96-723, 97-715, 97-716, 97-717 • REV. 2/04

11

PRESSURE WASHER

OPERATOR’S MANUAL

This pressure washer was produced with the best available materials and quality craftsmanship. However, you as

the owner have certain responsibilities for the correct care of the equipment. Attention to regular preventative

maintenance procedures will assist in preserving the performance of your equipment. Contact your dealer for

maintenance. Regular preventative maintenance will add many hours to the life of your pressure washer. Perform

maintenance more often under severe conditions.

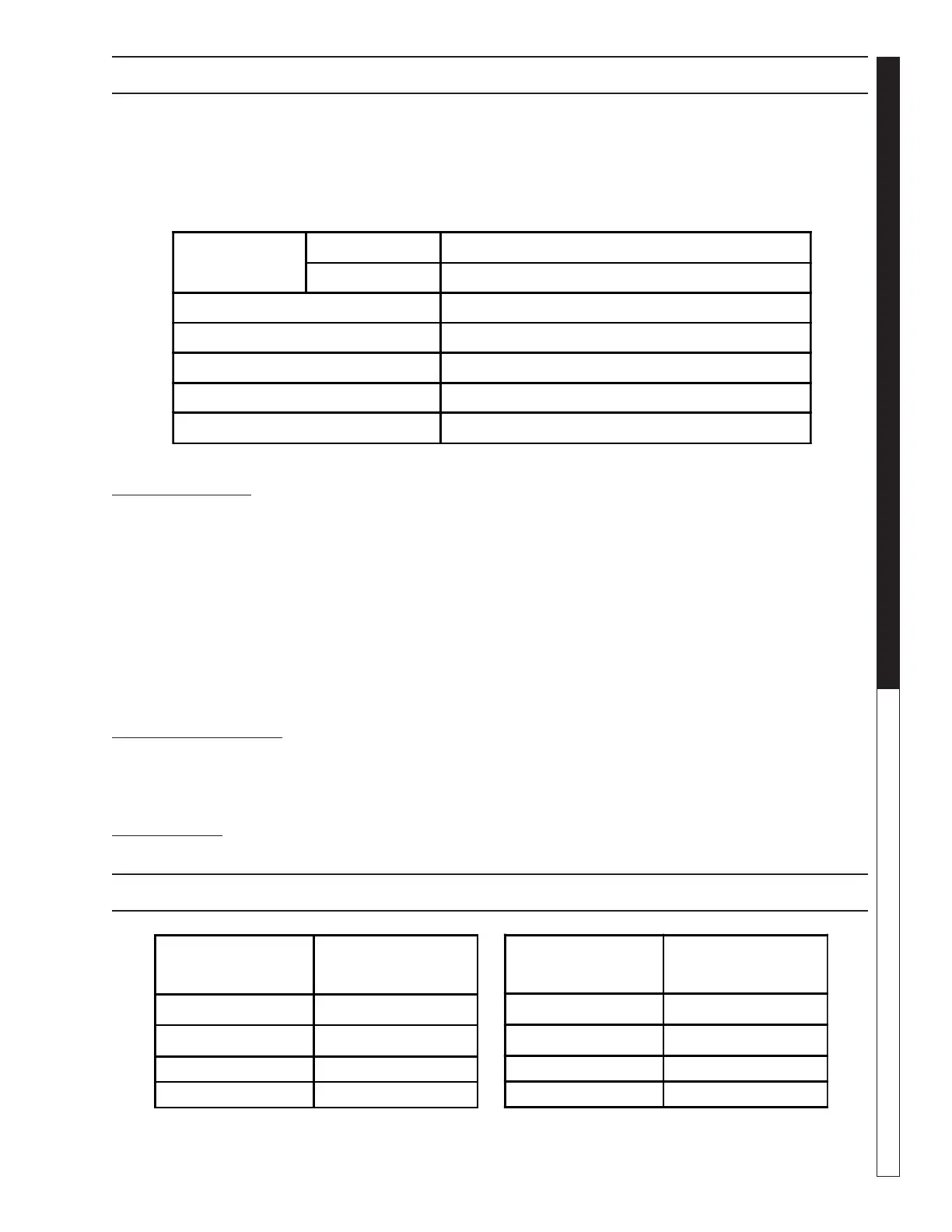

Pump Oil

Inspect Daily inspect the oil level

Change After first 50 hours, then every 500 hours or annually

Replace High Pressure Nozzle Every 6 months

Replace Quick Connects Anually

Clean Water Screen/Filter Weekly

Replace HP Hose Anually if there is any sign of wear

Grease Motor Every 10,000 hours or annually

General Inspection Inspect the motor at regular intervals, approximately every 500 hours of operation,

or every 3 months, whichever occurs first. Keep the motor clean and the ventilation

openings clear. The following steps should be performed at each inspection:

WARNING: Do not touch electrical connections before you first ensure that power

has been disconnected. Electrical shock can cause serious or fatal injury. Only quali-

fied personnel should attempt the installation, operation and maintenance of this

equipment.

