68/80

Siemens Building Technologies Commissioning Guide CM1G5192en

HVAC Products 10 Parameterization 26.02.2003

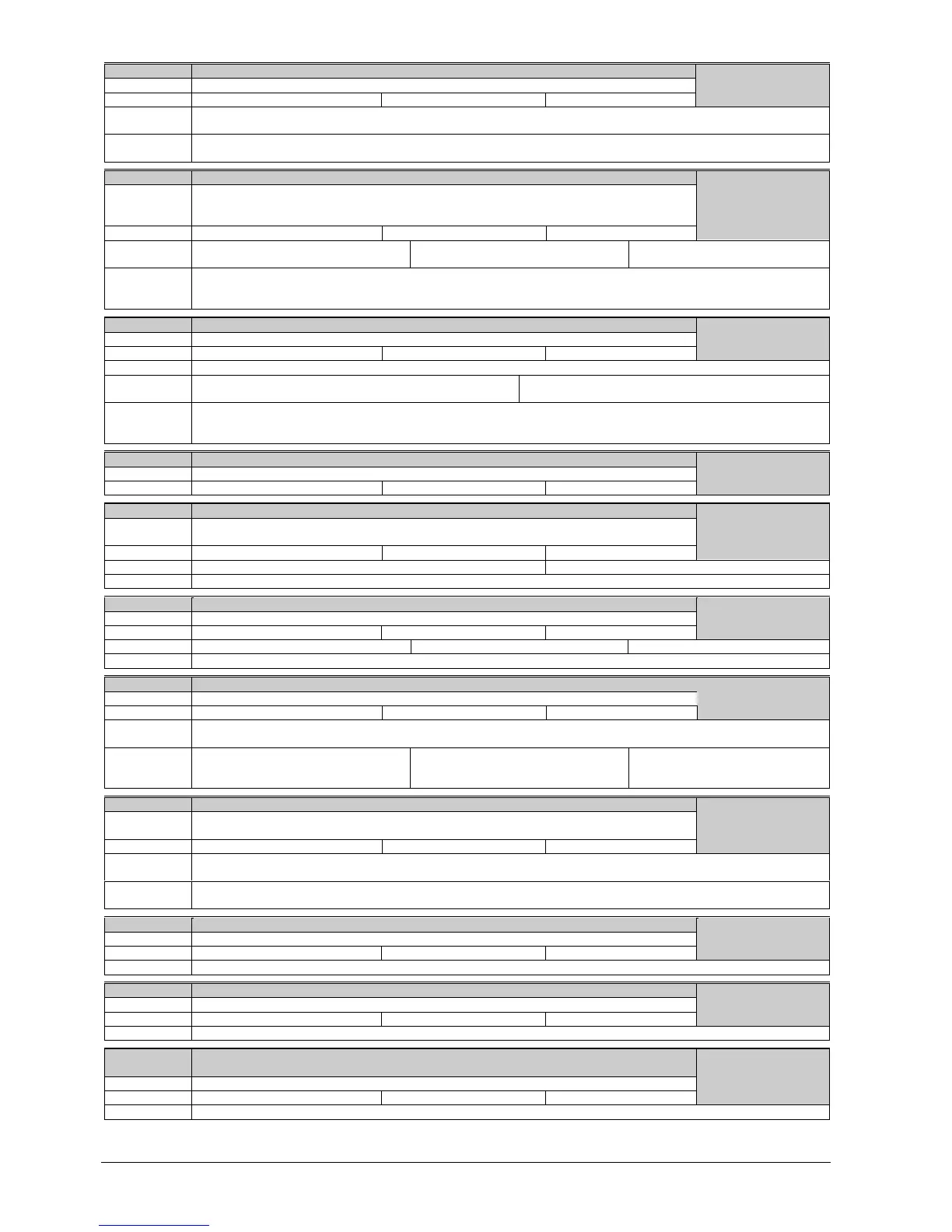

P2100[3] Alarm number selection

Selects up to 3 faults or warnings for non-default reactions

Unit: - Min: 0 Def: 0 Max: 65535

Level 3

Example:

If you want F0005 to perform an OFF3 instead of an OFF2, set P2100[0]=5, then select the desired response in

P2101[0] (in this case, set P2101[0]=3)

Note:

All fault codes have a default response to OFF2. Some fault codes caused by hardware trips (e.g. overcurrent) cannot

be changed from the default responses

P2101[3] Stop reaction value

Sets VSD stop reaction values for fault selected by P2100 (alarm number stop reaction).

