VL-PD3U

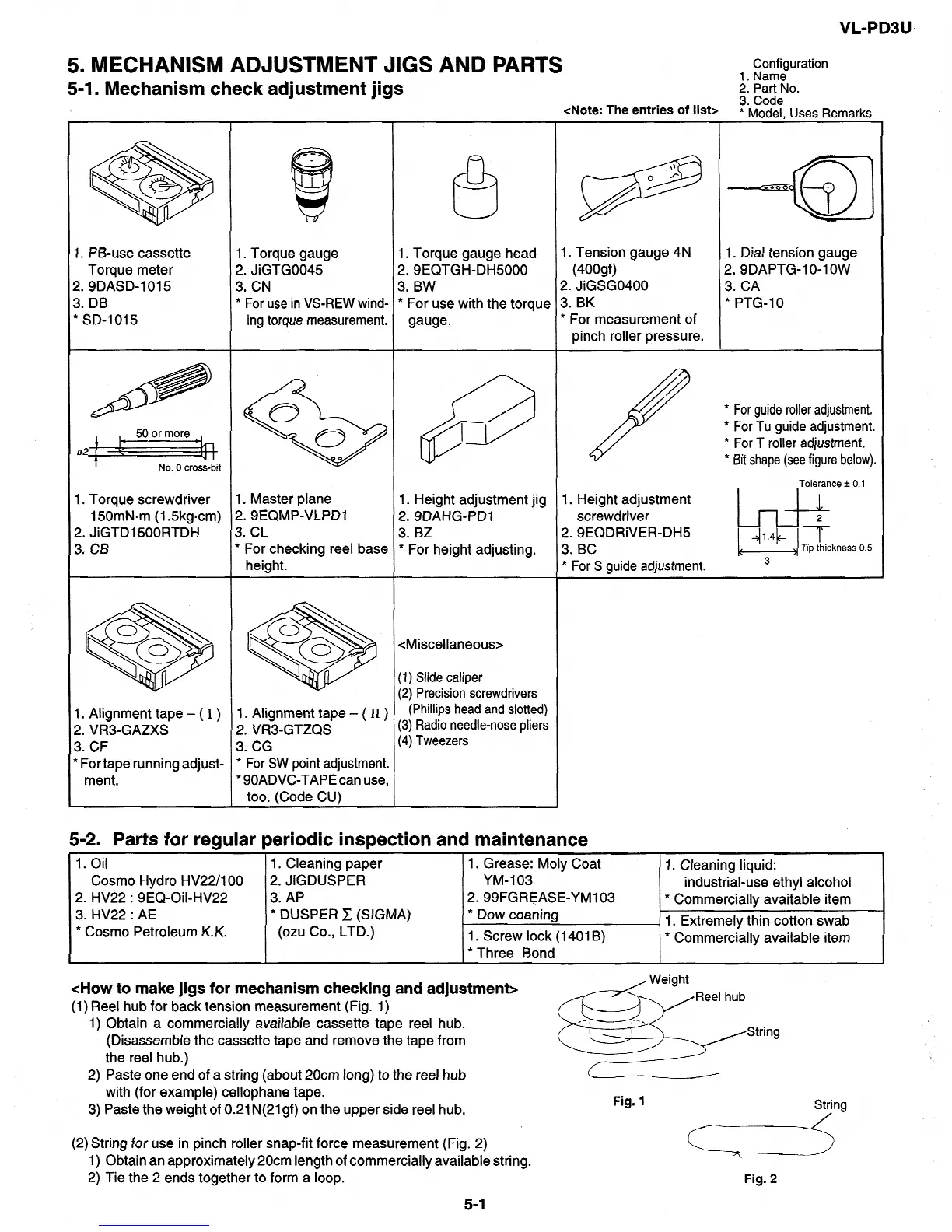

5. MECHANISM ADJUSTMENT JIGS AND PARTS

Configuration

1. Name

5-I. Mechanism check adjustment jigs

2. Part No.

<Note: The entries of list>

3. Code

*

Model, Uses

Remarks

I. PB-use cassette

Torque meter

2. SDASD-1015

3. DB

’

SD-1 015

. . 50

or

more

,

No. 0 cross-bit

1. Torque screwdriver

150mN*m (15kgcm)

2. JiGTDl SOORTDH

3. CB

1. Alignment tape -

( I )

1. Alignment tape -

( II )

2. VR3-GAZXS

2. VR3-GTZQS

3. CF

3. CG

* For tape running adjust-

ment.

* For SW point adjustment,

* SOADVC-TAPE can use,

too. (Code CU)

1. Torque gauge

2. JiGTG0045

3. CN

k For use in VS-REW wind-

ing torque measurement.

1. Master plane

2. SEQMP-VLPDI

3. CL

’ For checking reel base

height.

1. Torque gauge head

2.9EQTGH-DH5000

3. BW

* For

use with the torque

gauge.

6fi@

I

1. Height adjustment jig

2. SDAHG-PDI

3. BZ

* For height adjusting.

<Miscellaneous>

(1) Slide caliper

(2)

Precision screwdrivers

(Phillips head and slotted)

(3) Radio needle-nose pliers

(4) Tweezers

\\

0

p

z

I. Tension gauge 4N

(400gf)

1. JiGSG0400

3. BK

’

For measurement

of

pinch roller pressure.

1. Height adjustment

screwdriver

2.9EQDRiVER-DH5

3. BC

* For S guide adjustment.

