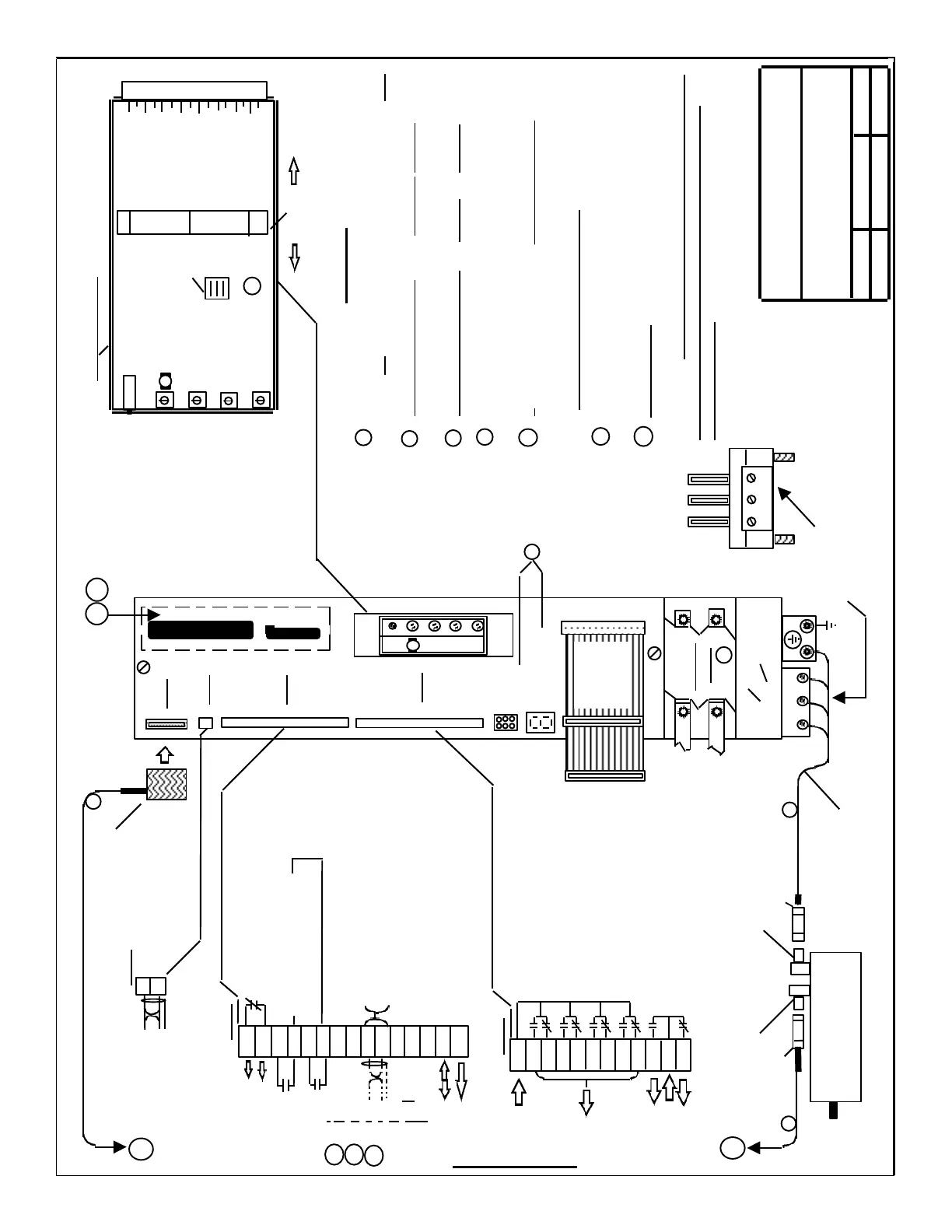

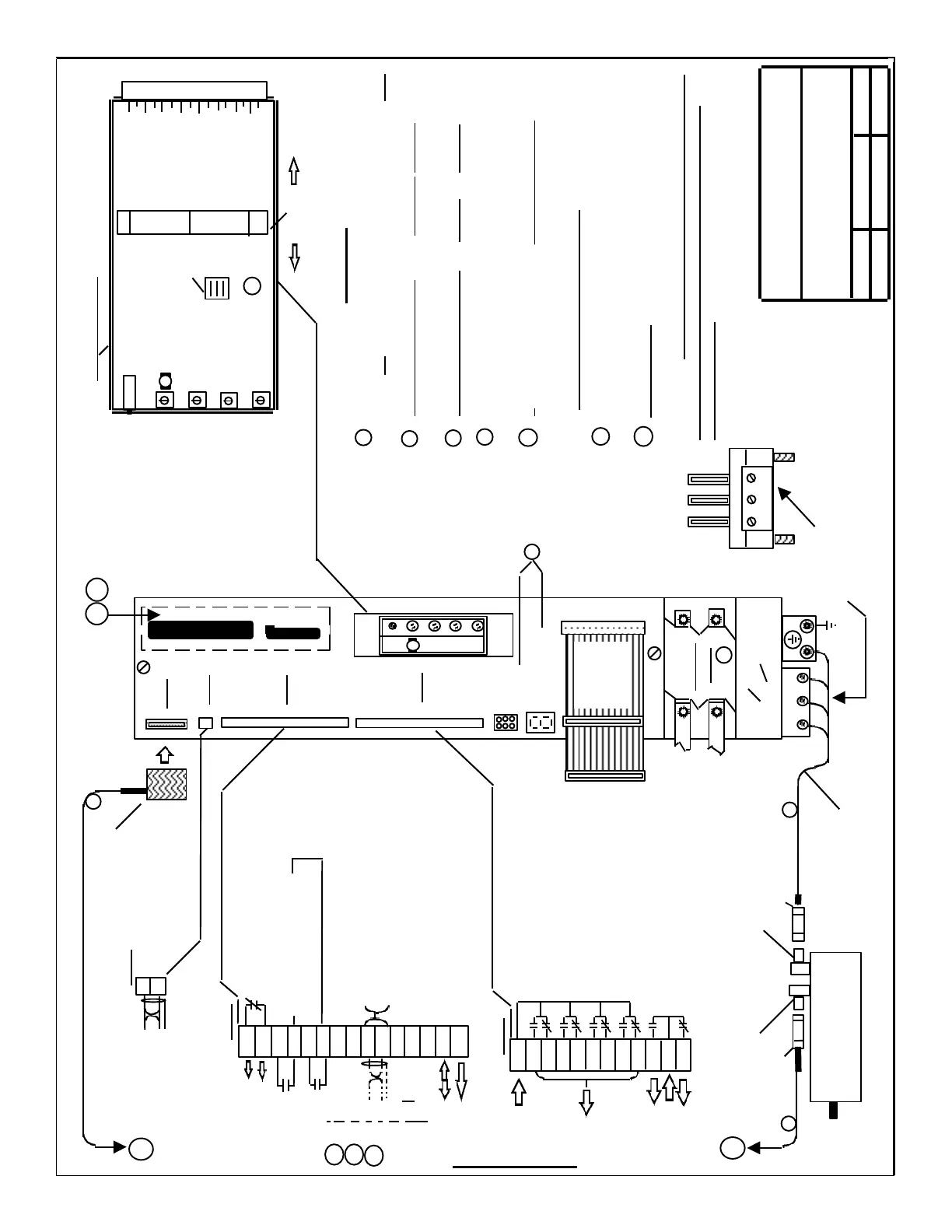

1 External, installer provided connections , are shown

on the left side of the connectors and internal on the right.

2 Solid line connections are the minimum required for

axis operation.

3 Broken line connections and Arrows are optional.

4 For additional details on Motor to Drive connections,

Test Points and the Status / Fault LED display, see Page 2 / 2.

5 If Drive is equiped with the “ Main Spindle Option “

( PCB P/N 6SN1114 - 0AA02 - 0AA0 ) the connections

and adjustments will be found on the seperate drawing ;

“ 611-A Servo Main Spindle Option “.

6 For connection details, see Drawing ; “ General Wiring

for Power, Grounding and Module Interconnection “.

W2 V2 U2

X311

X321

X331

X341

DC Link

Cover

Kp

TN

AD

Drift

T

6SN1118-0AA11-0AA1

(PCB) (Pwr. Sect.)

6SN1123-1AA . .- 0 . . 0

Primary Velocity

Command Input

56

14

+ / - 10 VDC

(Twisted &

Shielded Pair)

X321

AS1

AS2

663

9

65

9

22

23

20

24

96

44

6

258

16

- - - - -

- - - -| |- - - -

- - - -| |- - - -

- -| |- - -

- - - - - -

- - - -| |- - - -

X331

Status of the “Drive Signals”

to the Output Transistors

Pulse Enable

FR+ ( P24 for Enables )

Controller Enable

Internal Speed Command 1

Internal Speed Command 2

Secondary Velocity

Command Input

External Control of Current Limit

- 15 VDC / 10ma

Integrator Inhibit ( Velocity Loop )

Master / Slave ( Torque Command )

Iact - Actual Motor Current Output

