PAGE 13

PAGE 12

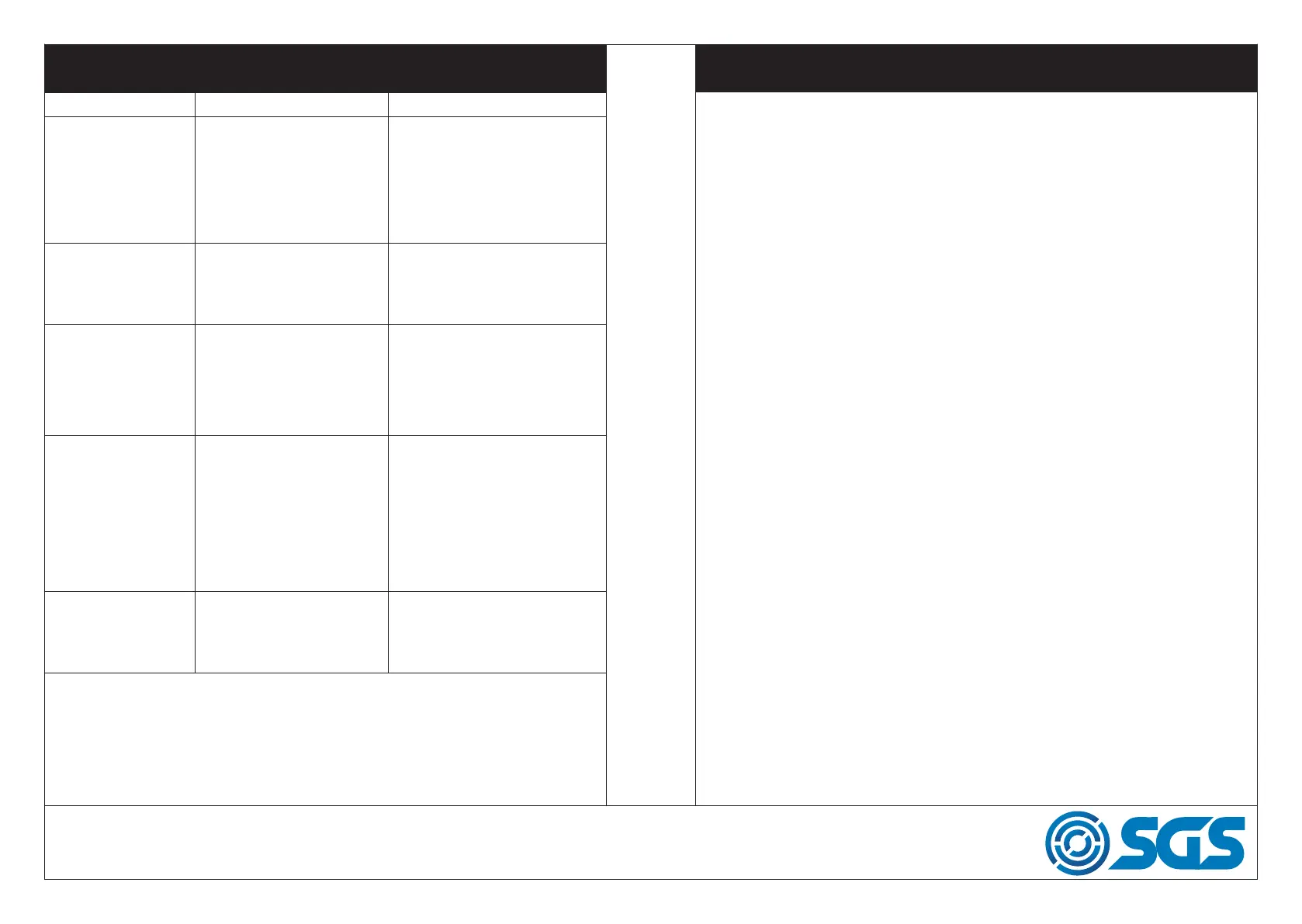

TROUBLESHOOTING

PROBLEM POSSIBLE CAUSE ACTION

Motor unable to run,

running slow or getting

hot

1. Fault in line or insufficient

voltage

2. Power wire too thin or long

3. Fault in pressure switch

4. Fault in motor

5. Sticking of main compres-

sor

1. Check the line

2. Replace the wire

3. Repair or replace

4. Repair or replace

5. Check and repair

Sticking of main com-

pressor

1. Moving parts burnt due to

insufficient oil

2. Moving parts damaged or

stuck by a foreign body

Check crankshaft, bearing,

connecting rod, piston, piston ring,

etc. and replace if

necessary

Shaking or abnormal

noise

1. Connecting part loose

2. Foreign body in the main

compressor

3. Piston knocking the valve

seat

4. Moving parts seriously

worn

1. Check and retighten

2. Check and clean away

3. Replace with thicker paper

gasket

4. Repair or replace

Pressure insufficient

or discharge capacity

decreased

1. Motor running too slow

2. Air filter choked up

3. Leakage of safety valve

4. Leakage of discharge pipe

5. Sealing gasket damaged

6. Valve plate damaged,

stuck or carbon build up

7. Piston ring and cylinder

worn or damaged

1. Check and remedy

2. Clean or replace the cartridge

3. Check and adjust

4. Check and repair

5. Check and replace

6. Replace and clean

7. Repair or replace

Excessive oil consump-

tion

1. Oil level too high

2. Breather pipe choked up

3. Piston ring and cylinder

worn or damaged

1. Keep the level within set range

2. Check and clean

3. Repair or replace

Changing the oil

Switch off the motor and remove the power plug from the socket outlet.

Release any remaining air pressure and then unscrew the oil drain plug

from the compressor pump and remove. Direct the oil into an appropriate

container. If any oil still remains, tilt the compressor slightly. When all the

old oil has been removed, screw the oil drain plug into place.

Cleaning

Clean the items with a soft brush or a wipe moistened with a suitable bio-

degradable solvent. Do not use flammable liquids like petrol or alcohol,

they are a risk and will damage the finish and plastic parts.

Cleaning/ changing the air filter (Monthly)

Please note: This compressor should not be used in a heavily dusty atmos-

phere. The warranty does not cover damage caused by a blocked air filter.

The air filter must be cleaned or replaced monthly, or more frequently if

the compressor is in regular use. The air filter can be accessed easily by

unscrewing the air filter cover (wing nut) at the side of the pump.

MAINTENANCE

WWW.SGS-ENGINEERING.COM

Loading...

Loading...