21

20

The cooling circuit guarantees correct lubrication

and ideal temperatures for the gearboxes. Always

check that the cooling system works properly.

The filters must be changed every time oil is

changed.

6.2.3 Cooling system

(MIDISOIL dt, STARSOIL)

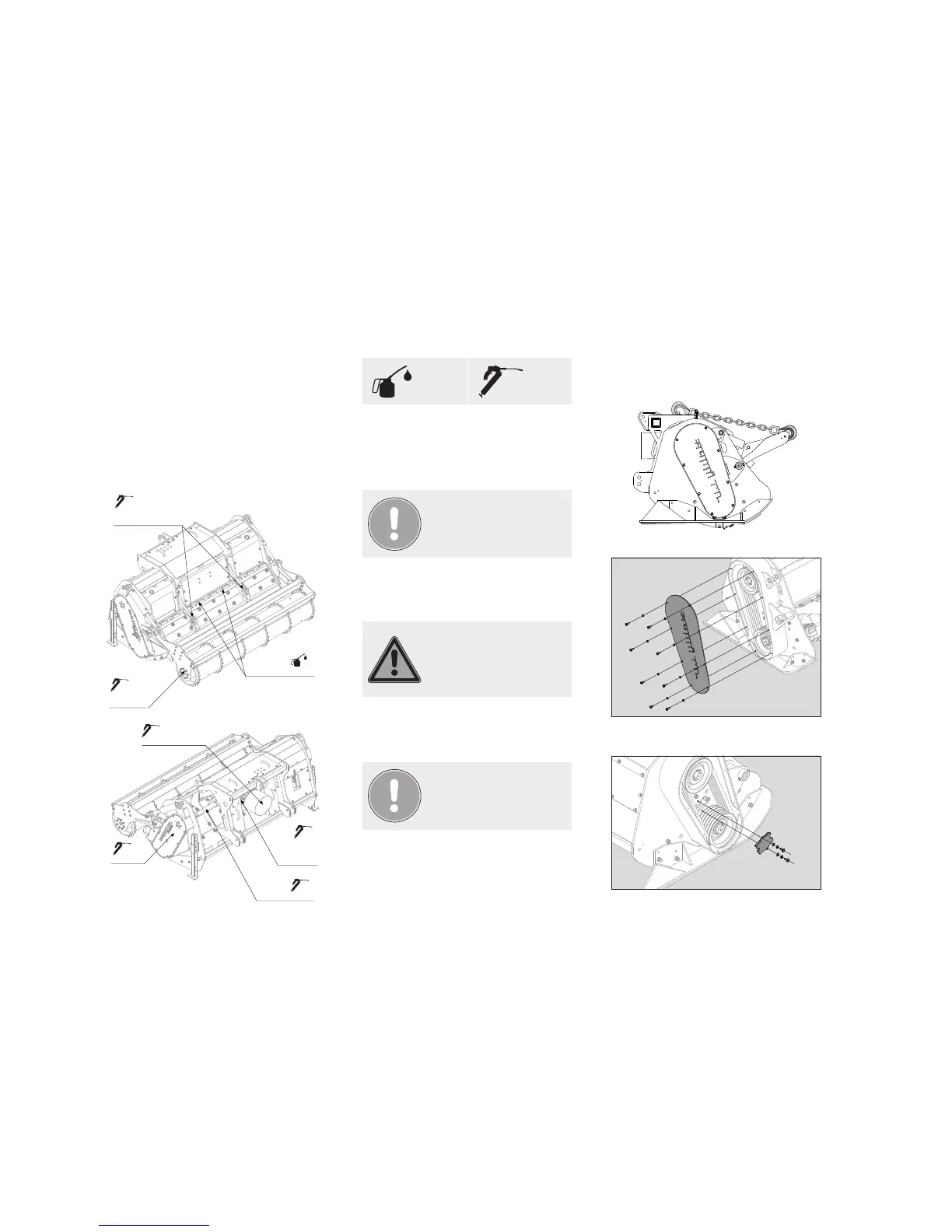

6.2.4 Lubrication plan

Oil Grease

PTO shaft

40 h

Gearbox

rotation

40 h

PTO shaft

40 h

Rotor

8 h

40 h

hood bushes

Hood opening

cylinders joints

40 h

roller

bearing

8 h

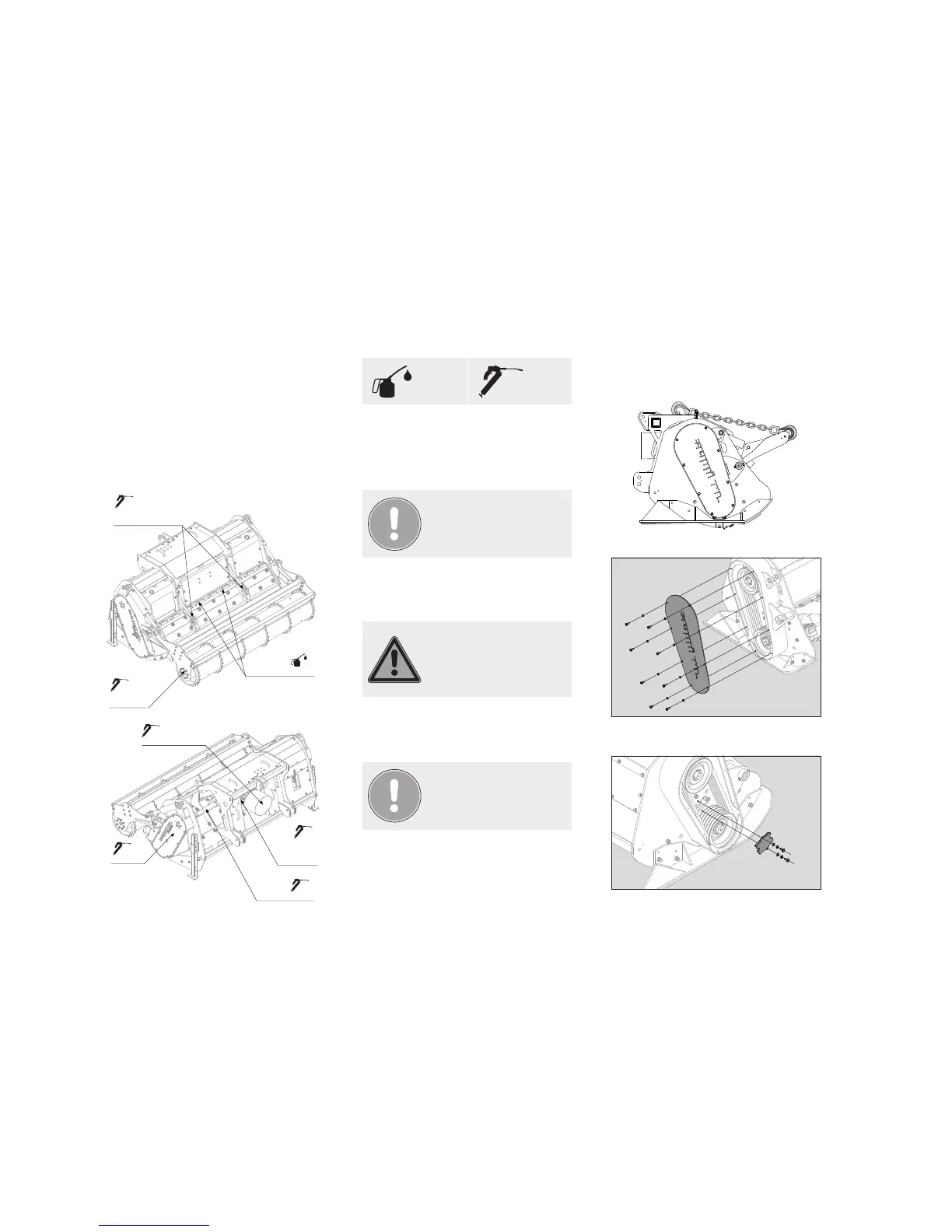

6.5.1 Replacing swinging hammers

To remove and replace the swinging hammers,

proceed as follows:

2) open the belt protection cover

3)

disassemble the closures, installed at the sides of the

machine, to be able to pull out the hammer support bars

If damaged or worn, restore

them immediately, as well as

safety stickers if damaged or

missing.

6.3 Oil leaks

6.5 Replacing tools

6.4 Safety devices and information

If any machine component leaks oil, the oil

must be recovered and worn components

restored.

Use original Seppi components for proper

operation of the rotor.

Check the chains, rubbers, guards of the PTO

shaft, etc. every 8 hours

Oil leakage on the ground

causes pollution!

Using non-original spare parts

makes the rotor warranty null

and void.

1) lift the rear hood with the hydraulic controls

and secure it mechanically

against accidental closures

Loading...

Loading...