Siemens Energy & Automation

Machine Industry Business

6 / 10 / 96 A-3 de

Interface Drawing for ;

Date

Revision

Drawn by

611-A SERVO, STANDARD VERSION

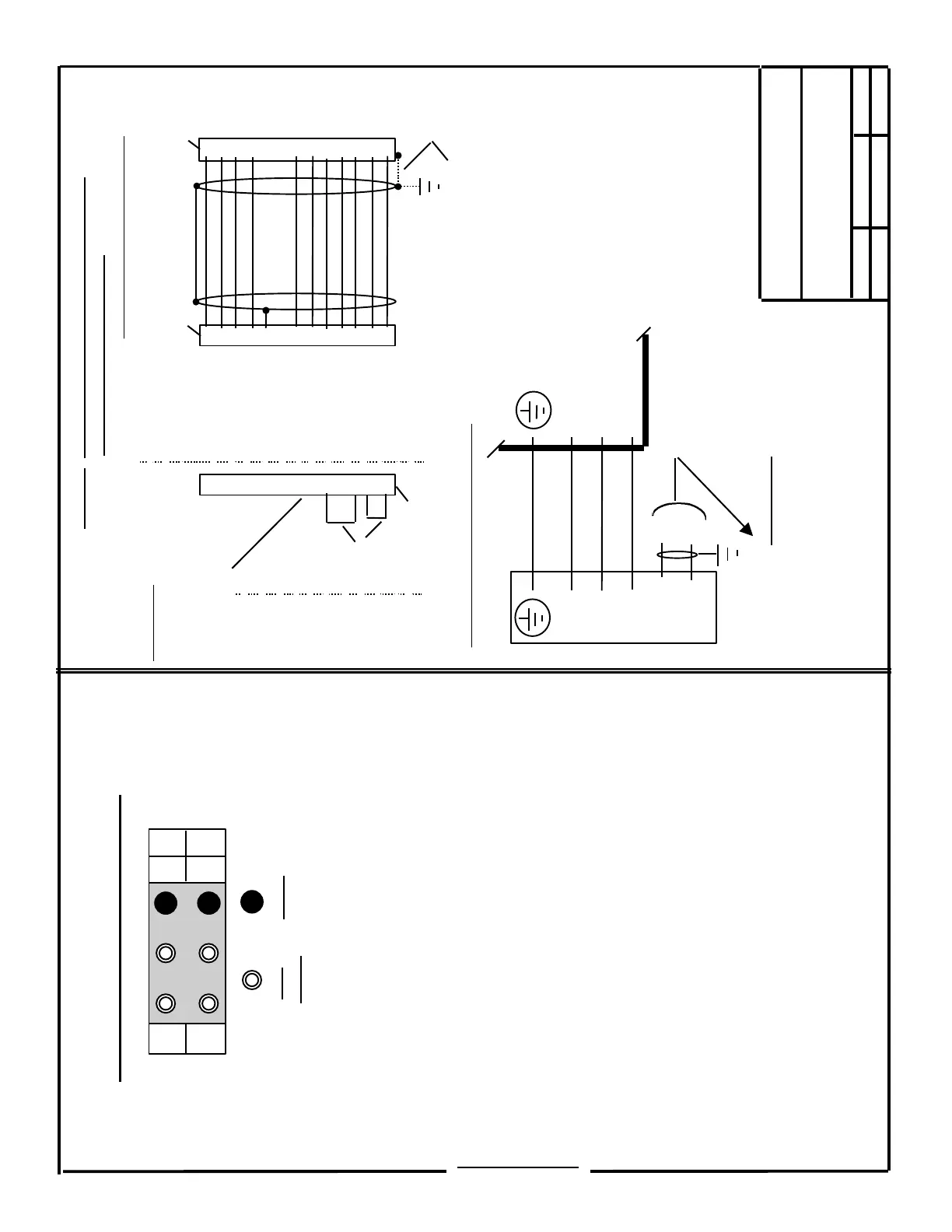

Wiring of Motor to Drive F/B Cable

Tacho, Rotor Position & Thermistor

( suggested Wire Size AWG 22 or 24 )

11

12

7

6

8

4

3

1

2

5

9

10

8

15

7

14

1

9

4

6

13

5

2

11

12

6FC9348-7AT

( Drive End )

NOTE: Motor to Drive connections

must be exactly as shown !

Connections for Optional Brake:

[24 VDC + / - 10%; Current range 0.4 to 3.25 Amps.,

dependent on Motor / Brake size].

If not used, all three (3) wires should be connected

to ground.

611-A AC SERVO

Feed Module

1 ( U )

2 ( V )

6 ( W )

5 ( BR2 )

4 ( BR )

U2

V2

W2

Wiring of Motor to Drive Power Cable

( Wire size dependent on Motor Type )

Tacho R

Tacho S

Tacho T

Tacho M

P15(RPG)

RPD R

RPD S

RPD T

M(Grnd.)

