Operation and Maintenance Manual SC9DF Electronically Controlled Diesel Engine for Agricultural Equipment

46

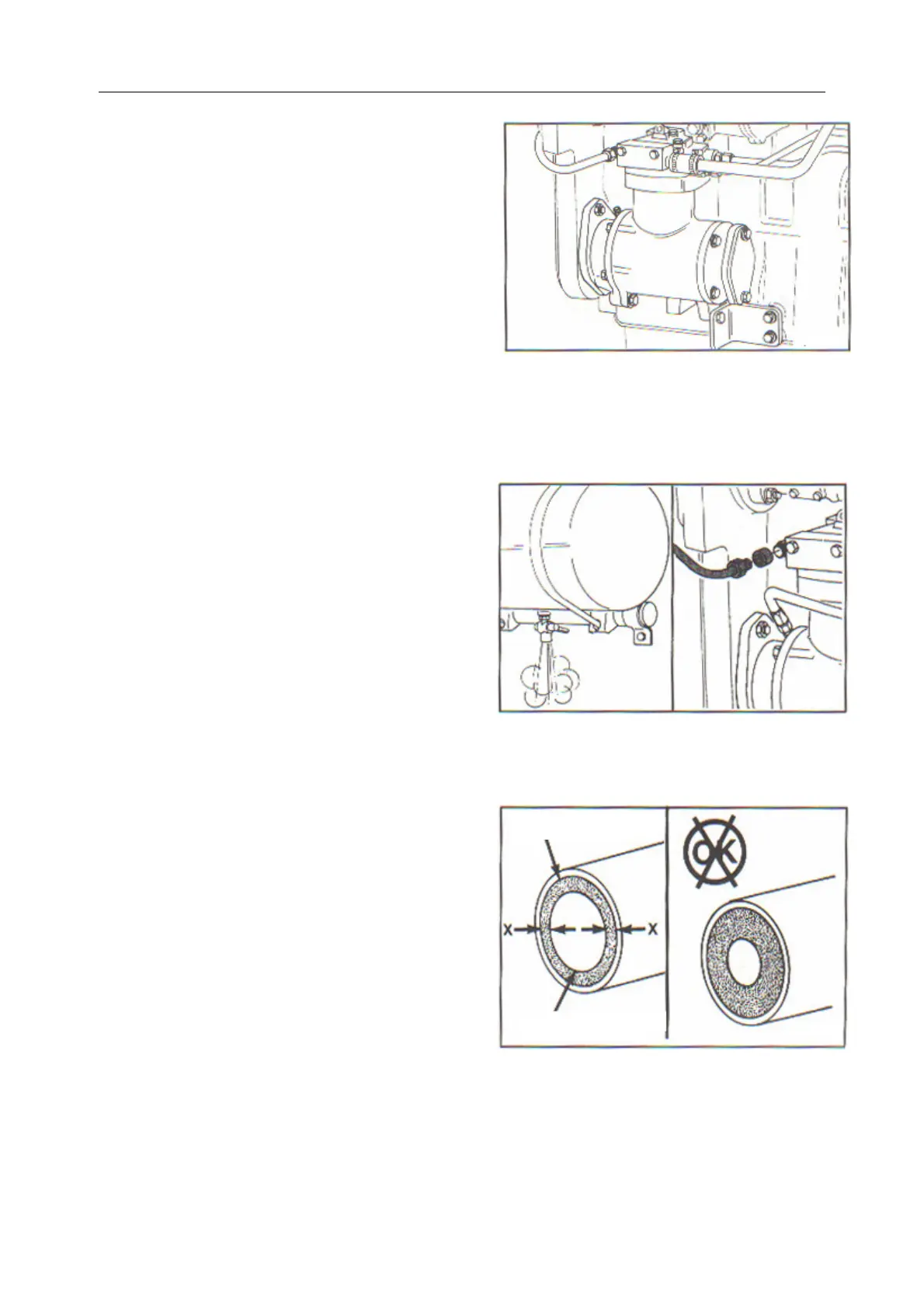

4.7.3 Check air compressor

An air compressor adopts a small amount of oil to lubricate its

piston ring and moving parts. Cement or carbon deposit will be

generated in the oil when the air compressor has been

running under the normal working temperature for a certain

time. Therefore, the piston ring will lose sealing function due

to high working temperature and pressure if the following

checks are implemented.

Check the air outlet pipe of the air compressor

Discharge the compressed air in the brake air reservoir.

Remove the air outlet pipe from the air compressor.

