SERVICE TRAINING

Service Manual

11

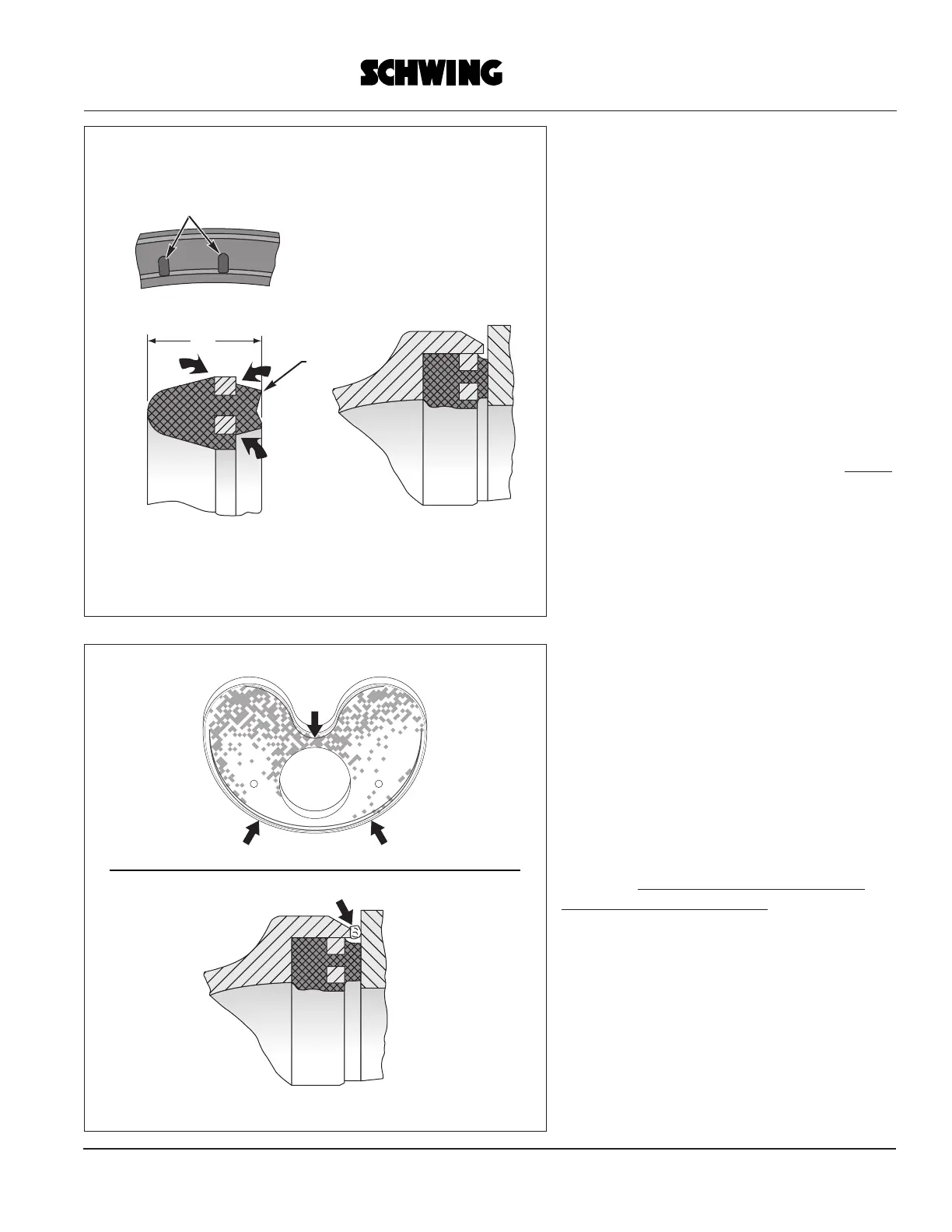

Rock Valve

(2) - Pressure Relief Grooves

(1) - Lip

Spring compressed

(Installed)

