19

18

DEUTSCHESPAÑOL ITALIANO ENGLISHFRANCIS

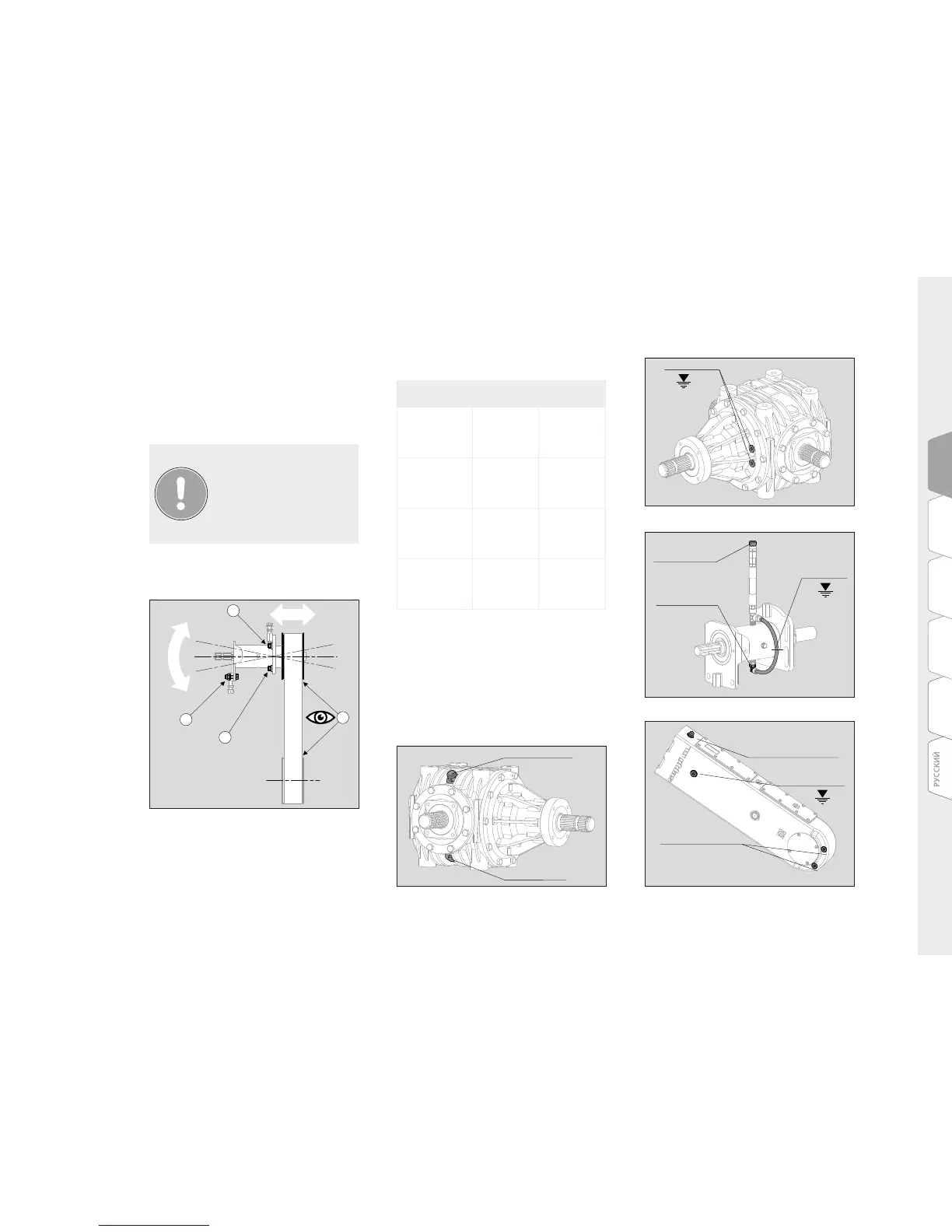

6.2 Lubrication

6.2.2 Changing oil

Before starting lubrication, clean all the lubri-

cation points with a rag.

Use grease pumps with clean nozzles to avoid

introducing impurities into the lubrication

points.

After the first 50 hours, and then every 500

hours, it is necessary to change the gearbox oil.

Respect the following levels:

- Gearbox

During a test start, always

remain a safety distance away

of at least 2 m and NEVER turn

the adjustment screws while

the machine is running. Wait

for it to come to a full stop

before resuming maintenance.

