PAGE 11

PAGE 10

PREPARATION FOR STARTING

6. Open the outlet valve, set the

power switch knob to position “on”

and let the compressor run for 10

minutes with no load to ensure the

moving parts are lubricated before

regular service.

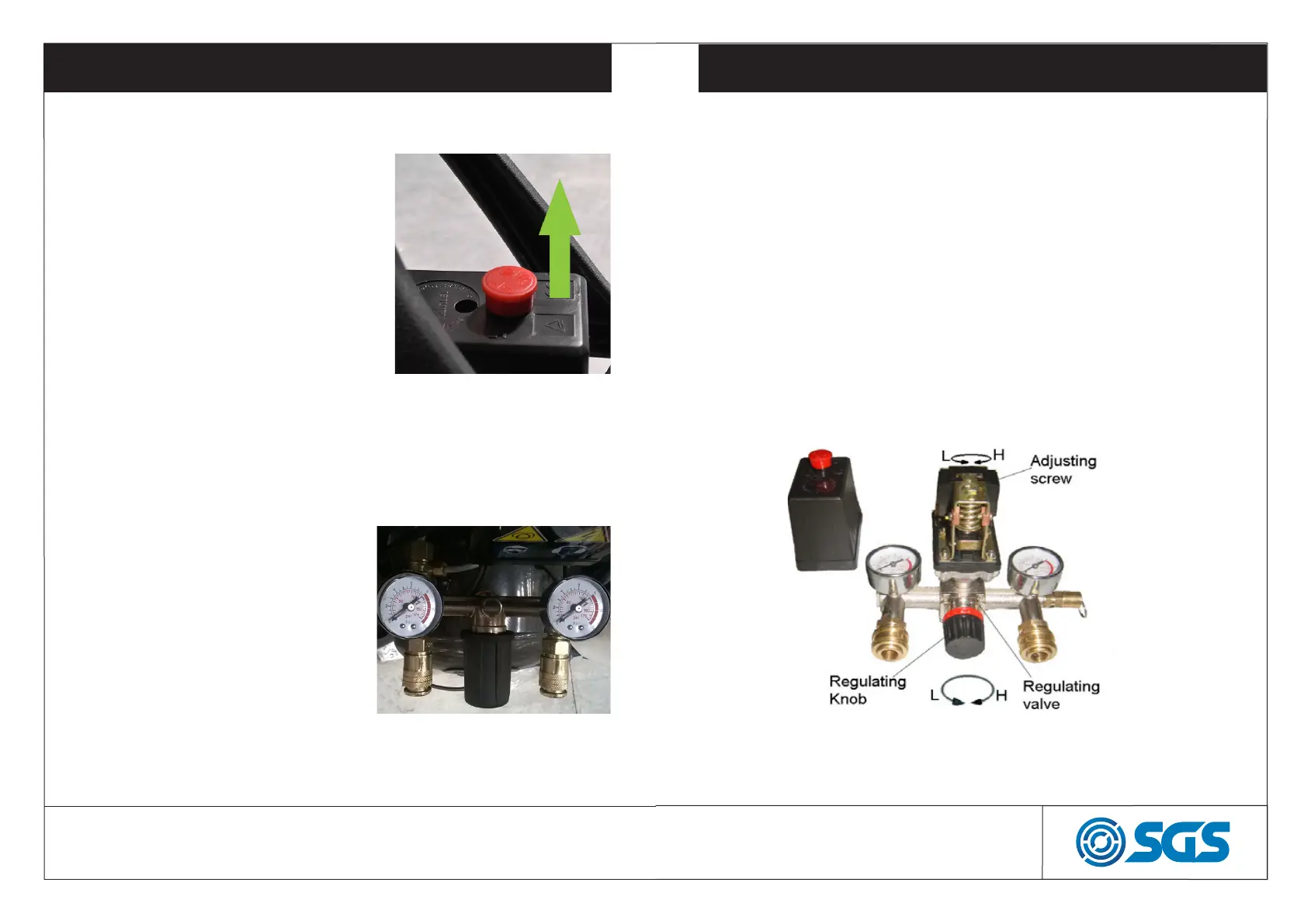

PRESSURE GAUGES

There are two pressure gauges on the

compressor.

1. The pressure gauge on the RIGHT

shows the current pressure in the

reservoir tank.

2. The pressure gauge on

the LEFT shows the ‘user set’ outlet

pressure. This can be adjusted using

the regulator.

1. The compressor is controlled by a pressure switch. It can be

stopped automatically as the pressure increases to the maximum

and restarted as pressure decreases to the minimum. The rated

pressure has been adjusted during the manufacturing process

- don’t alter it carelessly. As soon as the motor is switched off

the compressed air in the discharge pipe should be released

through the release valve under the switch. This is a necessary

condition before restarting or the motor will be damaged. The

rated pressure can be altered by turning the adjusting screw.

OPERATION AND ADJUSTMENT

WWW.SGS-ENGINEERING.COM

Loading...

Loading...