Operation & Maintenance Manual──LG958L/LG959 Wheel Loader

97

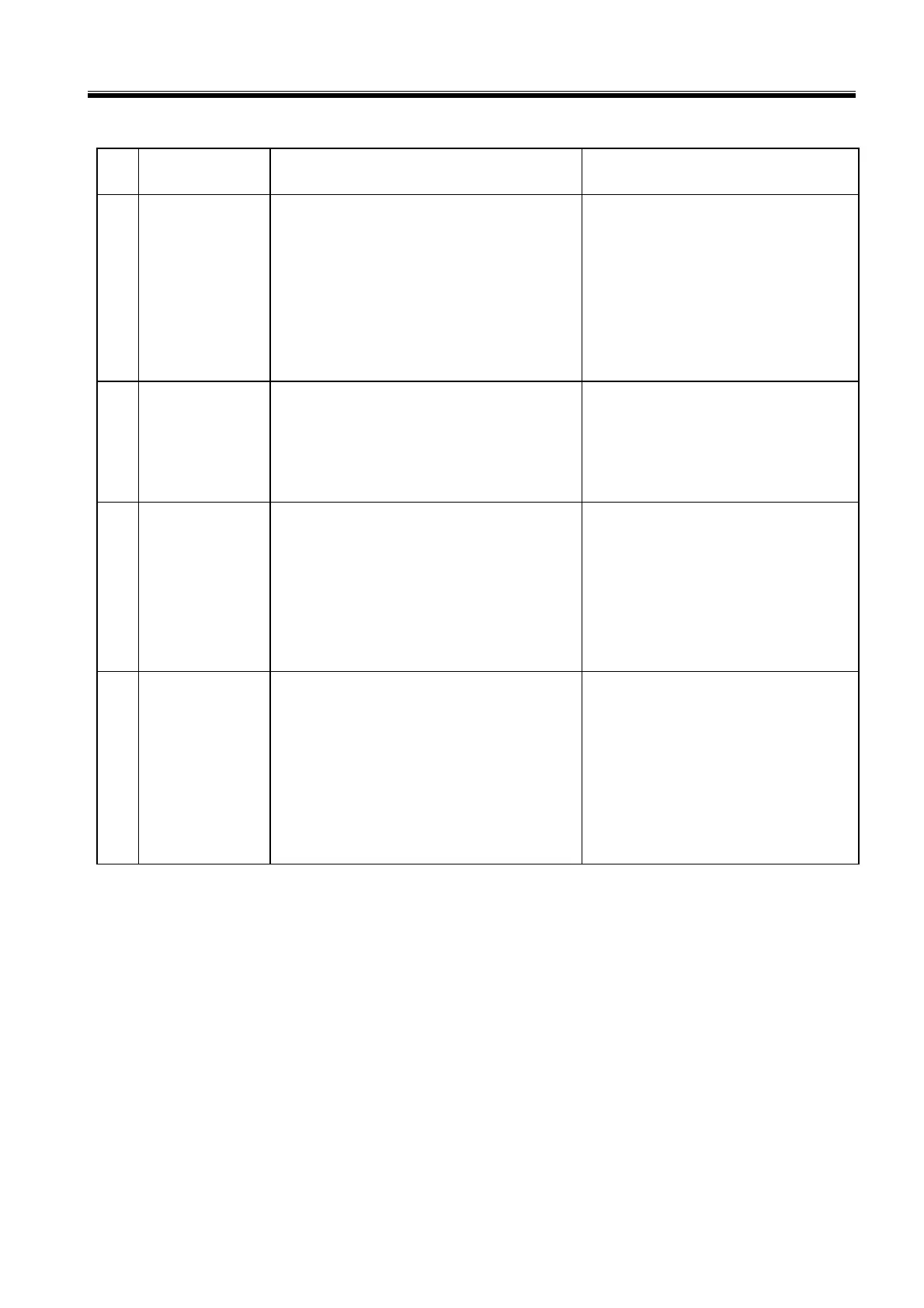

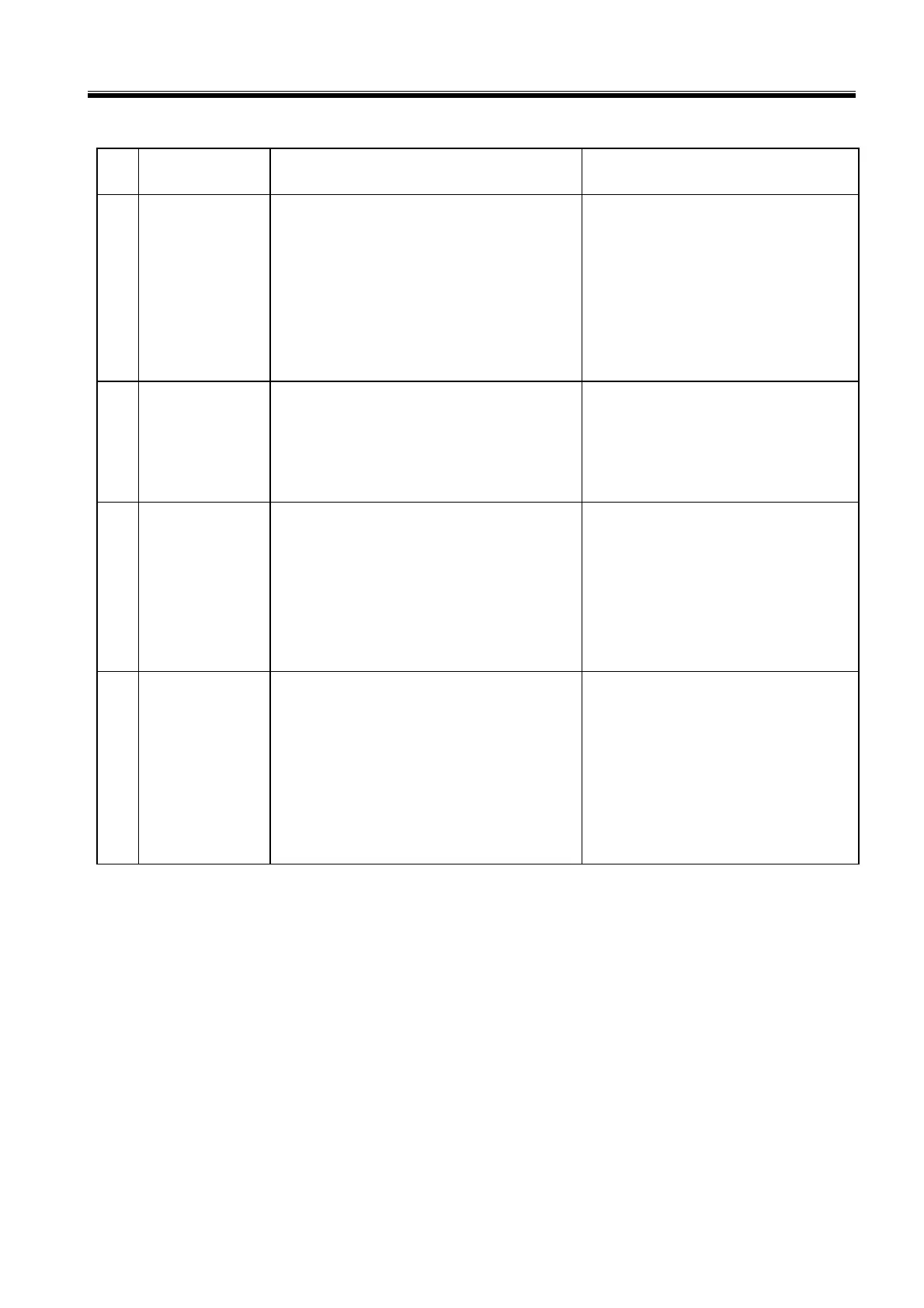

3.8.3 Brake System

No. Problems Possible Causes Remedy

1

Insufficient

brake force

1 Oil leakage of pliers pump

2 Air in brake hydraulic lines

3 Low brake air pressure

4 Over worn leather cup of booster pump

5 Oil leakage from hub to brake plates

6 Worn brake plates

1 Change rectangular sealing ring of

pump

2 Bleed the air out

3 Check the sealing performance of

air compressor, control valve,

storage tank and lines.

4 Change the leather cup

5 Check or replace the seal of hub

6 Change brake plates

2

Failure to release

the brake

normally

1 Wrong position of brake valve spool,

locked piston rod, damaged or faulty

reset spring

2 Improper operation of booster

3 Pliers piston can’t reset

1 Refer to problem 2

2 Check the booster pump

3 Check or replace the rectangular

seal ring

3

Pressure in air

storage tank

drops quickly

after shutting

down (pressure

drop is over 0.1

MPa in 30 min)

1 Inlet valve of foot brake valve is

clogged by dirt as damaged

2 Loose pipe fitting or broken pipes

3 Poor sealing performance of check valve

in combination valve of oil-water

separator

1 Brake continuously several times

to blow the dirt off or change valve

2 Tighten the pipe fitting or change

brake pipes

3 Find out the reasons for sealing

failure and change parts if

necessary

4

Slow rise of

pressure reading

in the brake

gauge

1 Loose pipe fitting

2 Abnormal work of air compressor

3 Inlet valve or diaphragm of brake valve

is not sealed

4 The bleed hole of pressure controlled

valve is clogged or the diaphragm of

check valve leaks air

1 Tighten the fitting

2 Check air compressor

3 Check and clean the inner parts of

brake valve, find out the unsealed

parts then repair

4 Clean air bleed hole, find out the

unsealed reasons of retaining valve

and diaphragm then repair.

Loading...

Loading...