‐8‐

.9.

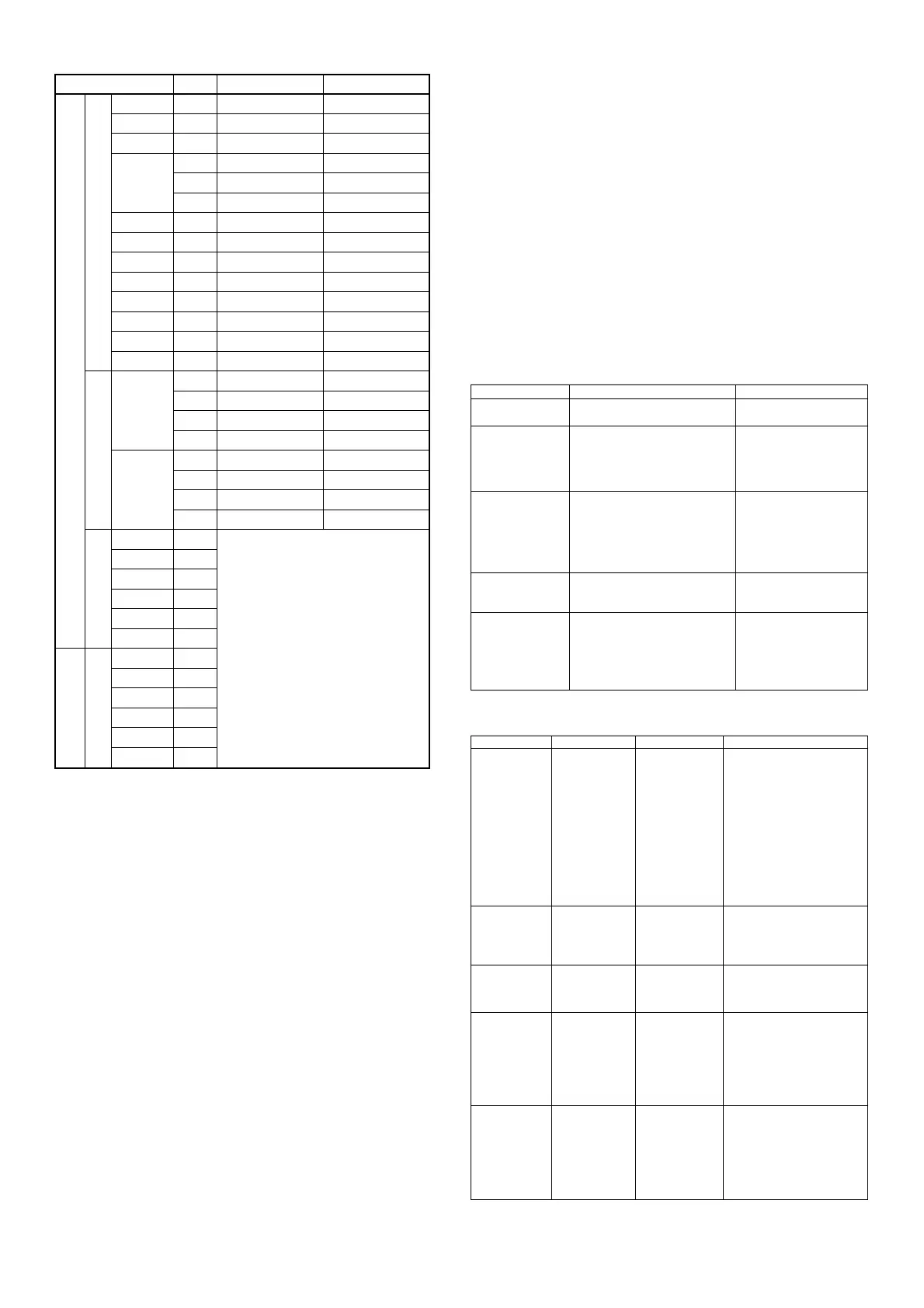

Table of Measuring Range Codes

Input type

Code

Measuring range

(°C)

Measuring range

(°F)

Multi

Thermocouple

B

*1

01

0.0 - 1800.0

0.0 - 3300.0

R

02

0.0 - 1700.0

0.0 - 3100.0

S

03

0.0 - 1700.0

0.0 - 3100.0

K

04

−199.9 - 400.0

−300.0 - 750.0

05

0.0 - 800.0

0.0 - 1500.0

06

0.0 - 1200.0

0.0 - 2200.0

E

07

0.0 - 700.0

0.0 - 1300.0

J

08

0.0 - 600.0

0.0 - 1100.0

T

09 *2

−199.9 - 200.0

−300.0 - 400.0

N

10

0.0 - 1300.0

0.0 - 2300.0

PLII

*3

11

0.0 - 1300.0

0.0 - 2300.0

WRe5-26

*4

12

0.0 - 2300.0

0.0 - 4200.0

U

*5

13 *2

−199.9 - 200.0

−300.0 - 400.0

L

*5

14

0.0 - 600.0

0.0 - 1100.0

R.T.D.