This indexed parameter specifies the special response to the faults / warnings defined in

P2100 indices 0 to 2

Unit: - Min: 0 Def: 0 Max: 5

Level 3

Settings:

0=No reaction, no display

1=OFF1 stop reaction

2=OFF2 stop reaction

3=OFF3 stop reaction

4=No reaction warning only

5=Goto fixed frequency 15

Note:

Settings 0 - 3 are only available for fault codes

Settings 0 and 4 are only available for warnings

Index 0 (P2101) refers to fault / warning in index 0 (P2100)

r2110[4] Warning number

Displays warning information

Unit: - Min: - Def: - Max: -

Level 3

Details

A maximum of 2 active warnings (indices 0 and 1) and 2 historical warnings (indices 2 and 3) may be viewed

Index:

r2110[0]: Recent Warnings --, warning 1

r2110[1]: Recent Warnings --, warning 2

r2110[2]: Recent Warnings -1, warning 3

r2110[3]: Recent Warnings -1, warning 4

Note:

The keypad will flash while a warning is active. The LEDs indicate the warning status in this case

If an AOP is in use, the display will show number and text of the active warning

Indices 0 and 1 are not stored

P2111 Total number of warnings

Displays number of warning (up to 4) since last reset. Set to 0 to reset the warning history

Unit: - Min: 0 Def: 0 Max: 4

Level 3

r2114[2] Run time counter

Displays run time counter. It is the total time the VSD has been powered up. Every time you do

power cycle, it will save the value; then, restore it and the counter carries on ticking

Unit: - Min: - Def: - Max: -

Level 3

Settings:

r2114[0]: = System time, seconds, upper word r2114[1]: = System time, seconds, lower word

Details:

See r0948 (fault time)

P2115[3] AOP real time clock

Displays AOP real time

Unit: - Min: 0 Def: 0 Max: 65535

Level 3

Index:

P2115[0]: real time, seconds+minutes P2115[1]: real time, hours+days P2115[2]: real time, month+year

Details:

See r0948 (fault time)

