START-UP

Once

all the aforementioned operations have been completed, the pump is ready to be started.

Priming

- Start the pump.

- Open the priming connector by turning the knob in a counter-clockwise direction and wait for liquid to come out of the pipe

connected to it.

- Once you are sure that the pump is completely full of liquid, you can close the connector and the pump will begin to dose.

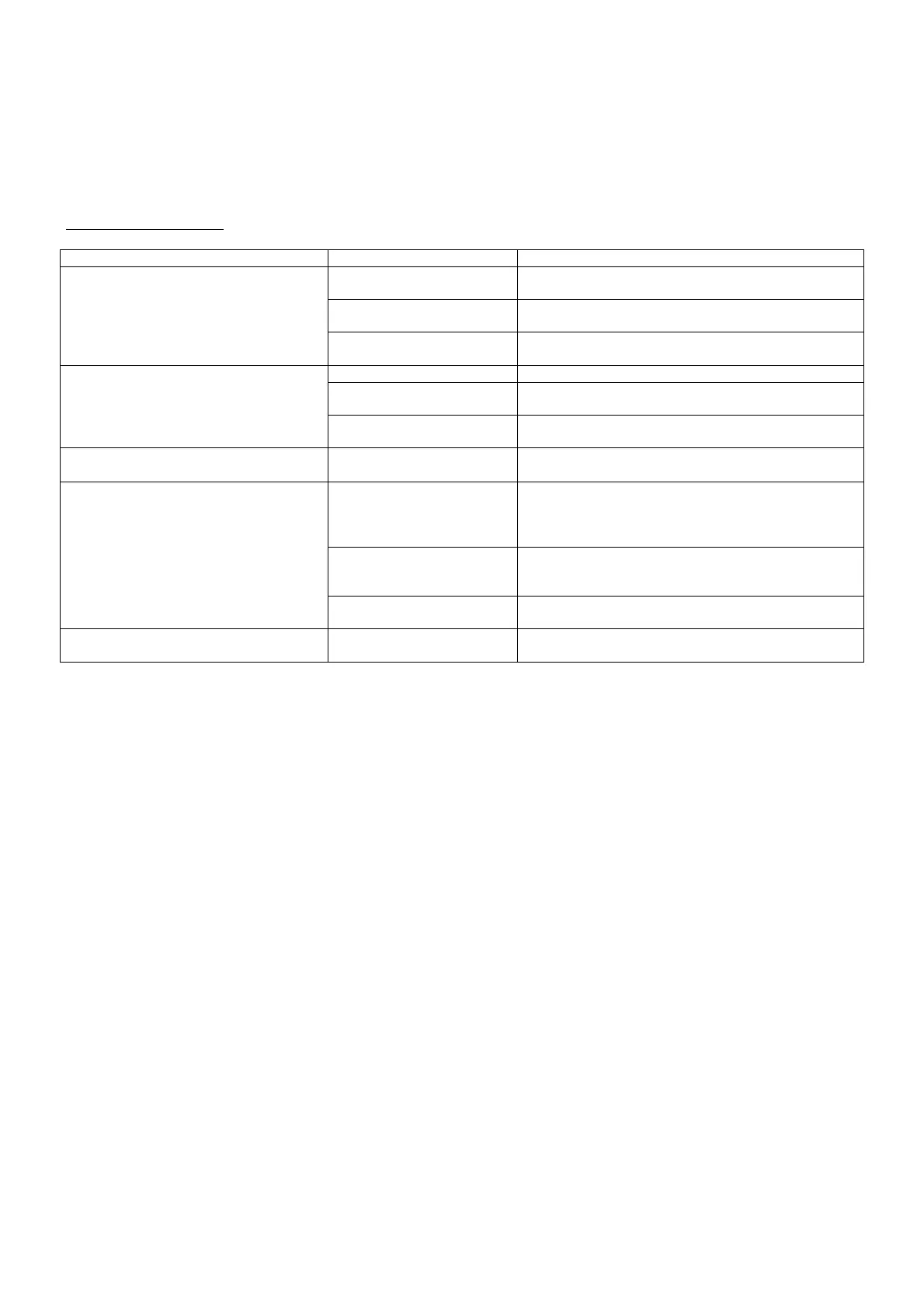

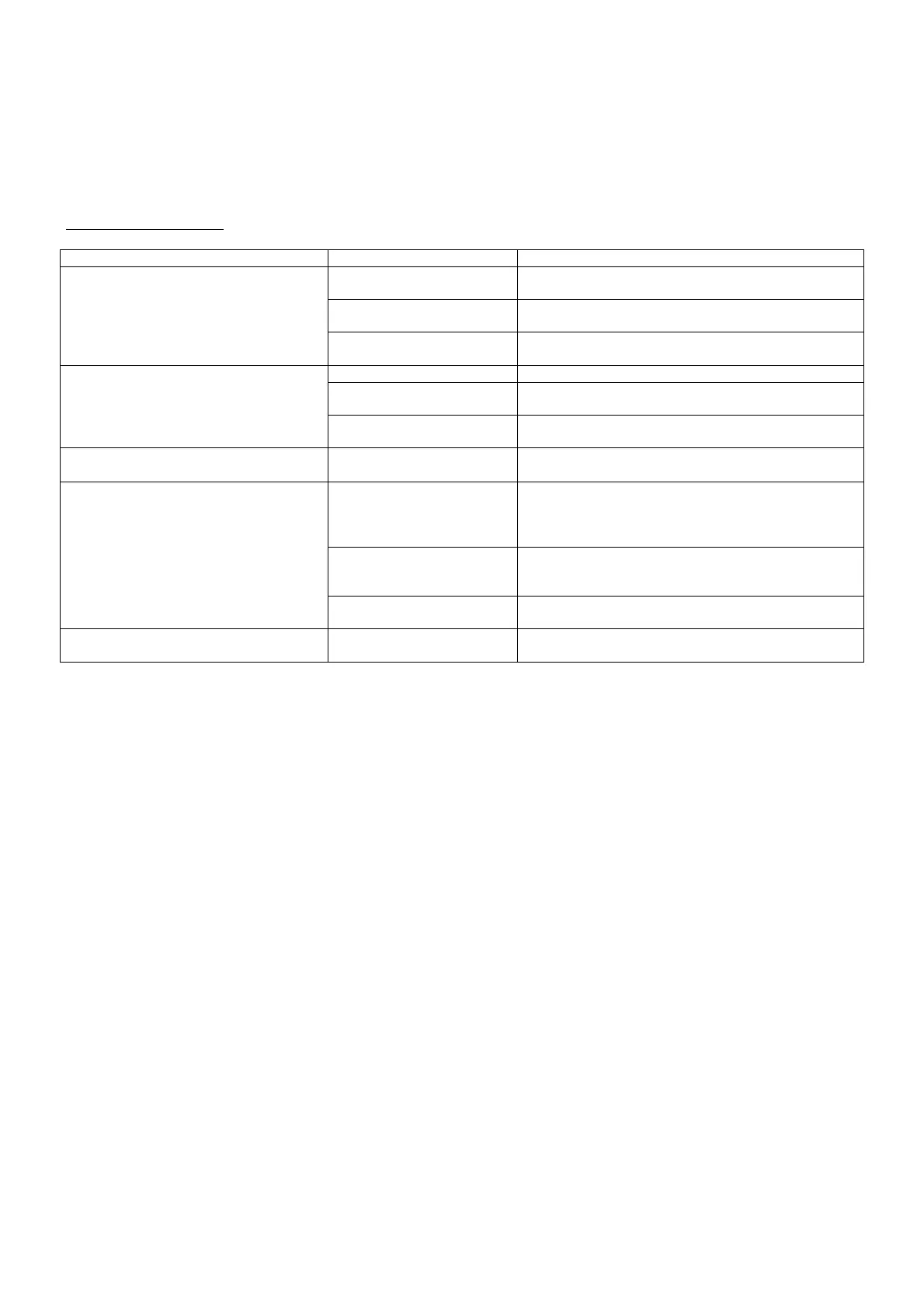

TROUBLESHOOTING

The pump is working properly but the

dosage is interrupted

Clean the valves or replace them if it is not possible

to remove the build-ups

Position the pump or tank so as to reduce the

suction height

Excessive liquid viscosity

Reduce the suction height or use a pump with a

bigger flow capacity

Insufficient flow capacity

Check that the ring nuts are properly tightened

Excessive liquid viscosity

Use a pump with a bigger flow capacity or reduce

the suction height

Clean the valves or replace them if it is not possible

to remove the build-ups

Irregular pump flow capacity

Transparent PVC hose on

delivery

Use an opaque PE pipe on delivery

Check the system pressure. Check whether the

injection valve is blocked. Check whether there are

any blockages between the delivery valves and the

injection point.

Check the presence of the foot filter (valve). Use a

level probe that blocks the pump when the chemical

product runs out in the tank

Membrane not secured

correctly

If the membrane has been replaced, make sure that

the same is correctly tightened.

The pump does not switch on

Insufficient power supply

Check whether the pump plate data corresponds to

that of the electricity network.

Loading...

Loading...