PTC

PTC

Page 2 / 3

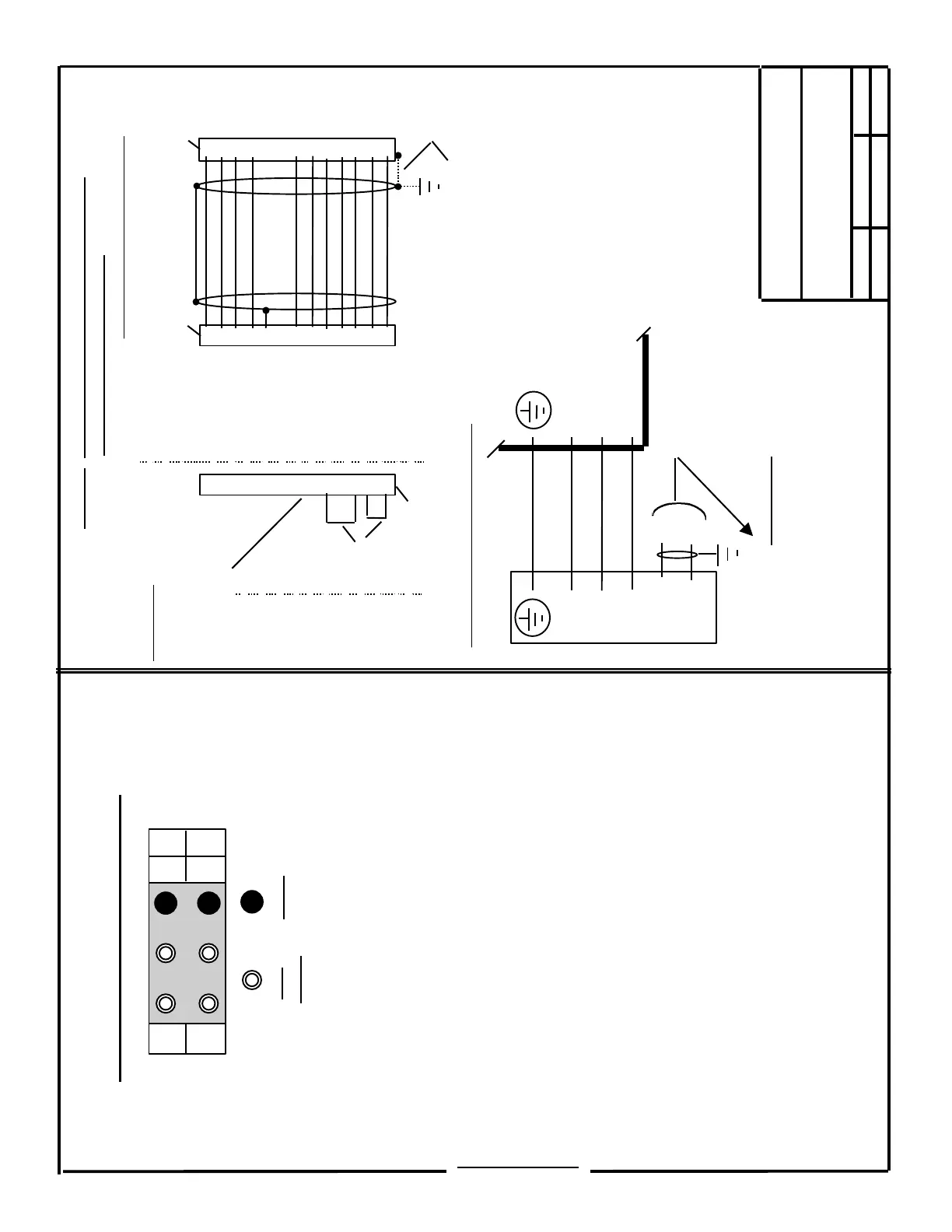

Test Points and Fault LED’s

W

M

T M

X A

Test

Points

LED’s

W - Test Point = Actual Motor Current

( 10V = I-max as set in S2-DIP; 2, 3, 4 & 5 )

M - Test Point = Common reference for

all Test Points

T - Test Point = Current Command

X - Test Point = Actual Motor Speed

( 40.0 V Tacho: 10 V = Rated Speed )

( 16.5 V Tacho: 11 V = Rated Speed )

M - LED = Motor Fault;

- Motor to Drive Cable

- Tachometer

- Rotor Position Detector

A - LED = Axis(Drive) Fault

- Speed Controller at Limit ( > 200ms )

- Drive Heat Sink Overtemperature ( > 90

o

C)

- Motor Overtemperature ( > 155

o

C + / - 5

o

C)

- I

2

T Monitoring Activated ( I-rms > 1.1 x I-rated )

6FX2003-0CE12

( Motor End )

( - )

( + )

For correct Grounding, the Shield should

be connected( on the Drive end) to either the

Connector Shell, or the 5mm screw hole

on the top of the module.

Jumpers

6FX2003 - 1CF12

- - - - - - - - - - - - - -

Dummy Plug

If the Motor F/B Cable is

disconnected the Module

will fault. If this plug is

installed (at the motor end)

the fault will not occur.

- - - - - - - - - - - - - -

11

12

7

6

8

4

3

1

2

5

9

10

SECTION F

Loading...

Loading...