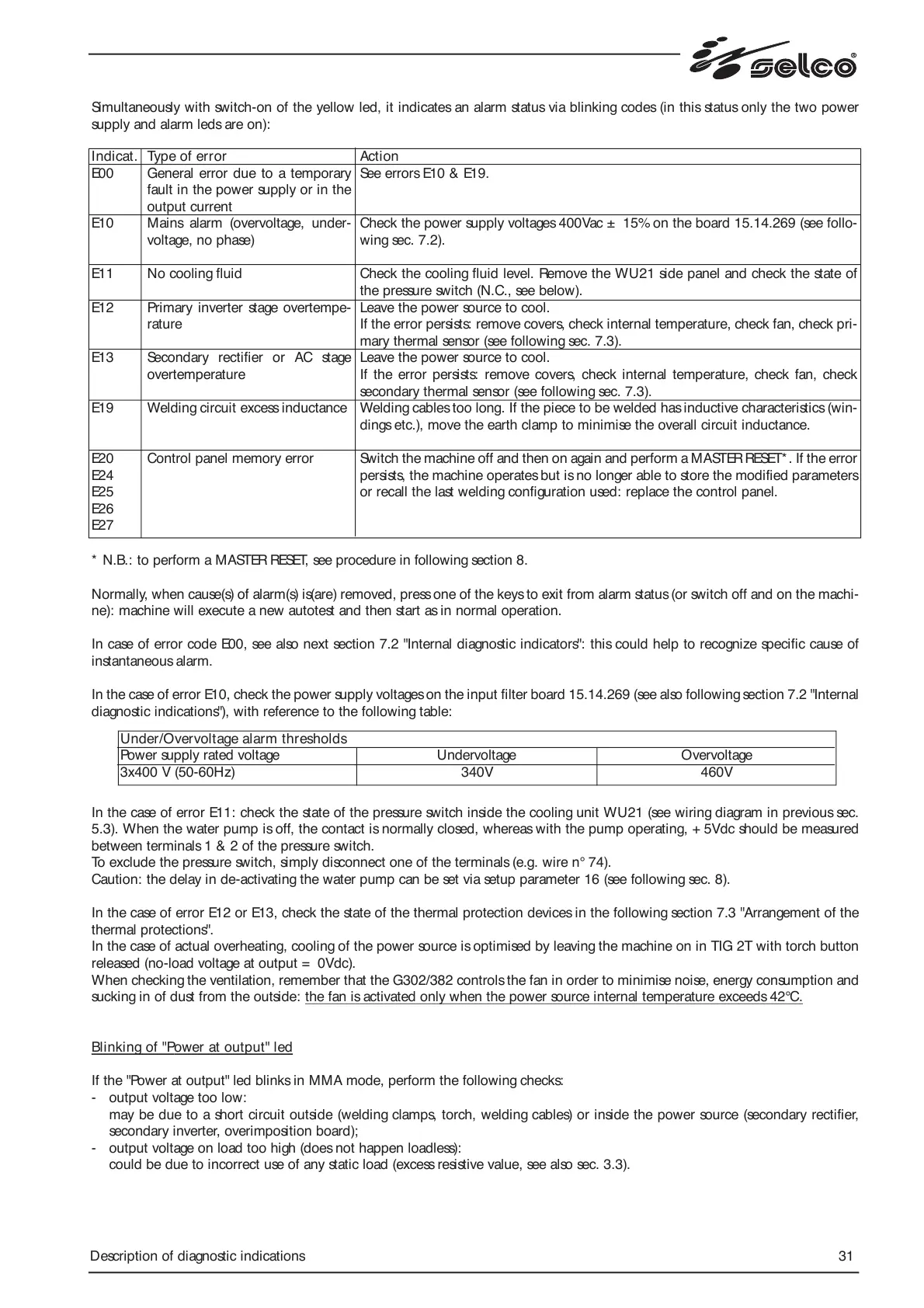

Simultaneously with switch-on of the yellow led, it indicates an alarm status via blinking codes (in this status only the two power

supply and alarm leds are on):

* N.B.: to perform a MASTER RESET, see procedure in following section 8.

Normally, when cause(s) of alarm(s) is(are) removed, press one of the keys to exit from alarm status (or switch off and on the machi-

ne): machine will execute a new autotest and then start as in normal operation.

In case of error code E00, see also next section 7.2 "Internal diagnostic indicators": this could help to recognize specific cause of

instantaneous alarm.