--@J

1. Dial tension gauge

2.

9DAPTG-1

O-l OW

3. CA

* PTG-10

* For guide roller

adjustment.

*

For

Tu guide adjustment.

* For T roller adjustment.

* Bit shape (see figure below).

Tolerance f 0.1

5-2. Parts for regular periodic inspection and maintenance

1. Oil

Cosmo Hydro HV22/100

2. HV22

: 9EQ-Oil-HV22

3. HV22

:

AE

* Cosmo Petroleum K.K.

1. Cleaning paper

2. JiGDUSPER

3. AP

* DUSPER C (SIGMA)

(ozu Co., LTD.)

1. Grease: Moly Coat

YM-103

2.99FGREASE-YM103

* Dow coaning

1. Screw lock (1401 B)

* Three Bond

1. Cleaning liquid:

industrial-use ethyl alcohol

* Commercially avaitable item

. 1. Extremely thin cotton swab

* Commercially available item

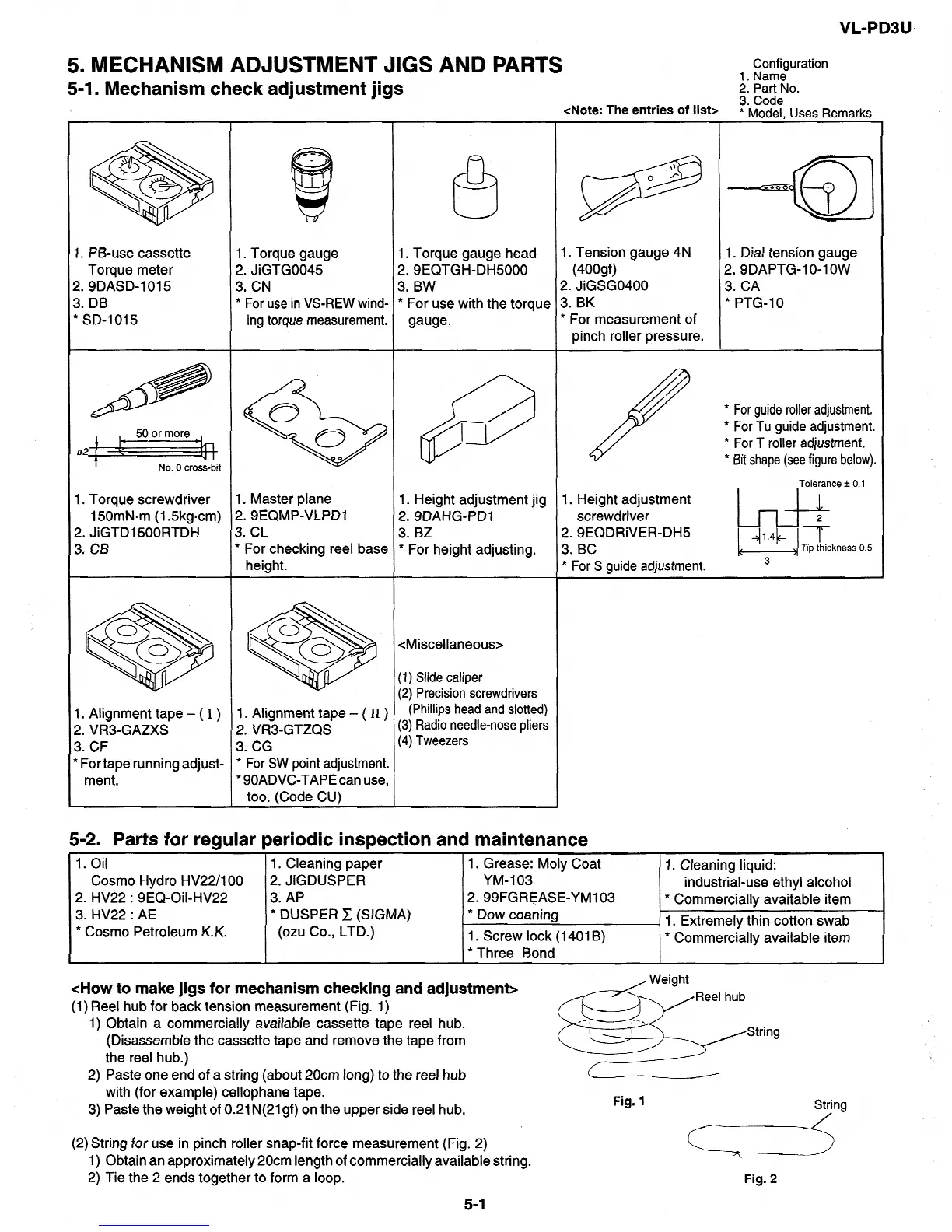

CHOW to make jigs for mechanism checking and adjustment>

[I) Reel hub for back tension measurement (Fig. 1)

1) Obtain a commercially available cassette tape reel hub.

(Disassemble the cassette tape and remove the tape from

the reel hub.)

2) Paste one end of a string (about 20cm long) to the reel hub

with (for example) cellophane tape.

Weight

Reel hub

_-

I I -_

String

v

3) Paste the weight of 0.21 N(21gf) on the upper side reel hub.

(2) String for use in pinch roller snap-fit force measurement (Fig. 2)

1) Obtain an approximately 20cm length of commercially available string.

2) Tie the 2 ends together to form a loop.

Fig. 1

String

:rl__j

-

Fig. z!

51

I

Loading...

Loading...