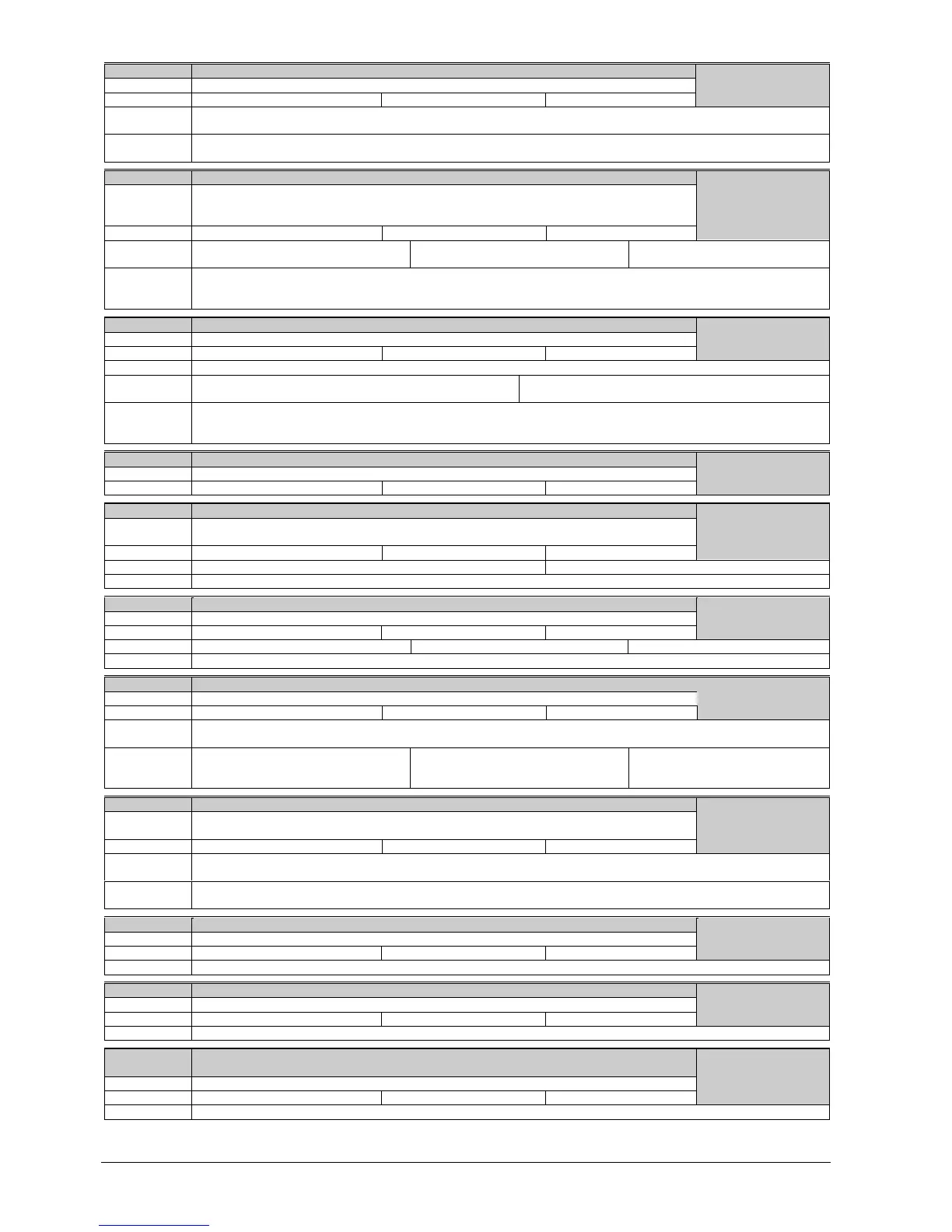

P2181 Belt failure detection mode

Sets belt failure detection mode.

Unit: - Min: 0 Def: 0 Max: 6

Level 3

Details:

This function allows detection of mechanical failure of the drive train, e.g. a broken drive belt. It can also detect condi-

tions which cause an overload, such as a jam.

Settings:

0=Belt failure detection disabled

1=Warn low torque / speed

2=Warn high torque / speed

3=Warn high / low torque / speed

4=Trip low torque / speed

5=Trip high torque / speed

6=Trip high / low torque / speed

P2182 Belt threshold frequency 1

Sets a frequency threshold F1 for comparing actual torque to torque the envelope for belt

failure detection

Unit: Hz Min: 0.00 Def: 5.00 Max: 650.00

Level 3

Details:

The frequency torque envelope is defined by 9 parameters - 3 are frequency parameters (P2182 - P2184), and the other

6 define the low and high torque limits (P2185 - P2190) for each frequency

Note:

The torque is unlimited below P2182, and above P2184. Normally P2182 <= lower torque limit (P1521), and P2184

>=upper torque limit (P1520)

P2183 Belt threshold frequency 2

Sets a threshold F2 for comparing actual torque to torque the envelope for belt failure detection

Unit: Hz Min: 0.00 Def: 30.00 Max: 650.00

Level 3

Note:

See P2182 (belt threshold frequency 1)

P2184 Belt threshold frequency 3

Sets a threshold F3 for comparing actual torque to torque the envelope for belt failure detection

Unit: Hz Min: 0.00 Def: 50.00 Max: 650.00

Level 3

Note:

See P2182 (belt threshold frequency 1)

P2185,

P2187, P2189

Upper torque threshold 1, 2, and 3

Upper limit threshold value for comparing the actual torque

Unit: Nm Min: 0.0 Def: 99999.0 Max: 99999.0

Level 3

Note:

See P2182 (belt threshold frequency 1)

Loading...

Loading...