PAGE 15

PAGE 14

1. Before any maintenance operation stop

the air compressor, cut off the power

supply and discharge all air in the air

tank.

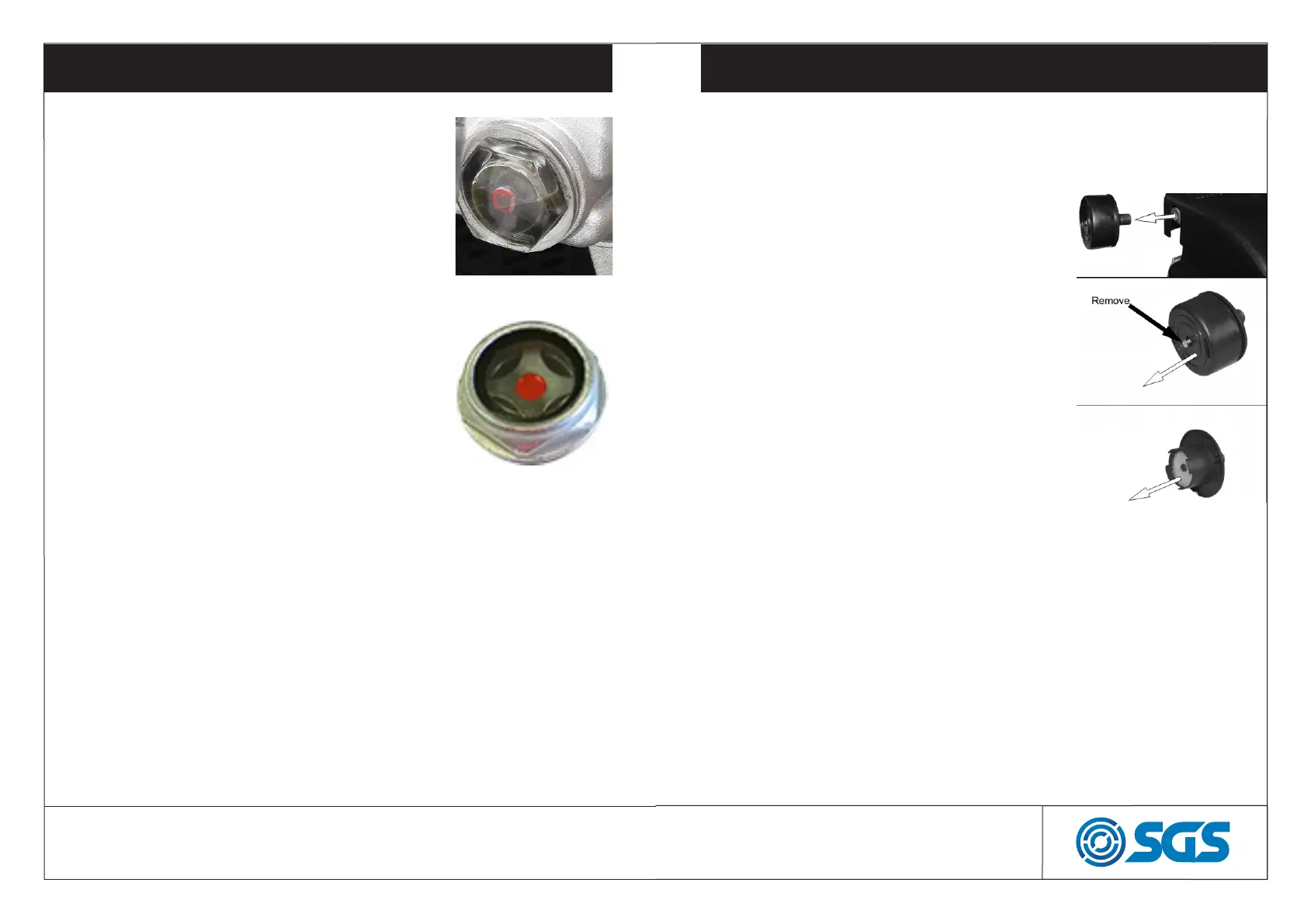

2. Clean crank case and renew lubricat-

ing oil after the first 10 working hours.

Check the oil level through the oil level

sightglass (1.) after every 20 working

hours and replenish if necessary- you can

replenish by unbolting the oil level sight-

glass, and draining off any old oil. (2.)

3. Have the safety valve and pressure

gauge checked by a certified repair cen-

tre every 6 months to ensure they are in

the correct working condition.

4. Make sure there is no rust on the air tank

and the air tank is not damaged.

5. Have the thickness of the air tank

checked by a certified repair centre

every year to ensure the tank thickness is

not less than 2.1mm.

