21

20

DEUTSCHESPAÑOL ITALIANO ENGLISHFRANCIS

7) block the stop screws of the previously re-

moved bars

8) reinstall the closures and belt protections

9) lower the hood

4) remove the stop screws of the bars

OPT 214 OPT 228, 141

5) using a round bar with a diameter 5 mm less

than that of the hammer support bar, pull them

off by hitting one of the two ends. If the bars are

warped, they must be cut in pieces.

6) re-insert the bars in the rotor, inserting the

new hammers one by one

If only one hammer needs to be

replaced (e.g. broken), it is ad-

visable to use hammers already

worn, with a shape and weight

similar to those mounted.

6.5.2 Replacing fixed knives

To remove and replace the fixed knives, proceed

as follows:

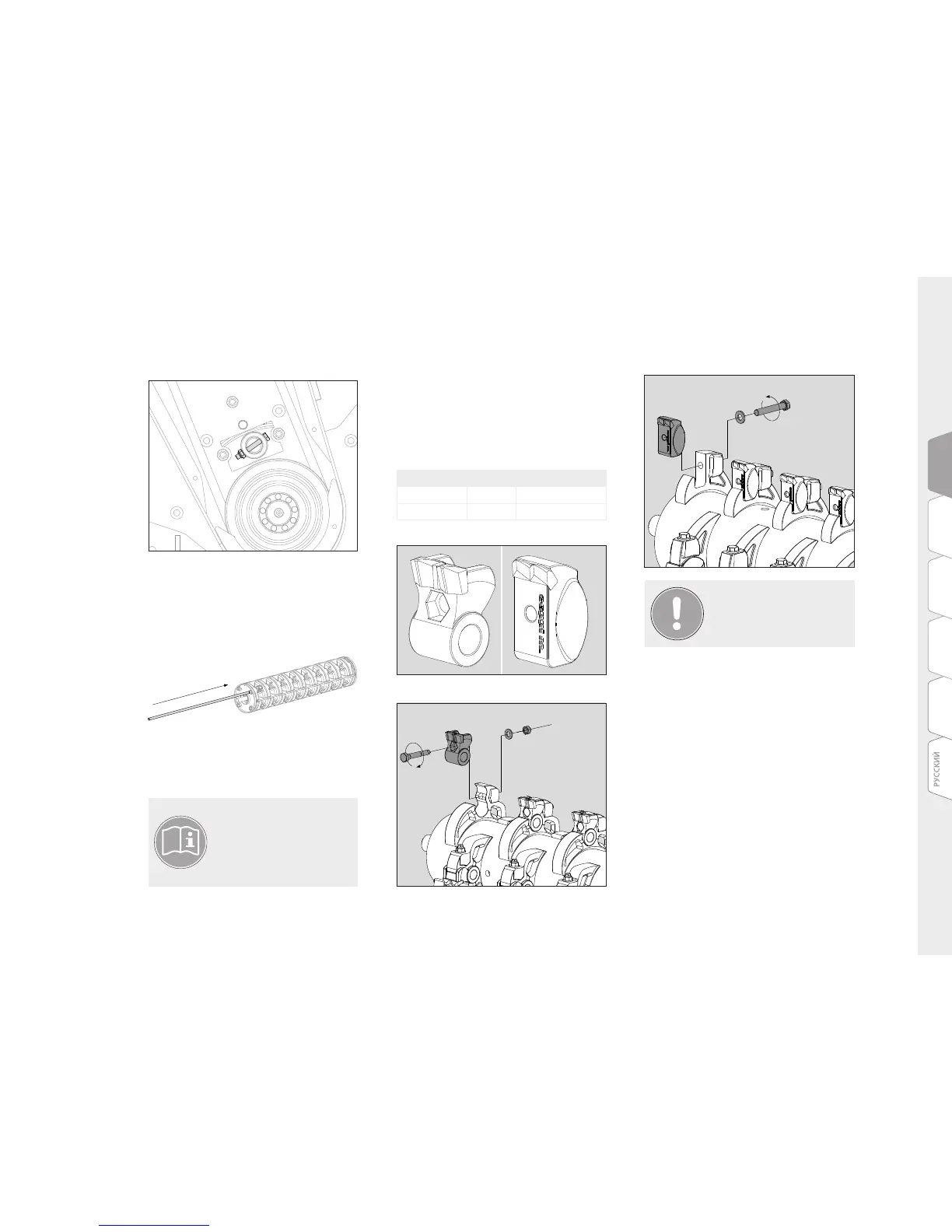

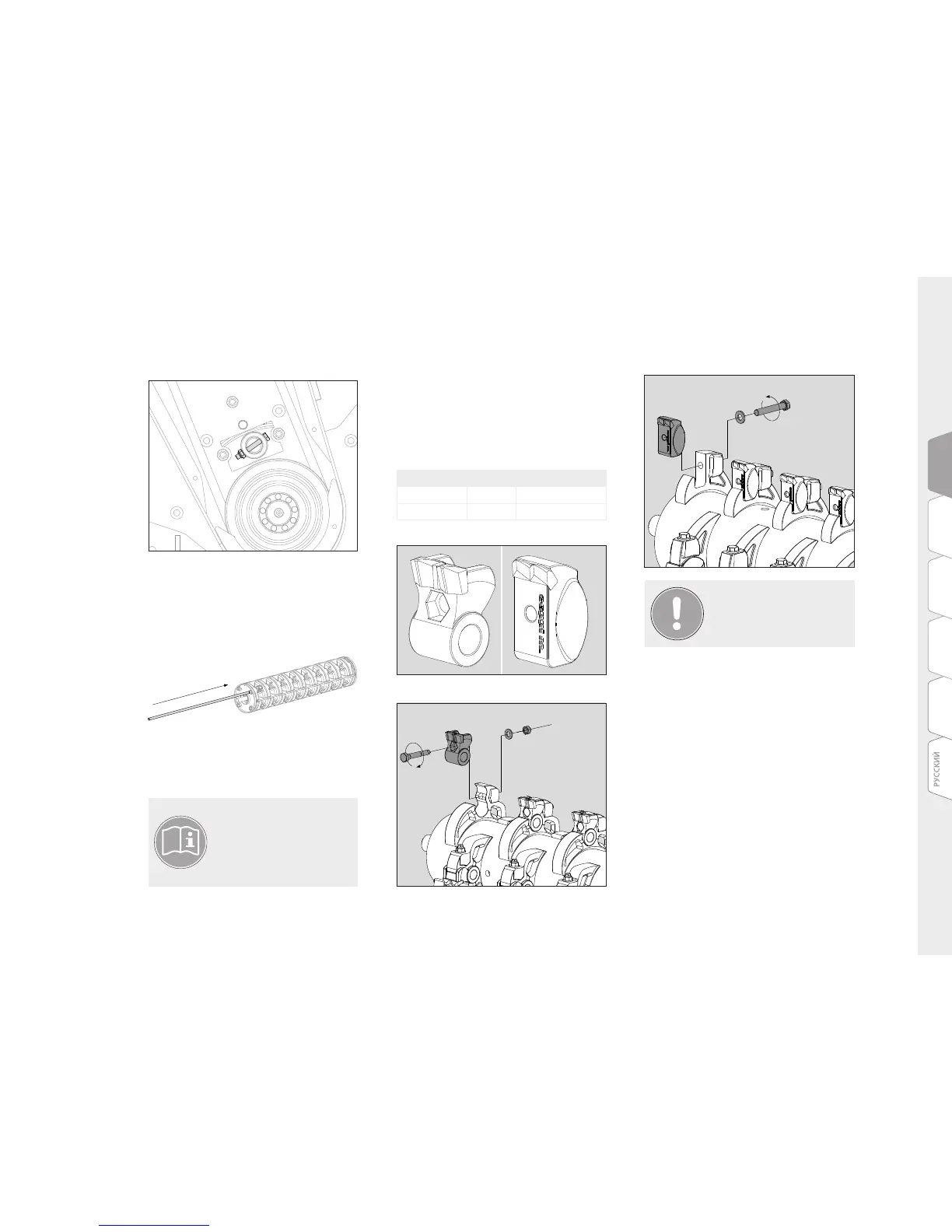

1) remove the fixing screw from the knife

2) remove the knife from its seat

3) replace the knife, screw, nut and tapered wash

-

er (if present)

4) tighten the screw at the following torques:

Rotor Screw Tightening torque

OPT 214 M16 350 NM (258 lb ft)

OPT 228, 141 M16 350 NM (258 lb ft)

After about one hour of work,

check that the new hammer is

tightened properly.

Assembling OPT 214

350 NM

(258 lb ft)

Assembling OPT 228

350 NM

(258 lb ft)

6.6 Replacing anti-wear frame

The anti-wear frame must be checked after

each day of work. Change it when worn to avoid

wearing the main frame.

6.7 Checking screws

Frequently inspect the machine, making sure

that all components are properly fastened and

that all screws and nuts are well-clamped.

Before starting particularly heavy duty work,

check the maintenance status.

6.8 Troubleshooting

The following are the main, reasonably fore-

seeable, malfunctioning conditions in relation

to the individual operational functions of the

machine.

(> see next page)

Loading...

Loading...