6) Repeat the points above until the pulleys are

perfectly aligned

7) The pulleys are perfectly aligned when the belt

remains in the middle of the pulley

6.2.1 Recommended lubricant

Model Component Oil

MIDIPIERRE

MIDIPIERRE dt

MULTIFORST

Gearbox

SYNTHETIC

GEAR OIL ISO

220

(DIN 51502)

SUPERSOIL

MAXISOIL

Gearbox

SYNTHETIC

GEAR OIL ISO

320

(DIN 51502)

All models Extensions SYNTHETIC

GEAR OIL

ISO 220 (DIN

51502)

MIDISOIL dt

STARSOIL

Parallel gear

transmission

SYNTHETIC

GEAR OIL

ISO 150 (DIN

51502)

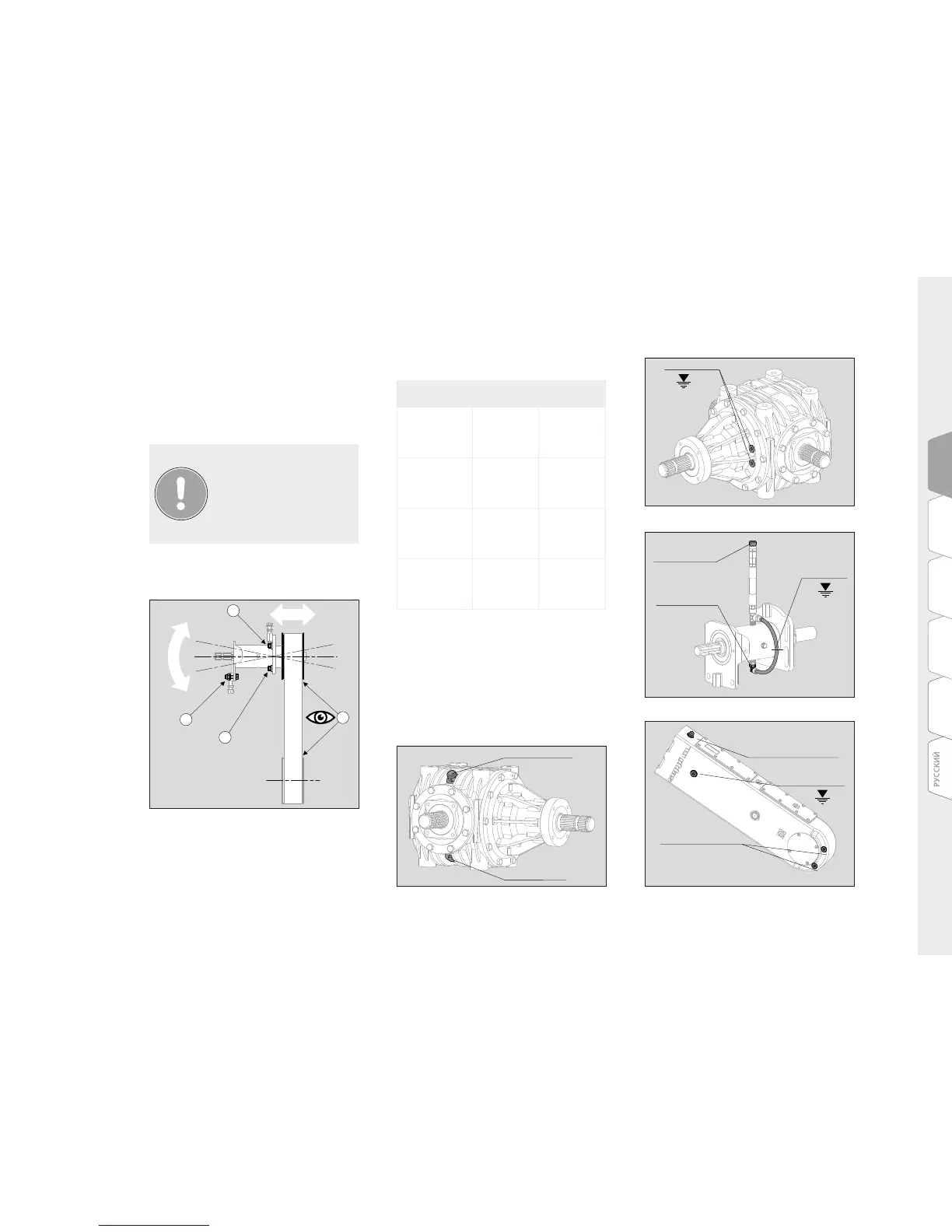

3)

Act on the tie rod to change angling of the

extension

4) Tighten the remaining screws to fix the exten

-

sion

5) Visually check alignment by starting the

machine briefly without belt protections and

without load

- Extensions

- gear transmission

3

1

5

2

Breather filler cap

Breather cap

and drain plug

Breather filler cap

Drain plugs

Oil level

Breather filler

cap

Drain plug

Oil level

Oil level

Loading...

Loading...