Pt100

31

−200.0 - 600.0

−300.0 - 1100.0

32

−100.0 - 100.0

−150.0 - 200.0

33

−50.0 - 50.0

−50.0 - 120.0

34

0.0 - 200.0

0.0 - 400.0

JPt100

35

−200.0 - 500.0

−300.0 - 1000.0

36

−100.0 - 100.0

−150.0 - 200.0

37

−50.0 - 50.0

−50.0 - 120.0

38

0.0 - 200.0

0.0 - 400.0

mV

−10 - 10

71

Initial value: 0.0 - 100.0

Span: 10 - 5000 digit

Position of decimal point: None

1, 2 or 3 digits on the right of decimal point

Lower limit value < Higher limit value

0 - 10

72

0 - 20

73

0 - 50

74

10 - 50

75

0 -100

76

Voltage

V

−1 - 1

81

0 - 1

82

0 - 2

83

0 - 5

84

1 - 5

85

1 - 10

86

Thermocouple B, R, S, K, E, J, T, N: JIS/IEC

R.T.D. Pt100: JIS/IEC JPt100/Former JIS

*1 Thermocouple B: Accuracy guarantee not applicable to

400˚C (752˚F) and below.

*2 Thermocouple Thermocouple is K, T, U and indicates ±

(0.5%FS+1 digit) when accuracy is 0

-

100˚C and ± (1.0%FS+1 digit) when

accuracy is below 100˚C.

*3 Thermo

couple

PLII Platinel

*4 Thermo

couple

WRe5-26 (ASTM988)

*5 Thermo

couple

U, L (DIN 43710)

Note: Unless otherwise specified, the measuring ranges are K thermocouple

0.0-800.0˚C for multi input and 0-10VDC: 0.0 - 100.0 for voltage (V)

input at the time of shipment from the factory.

Note: Do not use the above sensors (current/voltage, thermocouple, R.T.D.)

for the measurement of power supply line.

10. Maintenance and Troubleshooting

10-1. Procedure of Maintenance Replacement and Matters

Be attended to (Steps for replacing defective items)

Confirmation of Model Code:

Check the model code of the component part in trouble.

(Open the control box, and you can find an appropriate code in the

model label affixed to the instrument case.)

Inquiry on Input Data:

Ask the manufacturer if input data (control date of external

operation, event output, set value of position, etc. at the time when

an error occurs) is necessary or not.

Confirmation of Present Wiring Condition:

Check and record the present wiring condition. Please note that in

case input data is necessary for control, the same control operation

as before is not possible with a replaced product unless such data

is input.

Confirmation of Present Input Data:

When data is not known, call the input date for the product, check

and record it. In case input data is required, the same control

operation as before is not with a replaced product unless such data

is input.

Repair of Present Product or Procurement of New Product:

In case the product in trouble is removable from the site of

installation, remove and have it repaired. If it is not possible,

arrange to acquire a new product for replacement.

Setting before Starting Operation:

When replaced by a new product, check the wiring, apply power

and set items as described in 8. Before Starting Up.

