Operation & Maintenance Manual──LG958L/LG959 Wheel Loader

34

z Please wear a uniform with a tight wristband and trousers. Always wear safety glasses.

z Please use the repair tools correctly; do not use broken or low quality tools.

z Lower the working equipment completely to the ground, stop the engine, push the parking brake

switch, and wedge the tire during repairs to prevent bodily injury.

z Obey the rules of warning labels. Pay attention to the important notices on the label on the

machine and obey the rules. Add a new one or clean the label if it is lost or dirty.

z Attach the label of “No Operation” or other warning label to the switches or control board

during repairs. Never let other people operate control levers (or control handles) or start the

engine to prevent injury or death.

z Fuel, mobile oil, grease and an oily cloth are

dangerous materials which should be kept away from

fire or flame. Do not pile oily cloths anywhere

because it may self-ignite.

z Never smoke when adding fuel or examining the

storage battery.

z Put the accessories in a safe place to prevent lost. Put

the handrail around and put the “No Enter”warning

label to prevent people from entering without

permission.

z No people are allowed to get close to the machine or

accessories without permission.

z Keep the working area clean and tidy, without oily

cloth or flammable lubricant oil (or grease) around to

prevent fire or slippage.

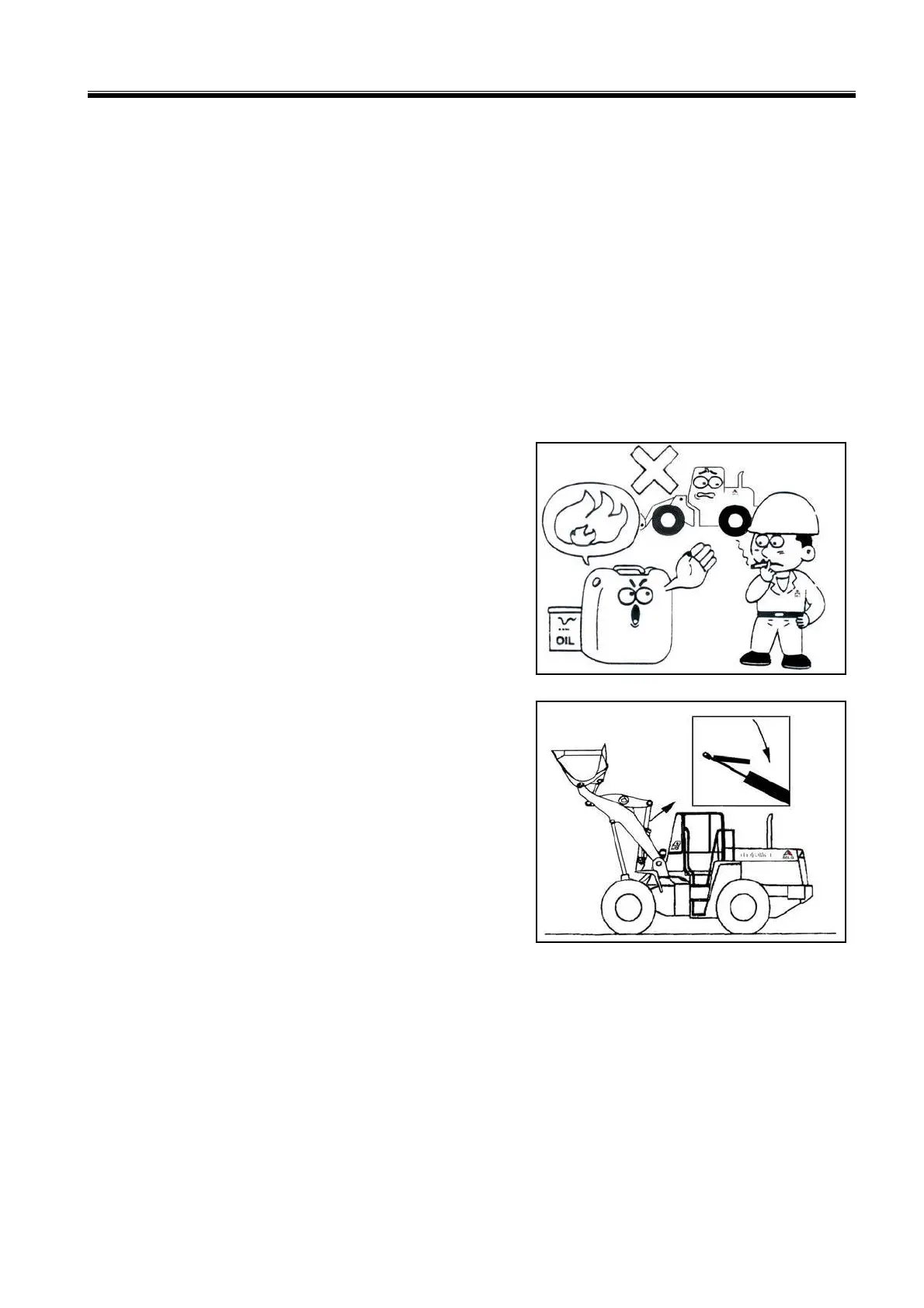

z Lock the front and rear frames with a safety bar to

prevent rotation before examination and repair.

z Make sure all the levers (or handles) are in the mid position and use the necessary equipment to

support the life-arms cylinder and tilting oil cylinder to prevent the working equipment from

falling if you have to examine and repair when the bucket is lifting.

8.2 Working in a Close Area

Exhaust gas from the engine may cause disease or death. If working in a close area, use releaser to

release the exhaust gas in the area. If there is no releaser, please open the door.

Loading...

Loading...