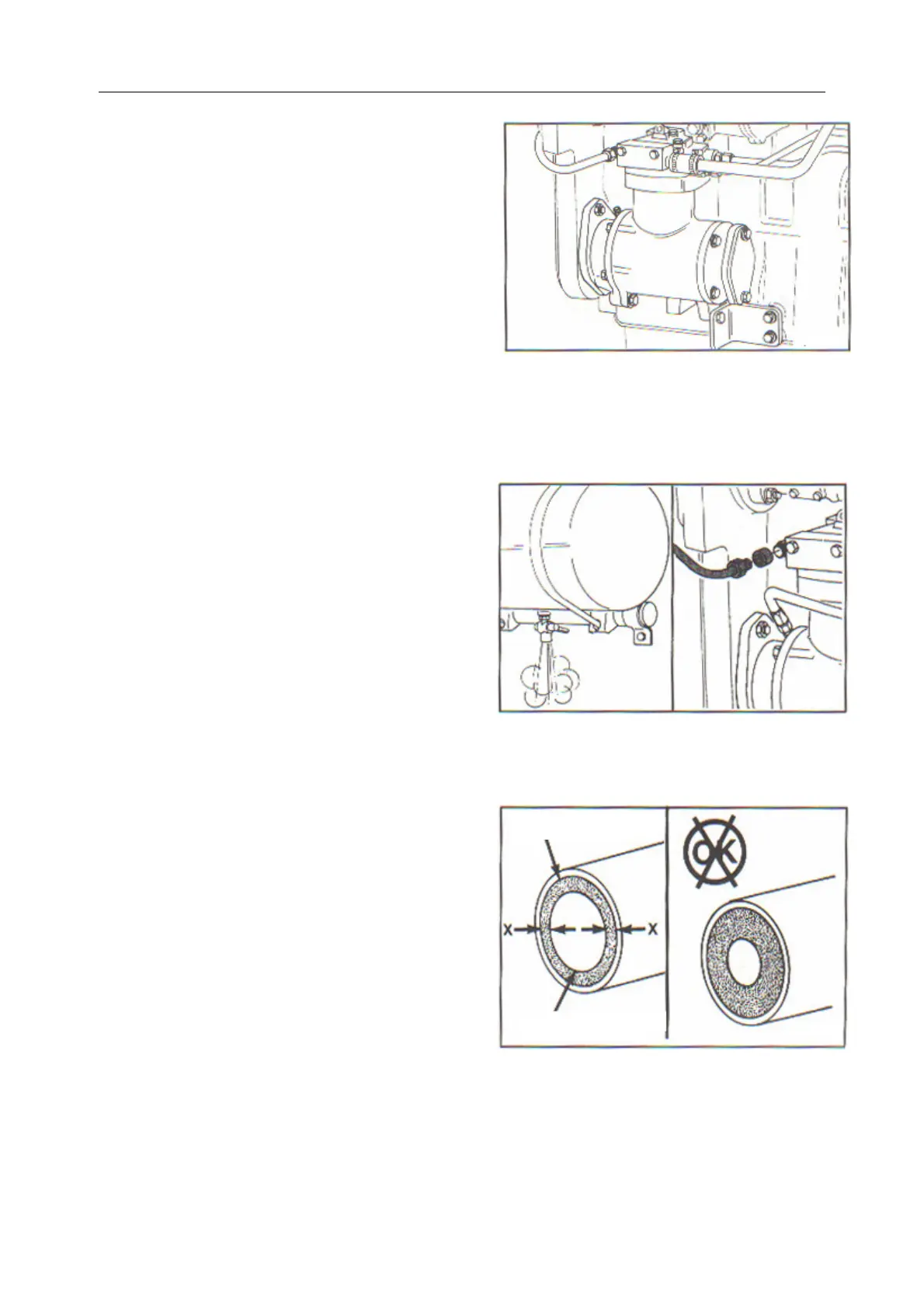

Measure the total thickness of carbon deposit inside the air

outlet pipe of the air compressor. If the total thickness (×+×)

exceeds 2 mm, clean and check air compressor cylinder head,

valve assembly and air outlet pipe. Replace them if

necessary.

If the total thickness exceeds the specified limit, check along

the air outlet pipe adapter between the air compressor pump

and the compressed air reservoir until the carbon deposit

thickness is less than the specified limit. Clean or replace the pipe adapter or connector where total thickness of the

carbon deposit exceeds the specified limit.

Inner diameter of

exhaust pipe

Inner diameter of

carbon deposit

Loading...

Loading...