VS

07.94

1-104

Siemens AG 1997 All Rights reserved

SIMODRIVE 611A Installation and Start–Up Guide/IAA/–04.97 Edition

The following supplementary functions can be set by mounting wired compo-

nents onto the basic board. (from Order No. 6SN1118–0AD11–0AA1 (1 axis)

and from Order No. 6SN1118–0AE11–0AA1 (2 axis) .

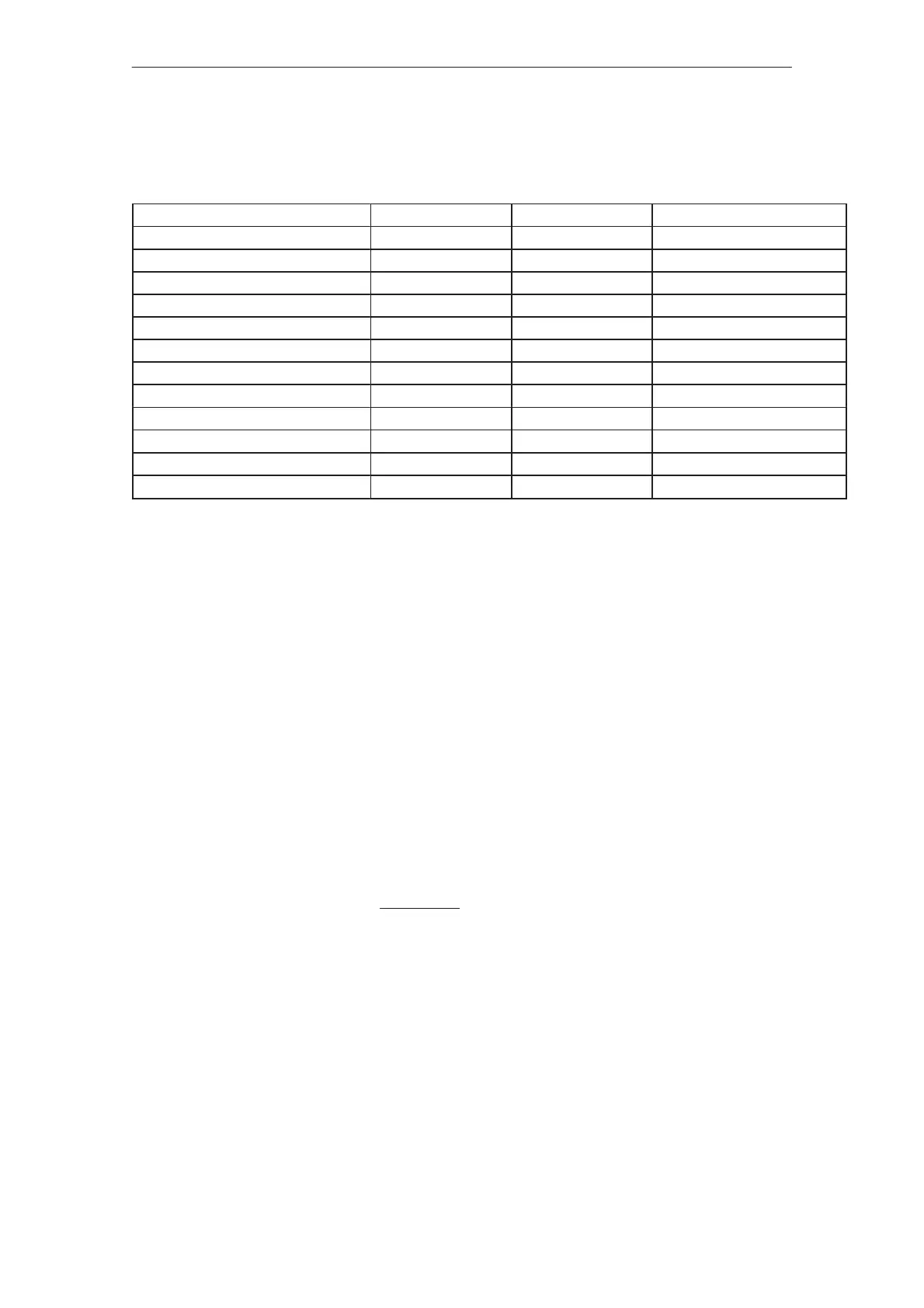

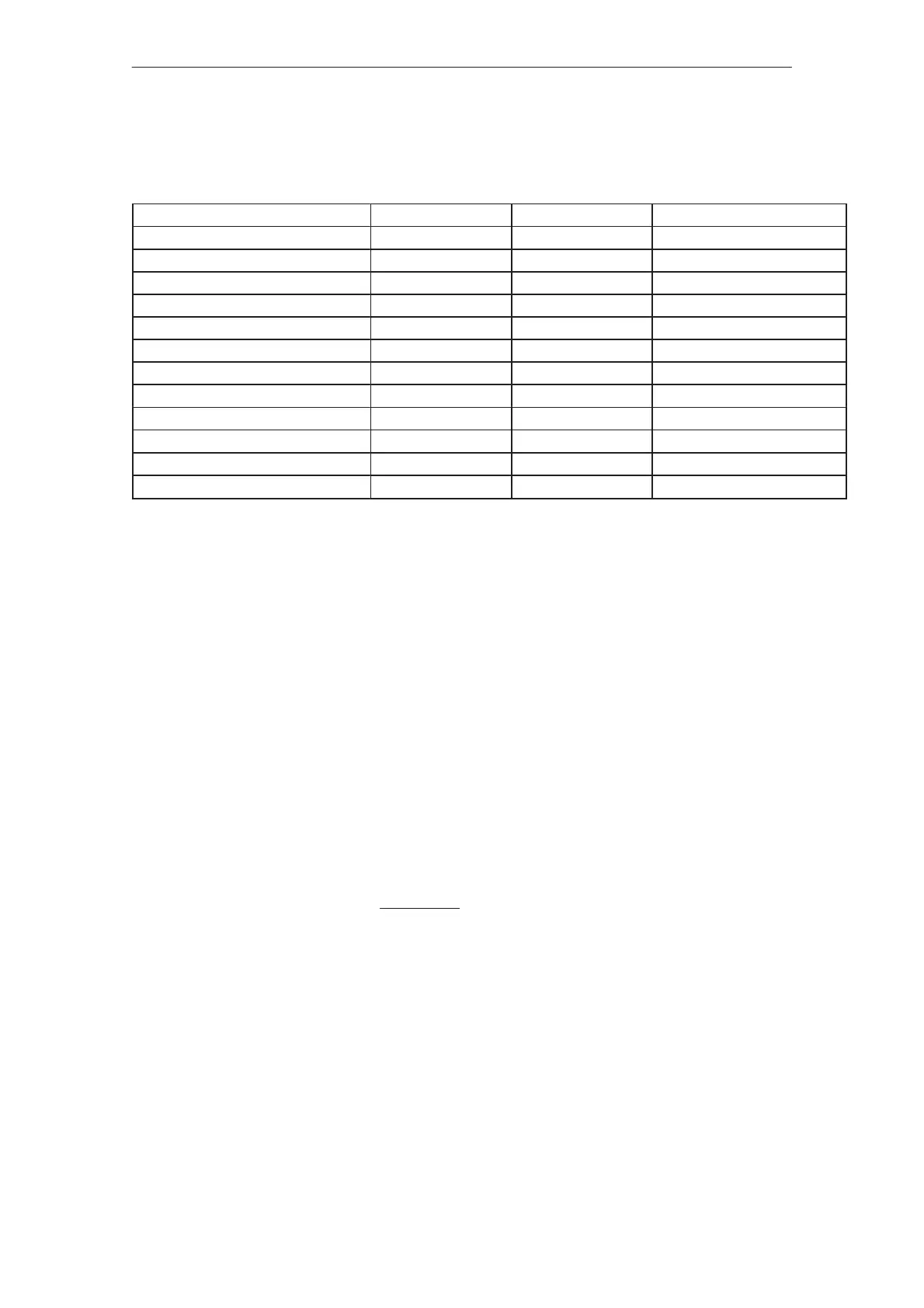

Function BKZ axis 1 BKZ axis 2 Value range

Smoothing, speed controller C231 C235 0 ... 100nF

Smoothing n

set

C232 C236 0 ... 2.2 mF

Smoothing n

act

C233 C237 0 ... 100nF

Smoothing n

set

C234 C238 0 ... 100nF

Timer ”speed controller at its endstop” C239 C240 0 ... 2.2 mF

Tachometer adaptation 539R, 540R, 541R R536, R537. R538 0 ... 1 kW, 0.1%, 25ppm/k

Clock frequency PBM R542 R542 62 kW ... 1

Adaptation range R543 R544 0 ... 1 kW

Speed setpoint adaptation R545 R546 0 ... 1 kW

Limiting, speed controller I component R547 R550 100 kW ... 2 MW

Electronic weight equalization, pos./neg. R548/R549 R551/R552 20 kW ... 1

Response threshold I

2

t monitoring

R553 R554 0 ... 1 kW

Axial metal film resistors, type of construction 0204 (RM 7.62 mm) and radial

MKT capacitors (RM 5.08 mm) must be located at the positions provided. When

adapting the tachometer, it should be observed that the resistors have a relative

accuracy of 0.1% to one another and a Tk of < 25 ppm/k.

The board could be damaged if the incorrect material is used

Only suitably qualified personnel may carry–out soldering work on the board

(maintaining the ESD Guidelines).

Dimensioning the setting elements (standard interface)

a) Smoothing functions

Speed controller:T=C231(C235)78 kW

n

set

: T=C232(C236)10 kW

n

act

: T=C233(C236)10 kW (dependent on the tachometer

potentiometer setting)

I

set

: T=C234(C238)5 kW

b) timer, ”speed controller at its endstop”

The monitoring time is 230 ms as standard, and can be increased, when requi-

red, by mounting C239 (C240). The following simple relationship is valid:

C239 (C240)

mF

T

Zst

=

)

(

+1.15

200 ms

Note

Important

Feed modules (VS)

3.1 Settings elements with standard interface 04.97

Loading...

Loading...