X341

289

288

290

291

293

294

296

297

299

672

673

674

Common Input for Contacts

Speed Controller at Limit

I

2

T Activated

Motor Overtemperature

Tachometer / Rotor Position

Detector

Ready / Fault (As received = “Ready”-

Remove R33 on Parameter PCB= “Fault”)

U2 V2 W2

1FT5... AC

Servo Motor

A

A

Alternate Connector Styles ,

(Depending on Module

Current Rating )

T

Tn

Kp

S1

Tacho

Jumpers

(use only if

required)

Parameter Board - 6SN1114-0AA01-0AA0

Low Speed

Adaption

(Adaption not active

unless R34 installed )

Tachometer ( R11 )

Proportional

Gain

Integral

Gain

Drift / Balance ( R20)

( R25 )

( R35 )

AD ( R36 )

x

3

0

4

1

2

3

4

5

6

7

8

9

10

Direction

Current

Limt

Current

Loop Gain

Torque Mode

OFF / ON

S2

6FC9348-7AT

Cable

6FX2002-2CB31-1 . . 0

Cable 6FX2002-5 . A . .-1 . . 0

Siemens Energy & Automation

Machine Industry Business

6 / 3 / 97 A - 3 de

Interface Drawing for :

Date

Revision

Drawn by

PAGE 1 / 3

(12 Pins) (6 Pins)

Ribbon

Cable

BUS

Status / Fault

LED Display

Test

Points

4

4

4

4

5

NOTES

6

611-A SERVO, COMFORT VERSION

1

2

3

7 Special Note: If the Servo Module contains a “Main

Spindle Option”(PCB P/N 6SN1114- 0AA02- 0AA0 ),

components R4, R5 & C4(if installed) MUST BE REMOVED

from the Parameter Board 6SN1114 - 0AA01- 0AA0 prior

to applying power !

7

7

SECTION H

6FX2003-0CE12

6FC9348-7D. . . or

6FX2003-0C. . .

(6SY9433)

(6SY9902)

(6SY9901)

6SY9904

Loading...

Loading...