NOTI143US - R00.doc Translation of the original instructions 14/25

4.

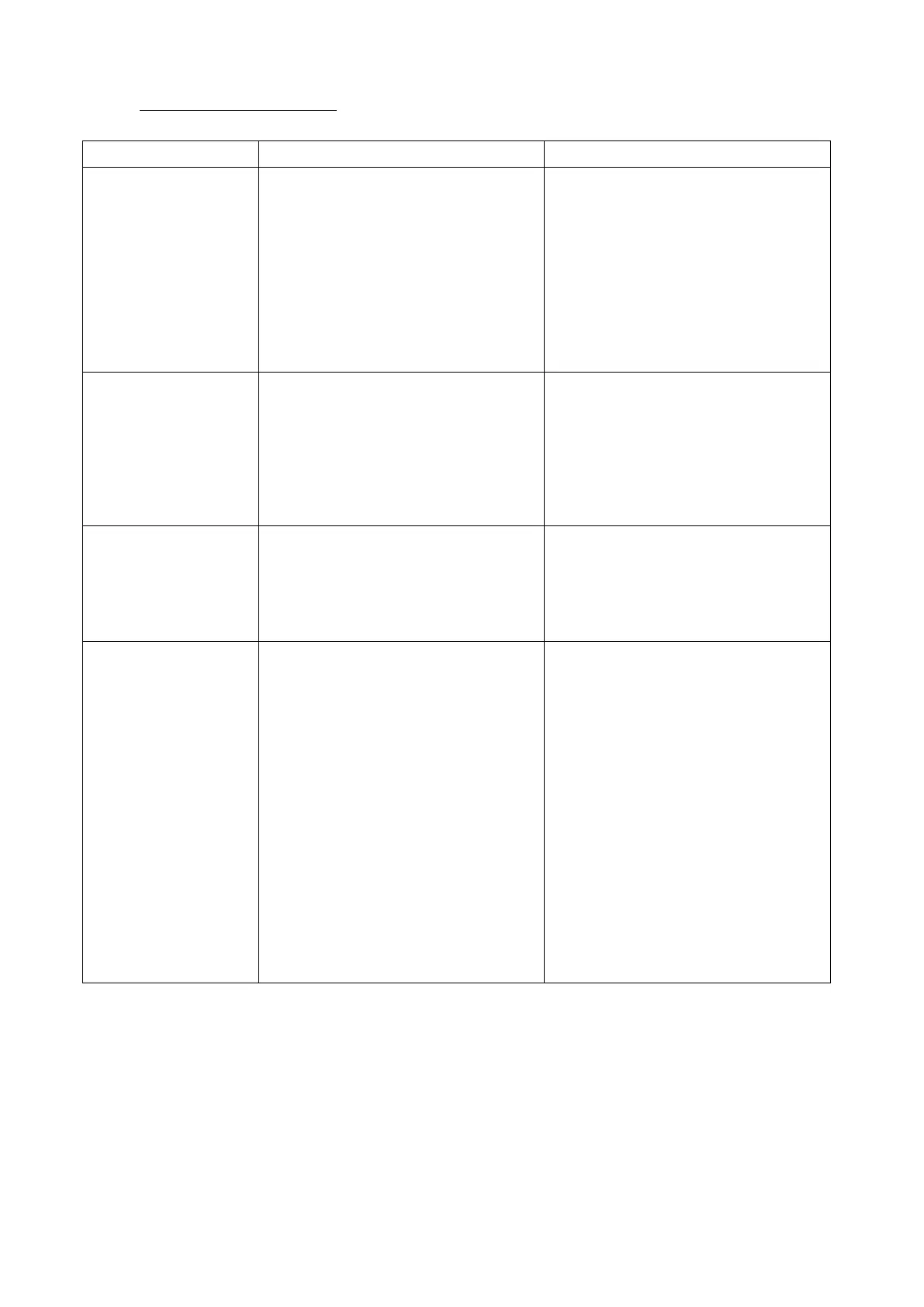

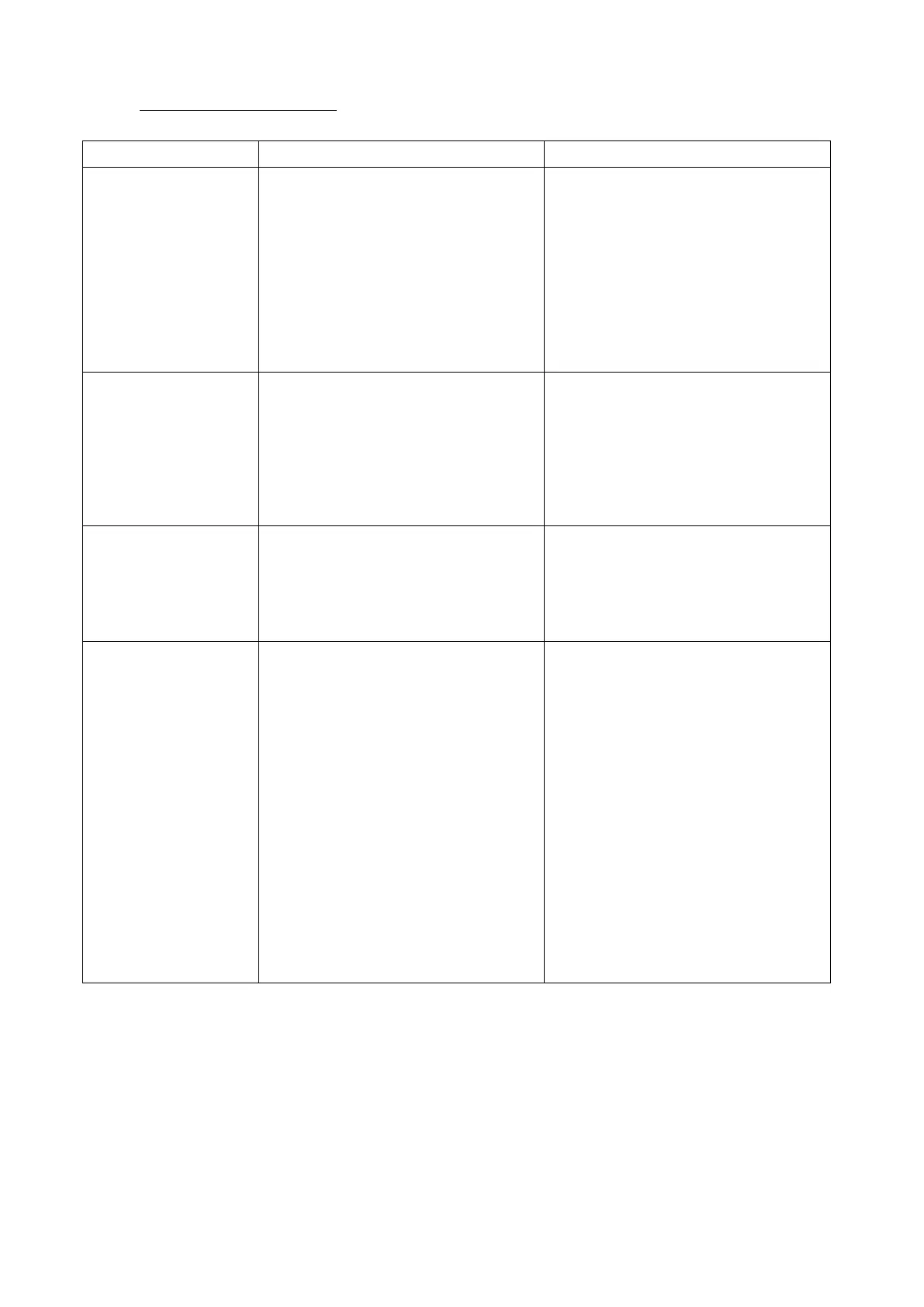

TROUBLE SHOOTING

The stylus assembly does not

move on the X and Y axes

Check that :

- The controller is on

- A marking program is loaded and the controller

is in marking mode (see software manual)

- The machine is correctly linked to the controller

- The cable is in working condition

- The control handbox is connected (except for

gun marking machines)

- The movements on the X and Y axes are not

blocked when the machine is on.

- See controller manual

- Load a program and set the machine in marking

mode

- Reposition the connectors

- Open the connectors and check the wires either

visually or with a ohmmeter.

- Reposition the connectors

- Remove any obstacle or clean the guiding rails

and the driving mechanisms

The marking head does not go

back home before marking

Check that :

- The sensors cables are correctly connected and

in good working condition

- The origin sensors work properly (in home

position, the red lights located on the sensors

are off, otherwise they are on).

- The driving belts are not broken on the

integrated type or column type machines

- Reconnect the wires or replace the damaged

cables

- Replace the sensors

- Replace the damaged belt

The stylus assembly moves

(X,Y) but the stylus does not

Check that :

- The stylus is not blocked by anything

- The solenoid is in good working condition (no

overheating, short circuit…)

- Disassemble the machine, clean it, lubricate it

with the oil provided in your maintenance kit and

re-assemble (see General layout in appendix)

- Replace the solenoid

The marking quality is terrible :

- The dots are not aligned

- The impacts are not

regular

Check that :

- The part is correctly maintained during the entire

marking process and the machine is correctly

fastened

- The marking speed is not too high compared

with the marking to be made (size)

- There is no backlash in the X and Y axes

- The distance between the stylus and the part is

correct

- The stylus pin is in good working condition

- The stylus can move correctly

- There is no backlash between the stylus pin

guide and the stylus

- Redo the marking after fastening the part and/or

the machine properly

- Reduce the marking speed

- Please contact the after sales service

- Change the distance (see manual)

- Replace the stylus

- Clean the stylus pin guide and the stylus

- Change the stylus pin guide

If you have checked everything and the system still does not work, please contact our

after sales services.

Loading...

Loading...