Spring uncompressed

d

mm

M

Figure 1

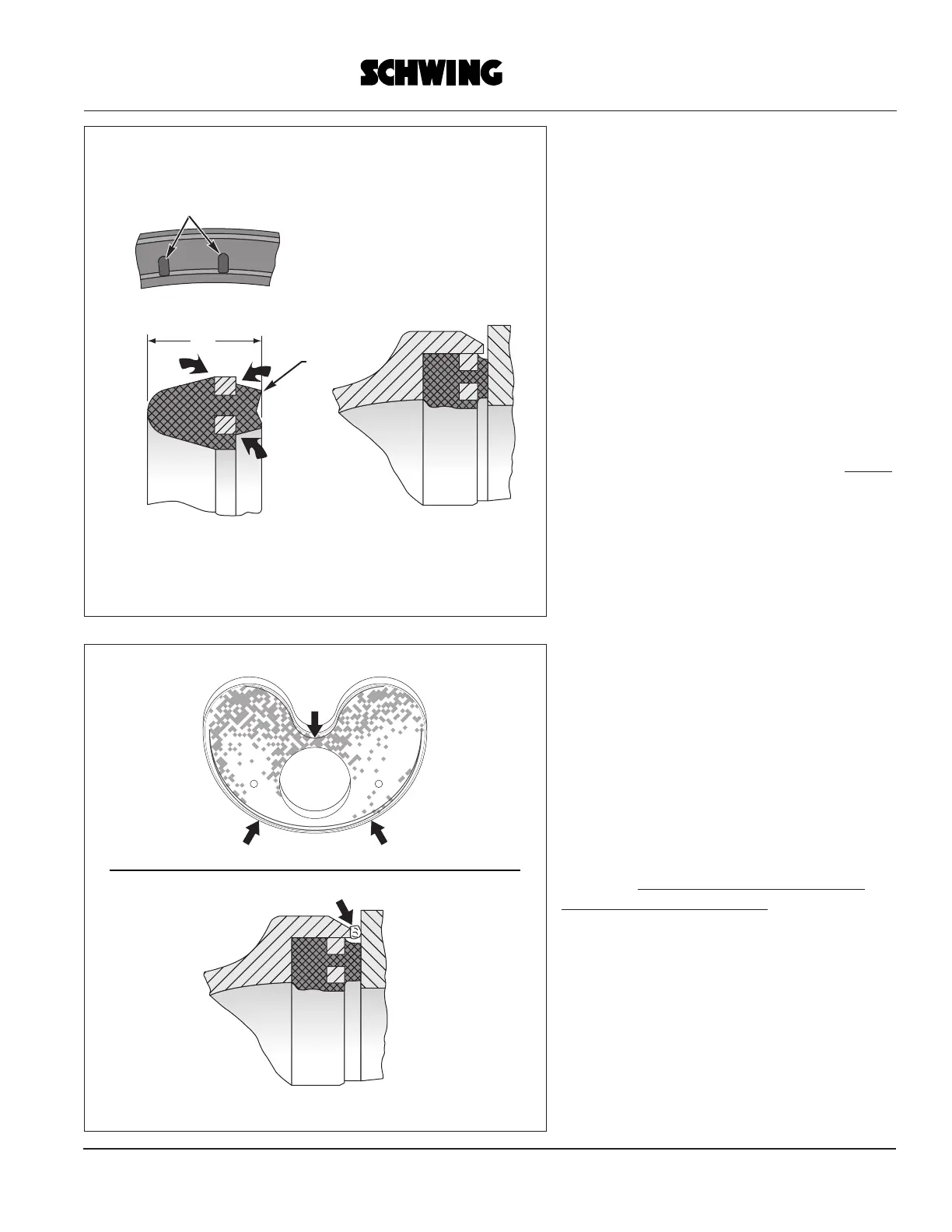

Figure 3

Aggregate Particle

Figure 2

Determining Wear on Kidney

Seal and Kidney Plate

Replace the kidney seal if any of the following

conditions exist:

• The seal is swollen due to use of aggressive

or harsh cleaning agents. (See Service bulle-

tin G-113-84, dated July 18, 1984)

• A considerable formation of cracks are

found in the areas marked by arrows. (fig. 1)

This problem is very rare.

• Lip (Item 1, fig. 1) is completely worn to the

point that the pressure relief grooves (Items

2, fig. 1) are no longer recognizable.

• The distance indicated by “M” of the Kidney

Seal (when force is relieved) does not e

xceed

30mm (1 3/16”).

Replace the Housing Lining-Oulet Side (Kidney

Plate) only if scores deeper than 2.5mm are

found, in the area that contacts the Kidney Seal.

You can measure this by placing a steel ruler

across the kidney Plate in several places, and

using a depth gauge to determine the gap.

NOTE: Outside of the area that contacts the

Kidney Seal, you may detect scores that are

due to aggregate particles stuck between the

Rock Valve and the Kidney Plate. (See fig. 2

and fig. 3) These scor

es will not affect the

operation of thr Rock Valve.

Under no circumstances should you allow the

Kidney Seal to be run with a dry hopper. This

will destroy the Kidney Seal, and is the primary

cause of premature wear encountered at the out-

let side of the Rock Valve.

If you will be repairing the Rock, or trouble-

shooting a problem, always fill the hopper with

water to the top of the Rock Valve before switch-

ing.

Loading...

Loading...