Motor Components (Options)

Thermal motor protection

1FT6 Synchronous Motors

4-4 Configuration Manual, (PFT6), 10.2005 Edition, 6SN1197-0AD02-0BP1

4.3 Thermal motor protection

A temperature-dependent resistor is integrated as temperature sensor to monitor the motor

temperature.

The resistance of the KTY 84 thermistor changes proportionally to the winding temperature

change.

The temperature signal is sensed and evaluated in the drive converter whose closed-loop

control takes into account the temperature characteristic of the motor resistances.

When a fault occurs, an appropriate message is output at the drive converter. When the motor

temperature increases, a message "Alarm motor overtemperature" is output; this must be

externally evaluated. If this signal is not observed, the drive converter shuts down with the

appropriate fault message when the motor limiting temperature or the shutdown temperature

is exceeded.

The temperature sensor is designed so that the DIN/EN requirement for "protective separa-

tion" is fulfilled.

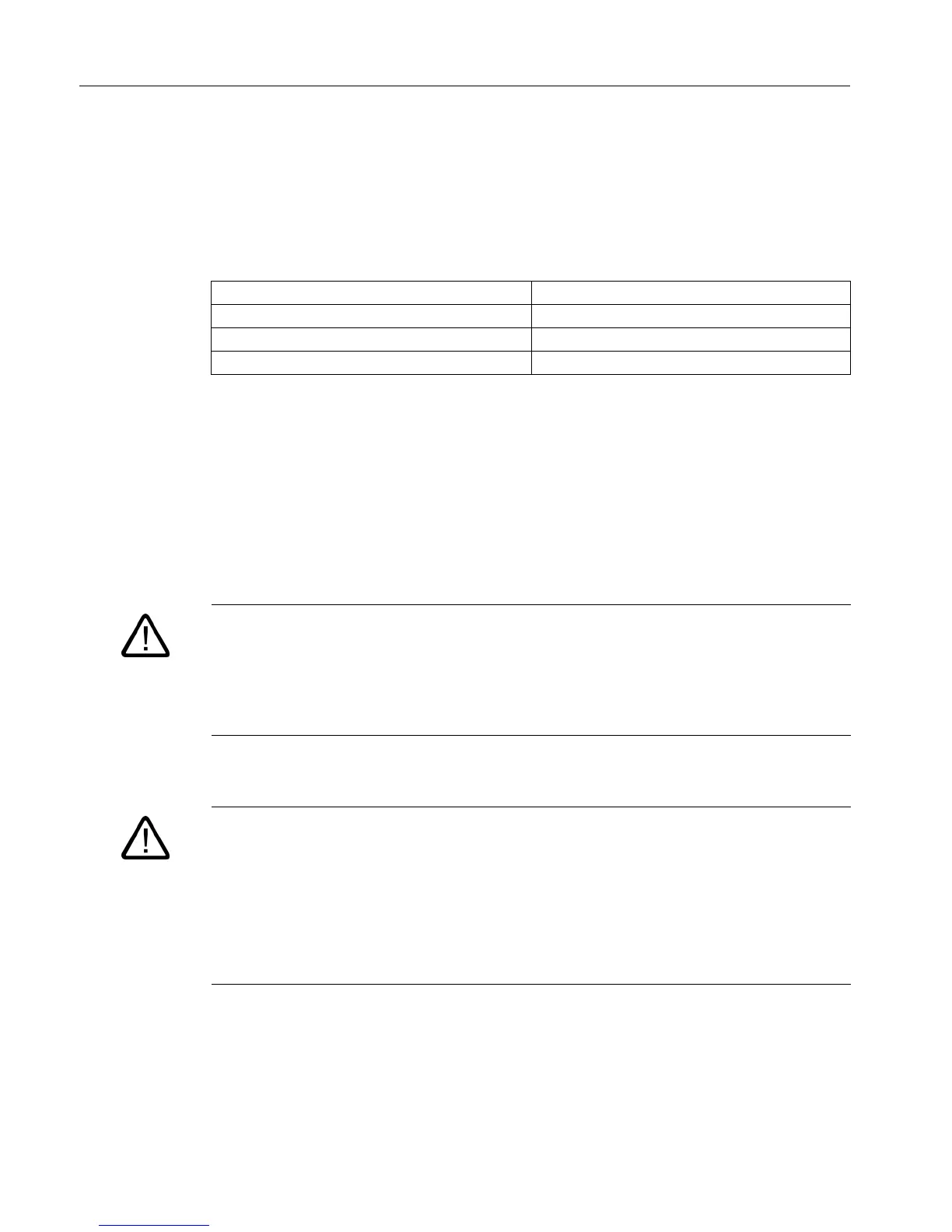

Table 4-3 Features and technical data

Type KTY 84

Resistance when cold (20°C) Approx. 580 Ohm

Resistance when hot (100°C) Approx. 1000 Ohm

Connection Via signal cable

Warning

If the user carries out an additional high-voltage test, then the ends of the temperature sensor

cables must be short-circuited before the test is carried out!

If the test voltage is connected to a temperature sensor terminal, then it will be destroyed.

The polarity must be carefully observed.

Caution

The integrated temperature sensor protects the synchronous against an overload condition

Shaft height 28 to 48 to 2

• I

0 60 K

and speed <> 0

from shaft height 63 up to 4

• I

0 60K

and speed <> 0

For load applications that are critical from a thermal perspective - e.g. overload when the

motor is stationary or an overload of M

max

longer than 4 s, adequate protection is no longer

available.

Loading...

Loading...