safety equipment as set out

in the "Safety" manual.

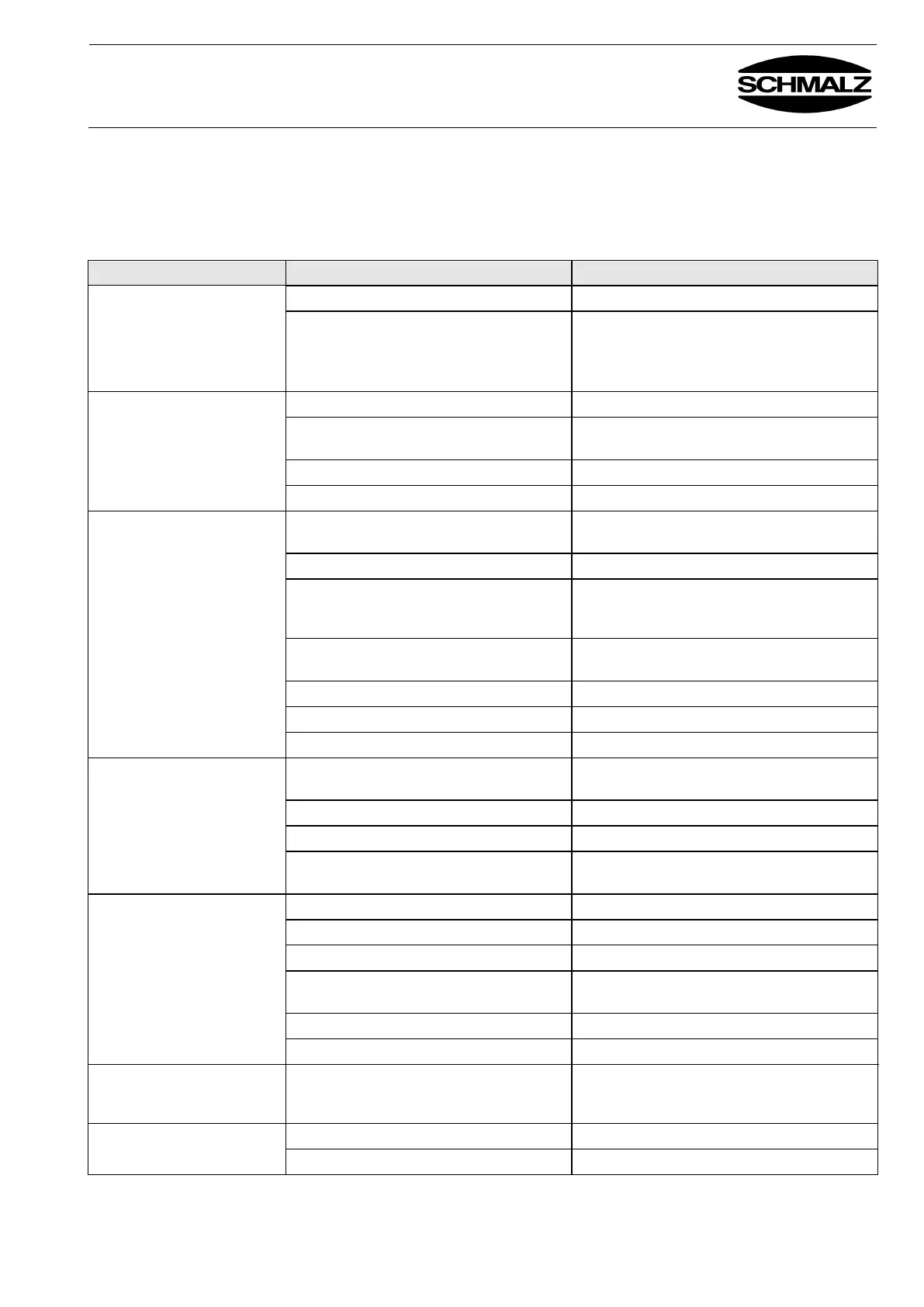

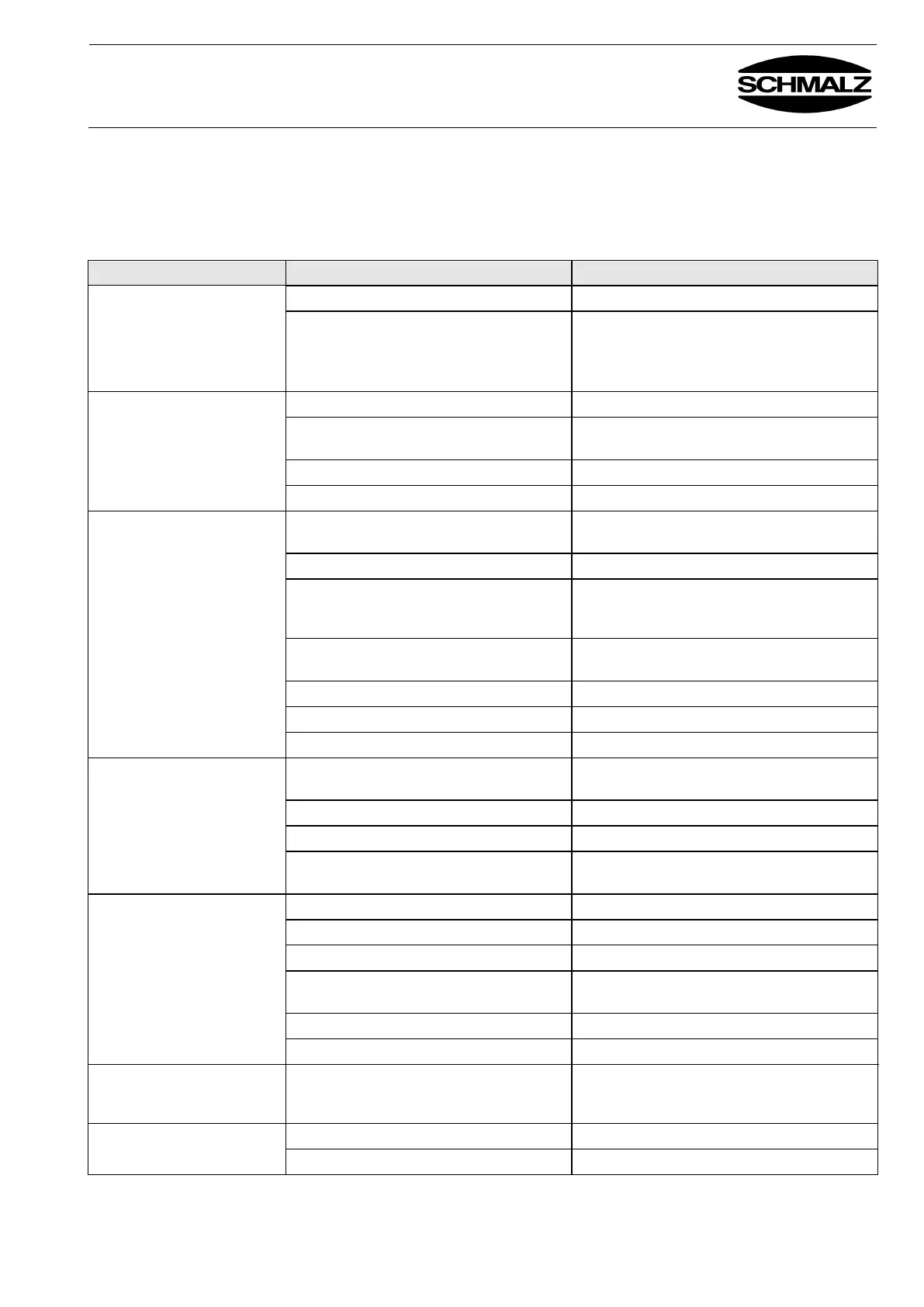

Vacuum generation is not

operational

Check supply system or pressure reducer

Pressure in compressed air supply system

too low

Adjust pressure to 6 – 7 bar

Vacuum of -0.6 bar or -

0.2 bar not reached

Sealing lip of the suction plate is damaged

Workpiece has cracks, notches or is too

porous

This lifting device cannot handle the

workpiece

Leaking hose / screw connections

Replace / seal components

Vacuum generator

functioning but working part

not being picked up

Manual sliding valve on the operating

lever is in the "Release" position

Move the manual sliding valve on operating

lever into the "Pick up load" position

Manual sliding valve fault

Not all suction plates cover the workpiece

(leaking air is being sucked in)

Position the lifting device on the workpiece

such that all suction plates cover the work-

piece completely

Valve on suction plates not covered by the

workpiece is open

Switch off the suction plate in question using

the valve on the suction plate

Clean or replace cartridge

Leaking hose / screw connections

Replace / seal components

Cracks, gaps in workpiece or porous

workpiece

This lifting device cannot handle the

workpiece

Hose fault / leaking screw connections

Vacuum switch adjusted / fault

See the operating manual "Vacuum switch"

or contact customer service

Elect. connection reversed, fault

Check connection, correct if necessary

Motor protection switch triggered

Voltage on two phases only

Current consumption increased

Check motor for fault – overheated? (allow to

cool), clean vacuum filter

Check pump / call after-sales service team

Vacuum generator

functioning but working part

not being picked up

Pump rotation direction reversed

Check connection, correct if necessary

Motor of rotating or turning

device does not work

Have linear actuator repaired or replaced

Loading...

Loading...