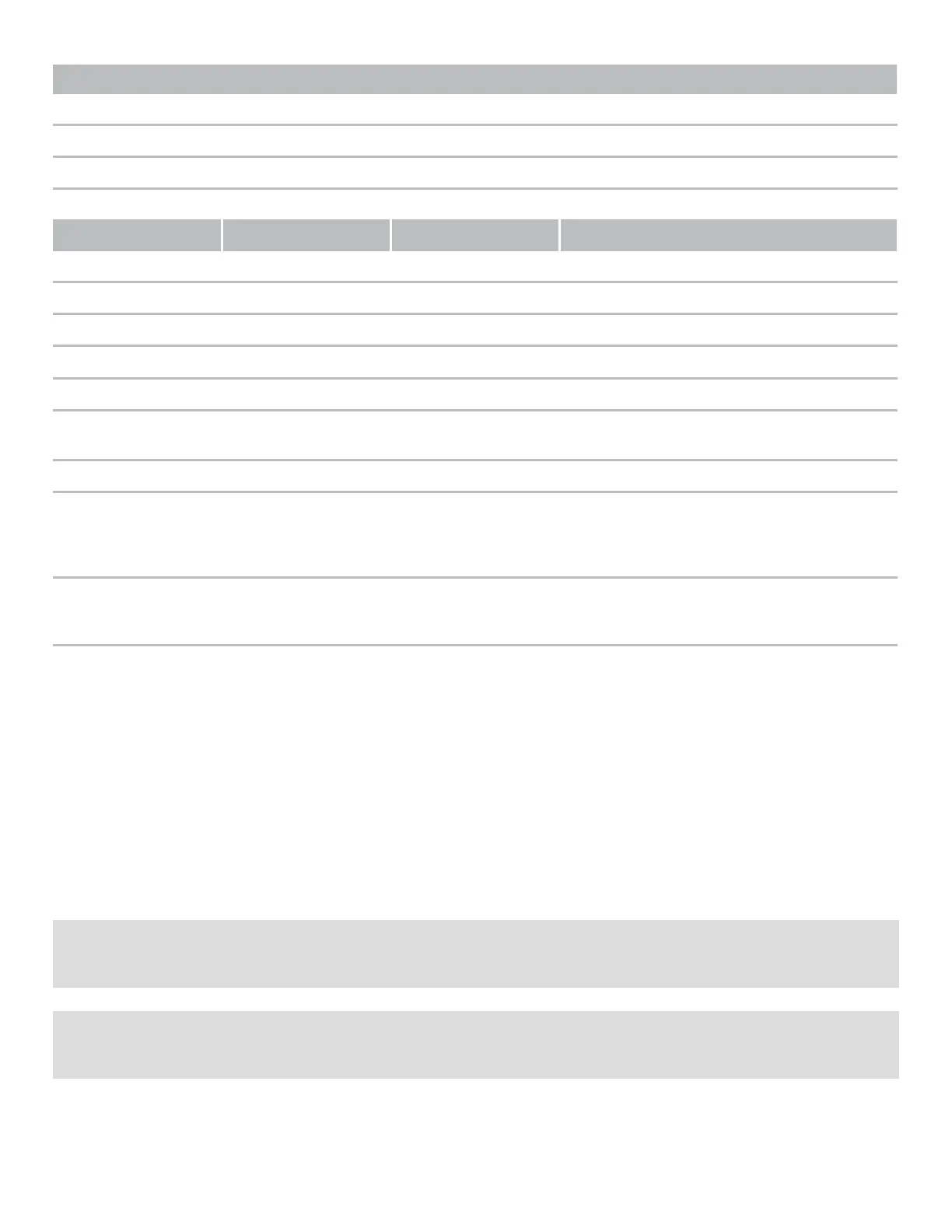

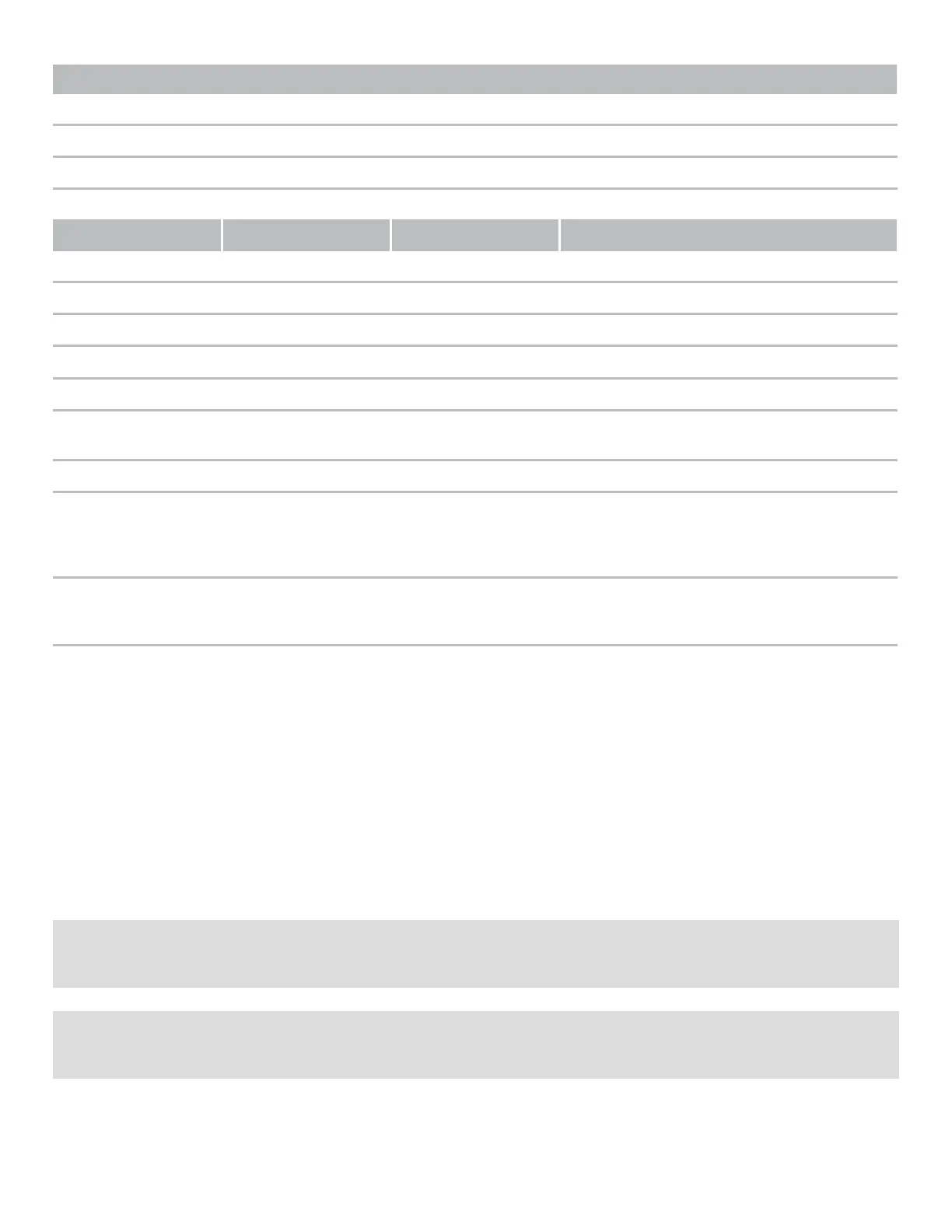

Table 3: Tabular overview of status signals, warnings or error messages(The described condition is reached, when Bit = 1)

Communication directions: Request byte: from the PLC to the local safety sensor

Response byte: from the local safety sensor to the PLC

Warning/error byte: from the local safety sensor to the PLC

Bit n° Request byte Response byte Diagnostic

Error warning Error messages

Bit 0: --- Safety output activated Error output Y1 Error output Y1

Bit 1: --- Actuator detected Error output Y2 Error output Y2

Bit 2: --- --- Cross-wire Y1/Y2 Cross-wire Y1/Y2

Bit 3: --- --- Temperature too high Temperature too high

Bit 4: --- Input condition X1 and X2 --- Incorrect or defective

actuator

Bit 5: --- Actuated in limit area Internal device error Internal device error

Bit 6: --- Error warning Communication error

between the field bus

Gateway and the safety

switchgear

---

Bit 7: Error reset Error

(enabling path switched

off)

--- ---

8 Set-up and maintenance

The safety function of the safety components must be tested. In the case of correct installation and adequate use, the

safety switchgear features maintenance-free functionality. A regular visual inspection and functional test, including the

following steps, is recommended:

1. Check fixation of the safety switch and the actuator.

2. Fitting and integrity of the cable connections.

3. The system is free of dirt and soiling (in particular metal chips).

2

Adequate measures must be taken to ensure protection against tampering either to prevent tampering of the safety guard, for

instance by means of replacement actuators.

2

Damaged or defective components must be replaced.

Loading...

Loading...