JACK 1600 JACK 1600

Note: The frequency of use is valid only for the first hour at 68°F

room Temperature.

Jack 1600 Lyra

13,12 feet

1600 pound

12

13

14

15

15

16

17

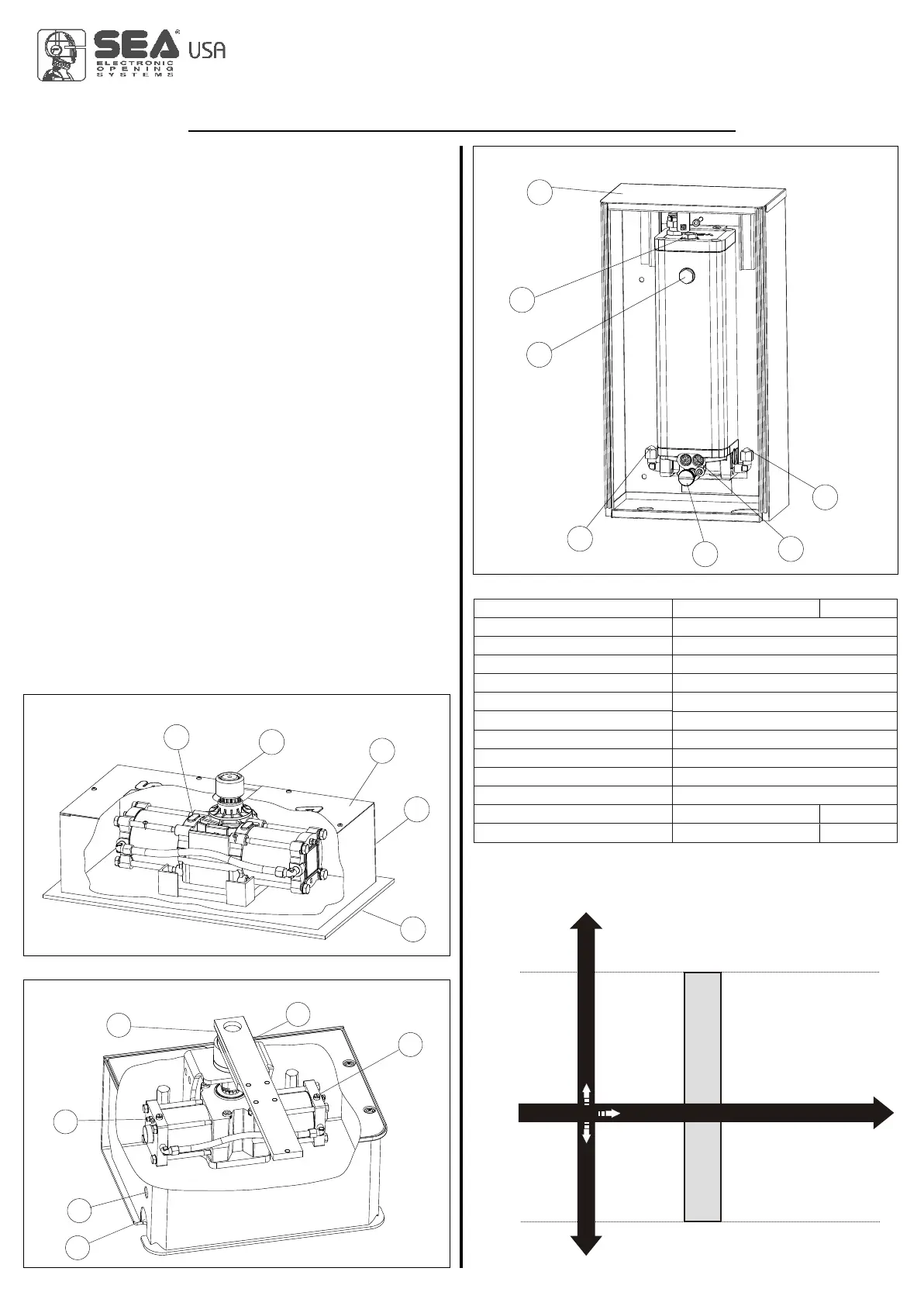

Fig. 8

1

2

3

4

5

Fig. 6

6

7

8

9

10

11

CARRYING BOX

Fig. 7

120 V~

220W

500 rpm

45

-4°F +131°F

130°

56 da N

60 µF

1600 Pound

IP67

17,63 Pound

-

REV 00 - 03/2014

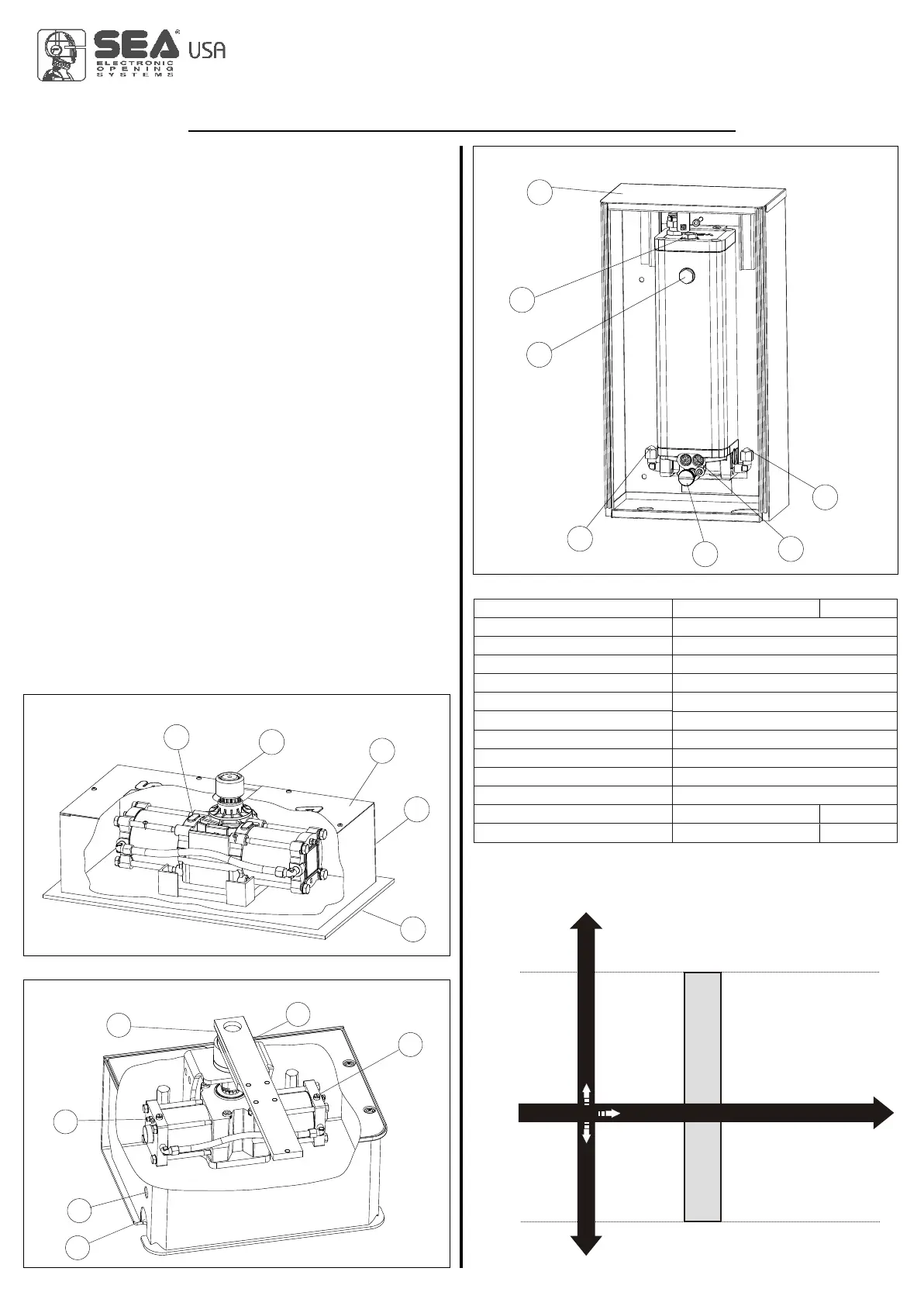

100° - 140° - 180°

-

MAIN PARTS NOMENCLATURE

TECHNICAL DATA

Power supply

Motor Power

Motor rotation speed

Cycles hour (with a 20°C temp.)

Operating temperature

Thermal protection intervention

Max torque

Starting capacitor

Weight

Protection class

Maximum weight of the gate

Max leaf weight

Max leaf width

Underground hydraulic operators

GRAPHIC FOR THE USE OF

JACK 1600 OPERATORS

1 Jack

2 Broached bush

3 Box lid

4 Box

5 Foundation base

6 Braking screw

(where provided)

7 Exit hole for electric cables

8 Water draining hole

adjusting

9 Air bleed screw

10

11

12 Hydraulic unit box

13 Oil charge cap

14

15 Hydraulic plug

16 Release screw

17 By pass valves

Greaser

Crank

Oil level cap

NON-CARRYING BOX

LYRA HYDRAULIC UNIT

Jack rotation angle

1. FEATURES AND SPECIFICATIONS

The LYRA JACK consists of a hydraulic pump and a hydraulic

jack. The jack is placed inside a non carrying or carrying box

(inox only for carrying box).

The pump unit casing, which is used as an oil tank, contains the

electric motor, fluid pump, distributor and hydraulic oil. It is also

provided with an adjustable slowing-down device in the two

stop phases of the leaf (versions with slow-down only).

The wheeling unit is composed by a double piston connected to

a rack which engages with the pinion of the leaf dragging shaft.

Gates up to 6,56 feet long can be securely locked using the

operators internal hydraulic locking system, thus ensuring

perfect keeping in closing and in opening. For gate in excess of

stated value: A hydraulic non locking operator should be used in

conjunction with a separate electrical locking device to ensure

keeping in closing.

On the operators with hydraulic slow down it is present

only during the last 15° of rotation. The system comes with a

release which allows the manual opening of the leaves in case of

power failure.

MECHANICAL INSTALLATION

International registered trademark n. 2.777.971

LYRA, JACK

674117856

Loading...

Loading...