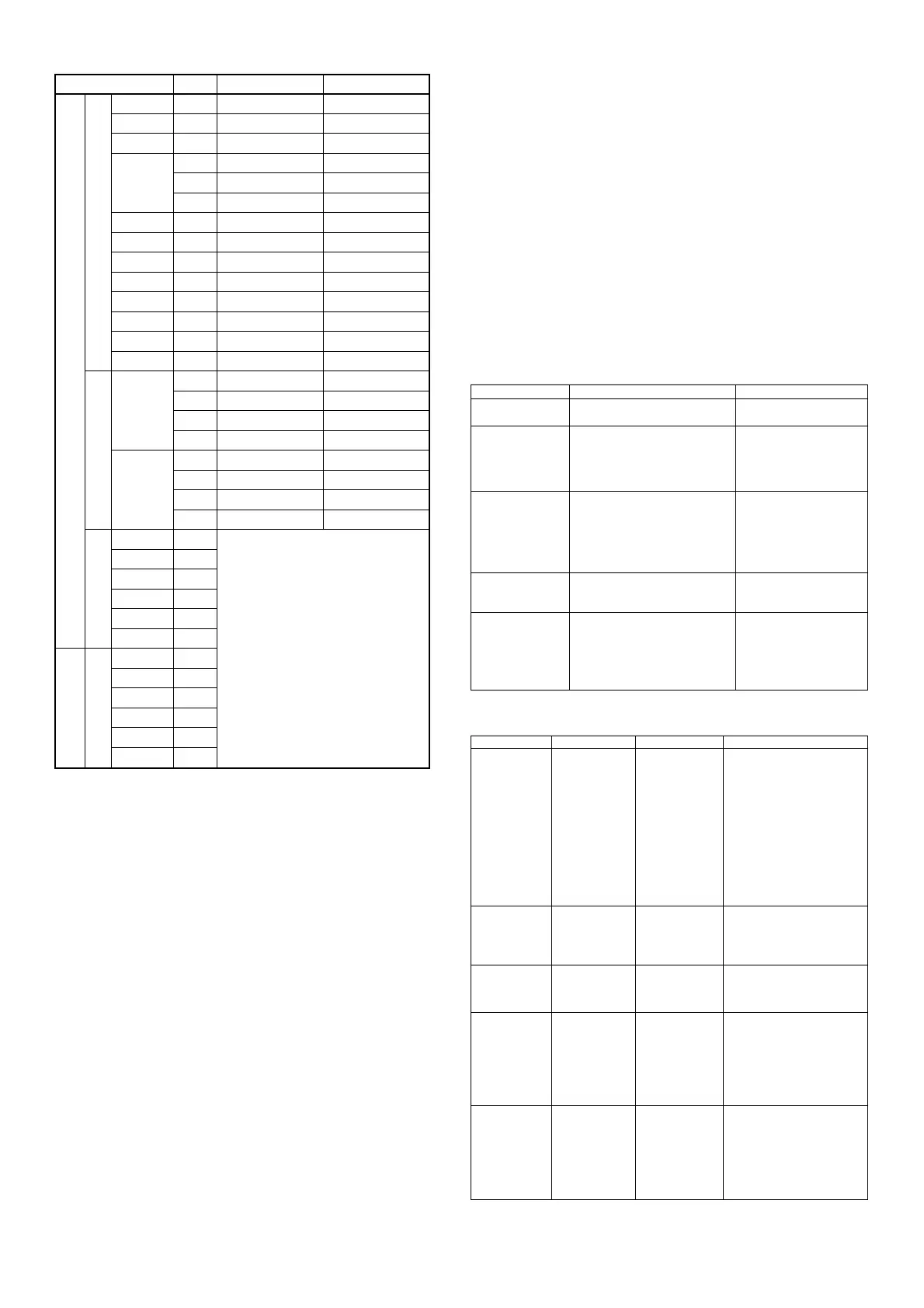

10-2. Cause of Trouble and Troubleshooting

Problem Cause Remedy

Error code is

displayed.

Refer to "Error Codes, Causes

and Remedies."

Refer to "Error Codes,

Causes and Remedies."

Displayed PV

value seems

to be incorrect.

Set measuring range code is

different from that of input

sensor/input signal.

Erroneous wiring to input

terminals of sensor

Check if set measuring

range code is correct

for input signal.

Correct wiring to input

terminals of sensor.

Display on the

front panel

goes out and

the instrument

does not

operate.

Problem with power supply

and wiring

Deterioration of the

connection product.

Inspect portions related

to power source and

wire connection.

Check wiring.

Examine the product

and repair or replace.

Key unable to

be operated.

Keylock is in effect.

Deterioration of the product.

Release keylock.

Examine and repair or

replace the product.

ON-OFF action

of control

output is too

fast.

ON-OFF is set for P of PID.

Too small a value set for

hysteresis of ON-OFF action.

Change the OFF set for

P to two-position type

ON-OFF action.

Increase the hysteresis

value of ON-OFF

action.

10-3. Error Codes, Causes and Remedies

(Inputmeasuredvalueproblems)

Screen display Problem Cause Remedy

(HHHH)

Higher limit side

scale over

A break of

thermocouple

input wiring

A break of

R.T.D. input

wiring

Input

measured

value

exceeded

measuring

range higher

limit of by 10%.

Check thermocouple input

wiring for a possible break.

Check R.T.D. input A wiring

for a possible break. If

wiring has no problem,

replace R.T.D.

For voltage or current input,

check the transmitting unit

of measured values.

Check if set code of

measuring range is correct for

input signal.

(LLLL)

Lower limit side

scale over

Input measured

value fell from

lower limit of

measuring range

by 10%.

Check wiring of inversed

polarity for measured value

input.

(b----)

A break of

R.T.D. input

wiring.

A break of B

Breaks of ABB

Check R.T.D. input terminals

A, B and B for breaks. If

wiring has no problem,

replace R.T.D.

(CJHH)

Higher limit side

scale over of

cold junction

(CJ) of

thermocouple

input.

Ambient

temperature of the

product has

exceeded 80°C.

Reduce ambient

temperature to the level

provided in the environment

conditions for the product.

In case ambient

temperature has not

exceeded 80°C, examine

the product.

(CJLL)

Lower limit side

scaleover of cold

junction (CJ) of

thermocouple

input.

Ambient

temperature of the

product has fallen

to 20°C or lower.

Raise ambient temperature

to the level provided in the

environment conditions for

the product.

In case ambient

temperature has not fallen

to 20°C, examine the

product.

Loading...

Loading...