INSTALLATION

MANUAL

Section 1: MECHANICAL INSTALLATION

1.0 Introduction

This document is intended to give details and guidance to a boat builder or equipment installer to

install the Seakeeper 9. The Seakeeper 9 is capable of producing loads up to 17.09KN (3,842

lbs.) at each of the four mounts and careful consideration should be given to foundation design to

ensure it is capable of transferring these loads into the hull. These loads do NOT include vessel

motion accelerations, such as vertical slam loads which can be significant for high-speed vessels.

The responsible party for designing the supporting structure (boat builder, installer, or hired sub-

contractor) must accommodate the above forces plus a reasonable factor of safety. Seakeeper

recommends a minimum safety factor of 3.0.

It is assumed that the installer is familiar with installing mechanical fasteners in marine

structures or using high strength adhesives on aluminum and fiberglass (FRP), and has

performed structural analysis to assure the structure to which the Seakeeper mounts can

properly transfer the loads the Seakeeper creates into the hull structure. If the installer

has any doubt about the ability of the structure to transfer the loads to the hull, then a

licensed naval architect or marine engineer should be contacted to perform a structural

analysis.

The installer should review the following list of reference drawings to ensure the mechanical

installation procedure is fully understood.

Reference Drawings

Seakeeper 9 Hardware Scope of Supply

Seakeeper 7HD Hardware Scope of Supply

Seakeeper 9/7HD Installation Details – Bolt in Method

Seakeeper 9/7HD Installation Details – Bond in Method

Seakeeper 9/7HD Cooling Water Schematic

Seakeeper 9/7HD Installation Template Kit

Seakeeper 9/7HD Cable Block Diagram

Seakeeper 9/7HD Generic Installation Guide

Seakeeper 9/7HD Bolt-In Clearances

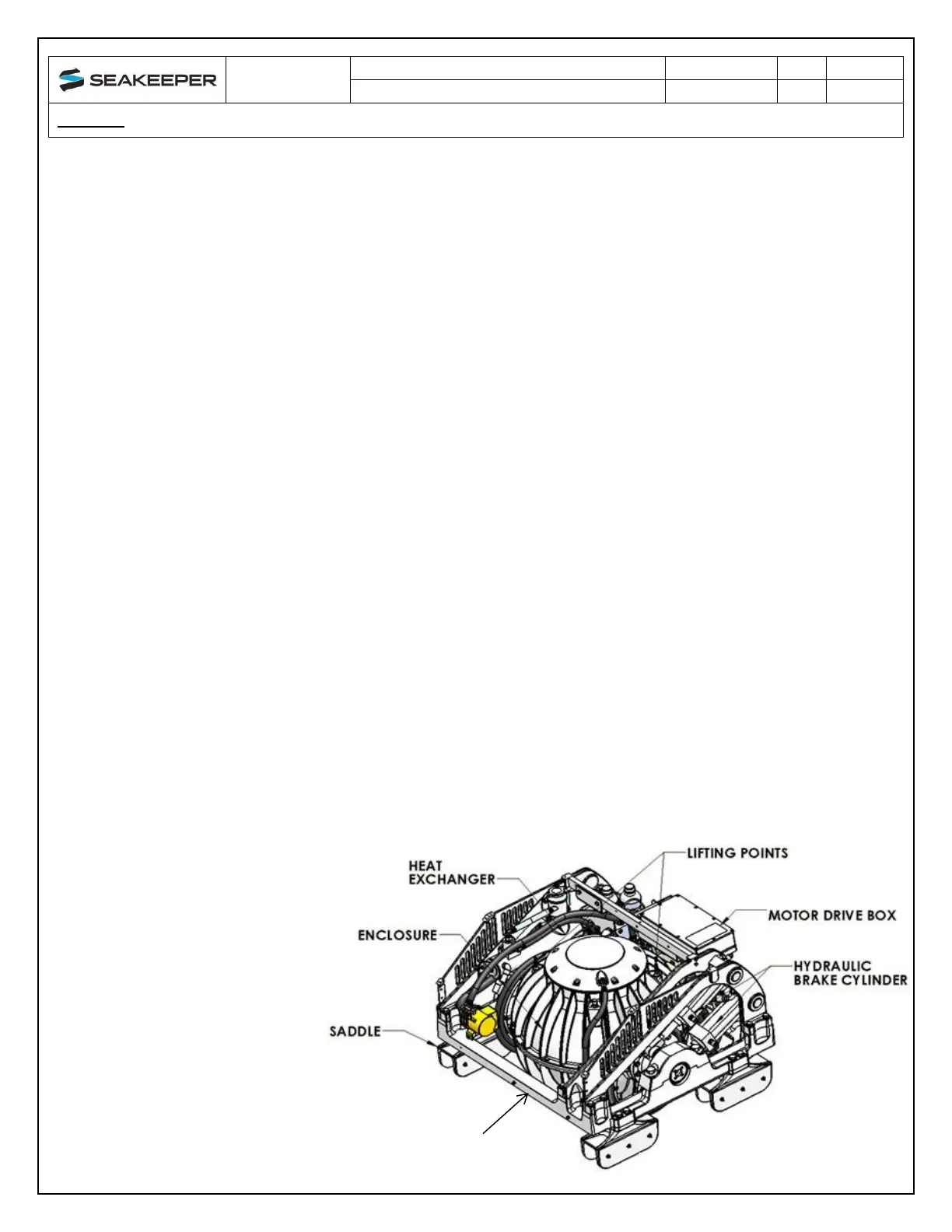

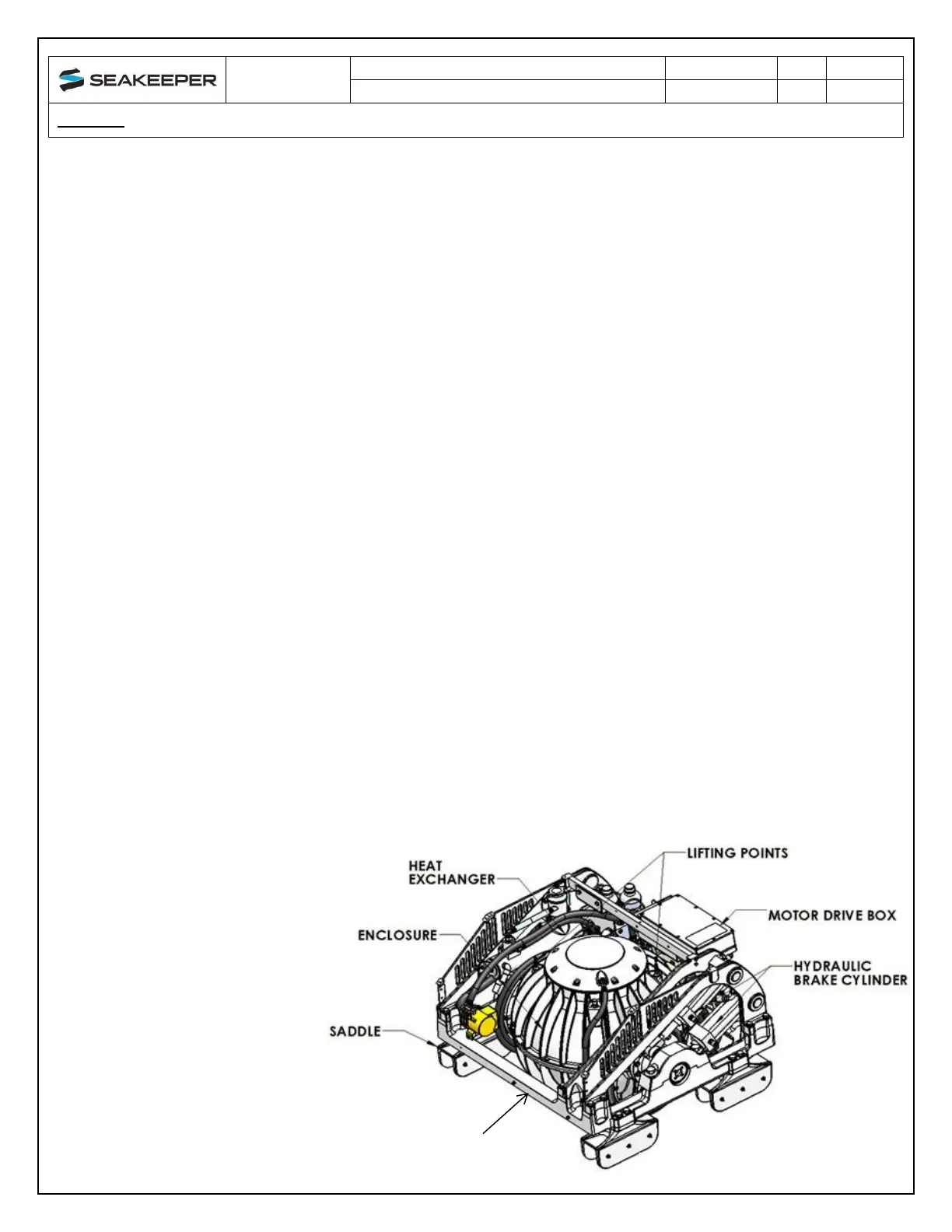

FIGURE 1 – SEAKEEPER 9

Foundation

Loading...

Loading...