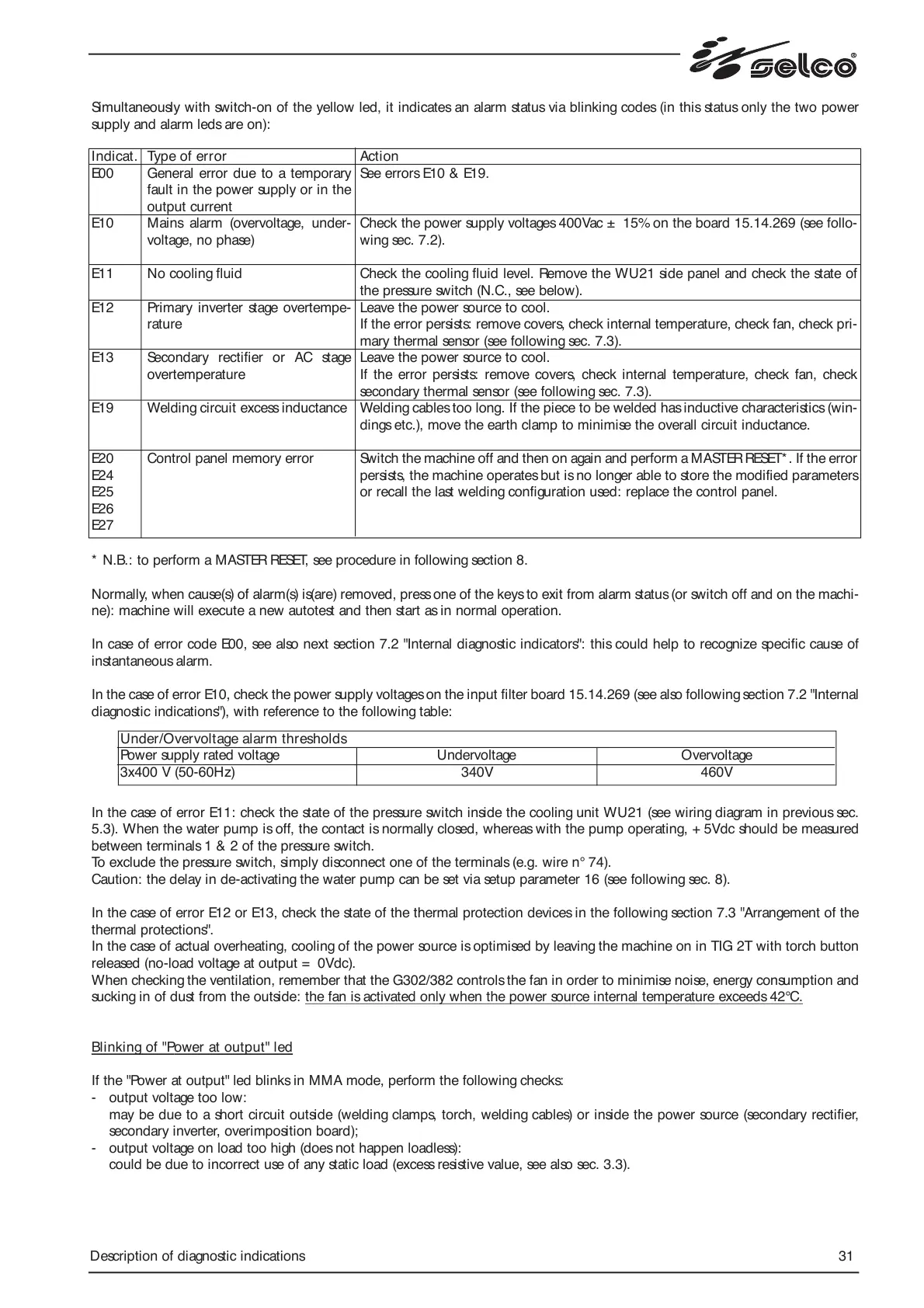

In the case of error E10, check the power supply voltages on the input filter board 15.14.269 (see also following section 7.2 "Internal

diagnostic indications"), with reference to the following table:

In the case of error E11: check the state of the pressure switch inside the cooling unit WU21 (see wiring diagram in previous sec.

5.3). When the water pump is off, the contact is normally closed, whereas with the pump operating, + 5Vdc should be measured

between terminals 1 & 2 of the pressure switch.

To exclude the pressure switch, simply disconnect one of the terminals (e.g. wire n° 74).

Caution: the delay in de-activating the water pump can be set via setup parameter 16 (see following sec. 8).

In the case of error E12 or E13, check the state of the thermal protection devices in the following section 7.3 "Arrangement of the

thermal protections".

In the case of actual overheating, cooling of the power source is optimised by leaving the machine on in TIG 2T with torch button

released (no-load voltage at output = 0Vdc).

When checking the ventilation, remember that the G302/382 controls the fan in order to minimise noise, energy consumption and

sucking in of dust from the outside: the fan is activated only when the power source internal temperature exceeds 42°C.

Blinking of "Power at output" led

If the "Power at output" led blinks in MMA mode, perform the following checks:

- output voltage too low:

may be due to a short circuit outside (welding clamps, torch, welding cables) or inside the power source (secondary rectifier,

secondary inverter, overimposition board);

- output voltage on load too high (does not happen loadless):

could be due to incorrect use of any static load (excess resistive value, see also sec. 3.3).

Indicat.

E00

E10

E11

E12

E13

E19

E20

E24

E25

E26

E27

Description of diagnostic indications 31

Type of error

General error due to a temporary

fault in the power supply or in the

output current

Mains alarm (overvoltage, under-

voltage, no phase)

No cooling fluid

Primary inverter stage overtempe-

rature

Secondary rectifier or AC stage

overtemperature

Welding circuit excess inductance

Control panel memory error

Action

See errors E10 & E19.

Check the power supply voltages 400Vac ± 15% on the board 15.14.269 (see follo-

wing sec. 7.2).

Check the cooling fluid level. Remove the WU21 side panel and check the state of

the pressure switch (N.C., see below).

Leave the power source to cool.

If the error persists: remove covers, check internal temperature, check fan, check pri-

mary thermal sensor (see following sec. 7.3).

Leave the power source to cool.

If the error persists: remove covers, check internal temperature, check fan, check

secondary thermal sensor (see following sec. 7.3).

Welding cables too long. If the piece to be welded has inductive characteristics (win-

dings etc.), move the earth clamp to minimise the overall circuit inductance.

Switch the machine off and then on again and perform a MASTER RESET*. If the error

persists, the machine operates but is no longer able to store the modified parameters

or recall the last welding configuration used: replace the control panel.

Under/Overvoltage alarm thresholds

Power supply rated voltage

3x400 V (50-60Hz)

Undervoltage

340V

Overvoltage

460V

Loading...

Loading...