1. Check that the motor is clean. Check that the interior and exterior of the motor

is free of dirt, oil, grease, water, etc. Oily vapor, paper pulp, textile lint, etc. can

accumulate and block motor ventilation. If the motor is not properly ventilated

overheating can occur and cause early motor failure.

2. Check all electrical connectors to be sure that they are tight.

Lubrication & Bearings Bearing grease will lose its lubricating ability over time, not suddenly. The lubricating

ability of a grease (over time) depends primarily on the type of grease, the size of the

bearing, the speed at which the bearing operates and the severity of the operating

conditions. Good results can be obtained if the following recommendations are used in

your maintenance program.

Type of Grease A high grade ball or roller bearing grease should be used. Recommended greases

standard service conditions are: Shell Dolium R (Factory installed) or Chevron SRI

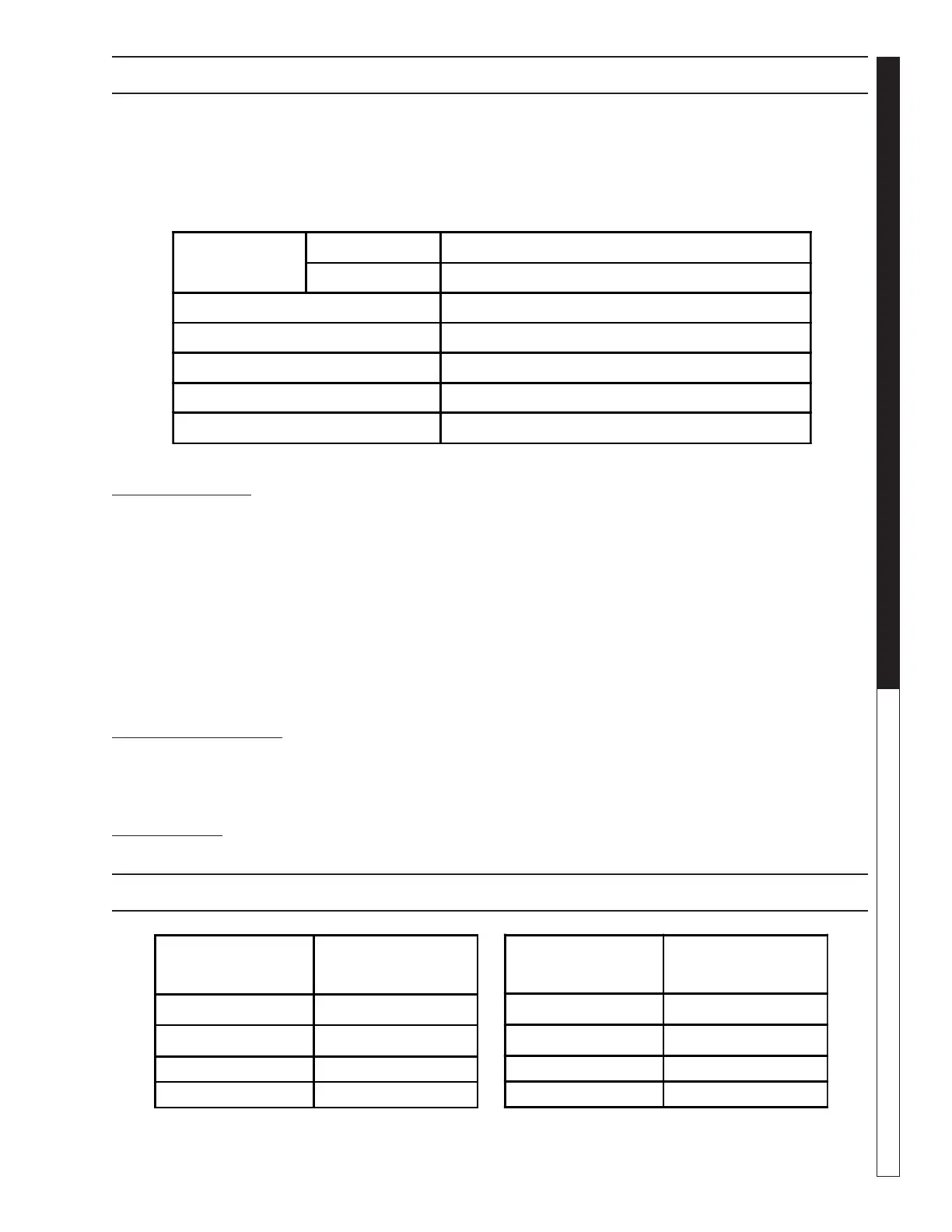

OIL CHANGE RECORD

Date Oil Changed

Month/Day/Year

Estimated Operating

Hours Since Last

Oil Change

Date Oil Changed

Month/Day/Year

Estimated Operating

Hours Since Last

Oil Change

PREVENTATIVE MAINTENANCE

Loading...

Loading...