MAINTENANCE

MAINTENANCE

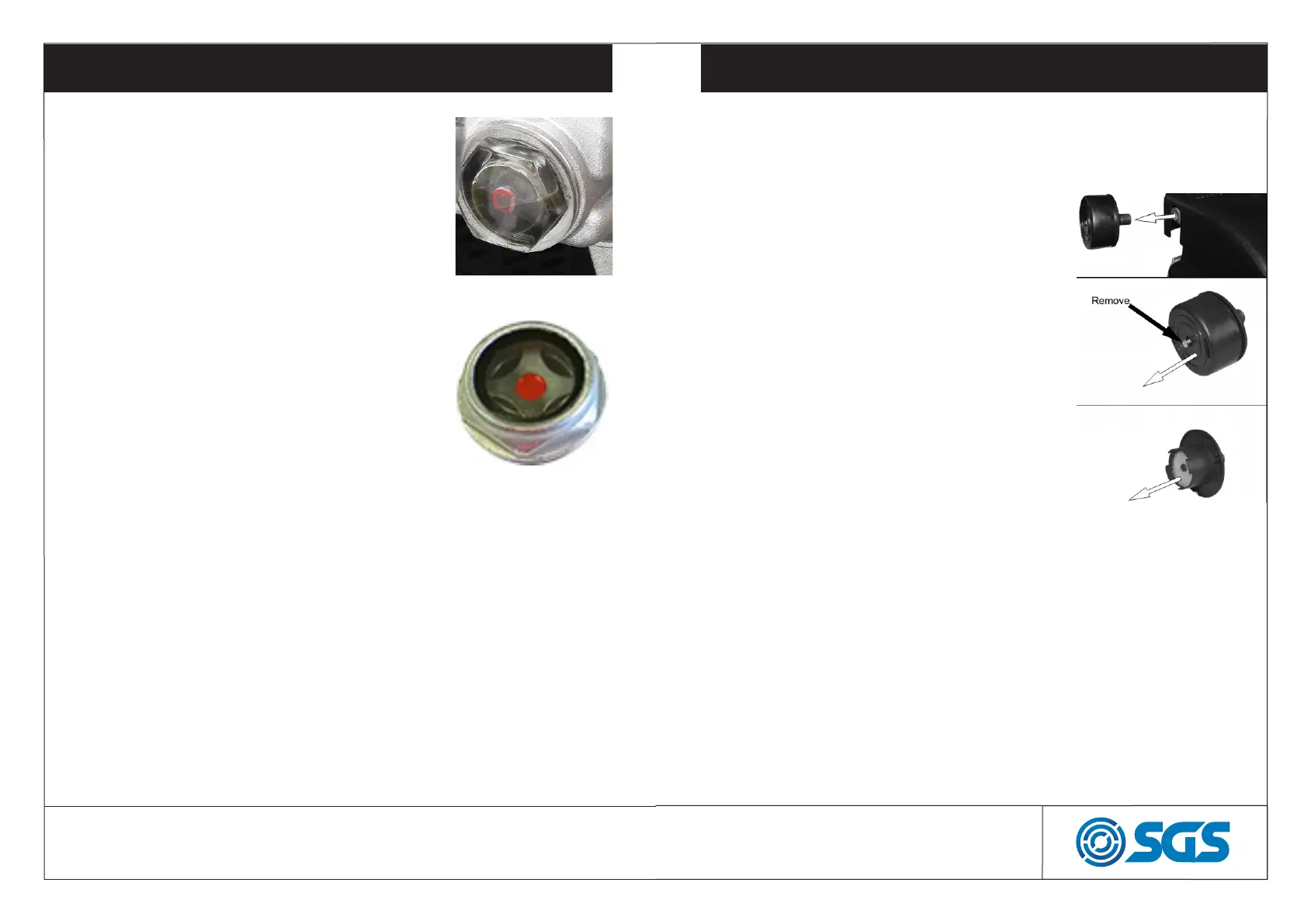

CLEAN THE AIR FILTERS (MONTHLY)

The air filters must be examined

monthly, more often in dusty condi-

tions:

1. Remove the filter covers from the

compressor.

2. Remove the filter covers from the

filters.

3. Remove the filters from the filter

covers.

4. Clean the sponge and both the

filters cover using a soft brush.If

necessary, the filters can be care-

fully cleaned in warm soapy water.

Rinse and let the filters dry com-

pletely before refitting.

5. Make sure that the filters and filter

covers are replaced into position. If

the filters are damaged, you must

WWW.SGS-ENGINEERING.COM

Loading...

Loading...