4

02.98

1-63

Siemens AG 1998 All Rights reserved 6SN1197–0AA00 02.98 Edition

SIMODRIVE 611 (PJ)

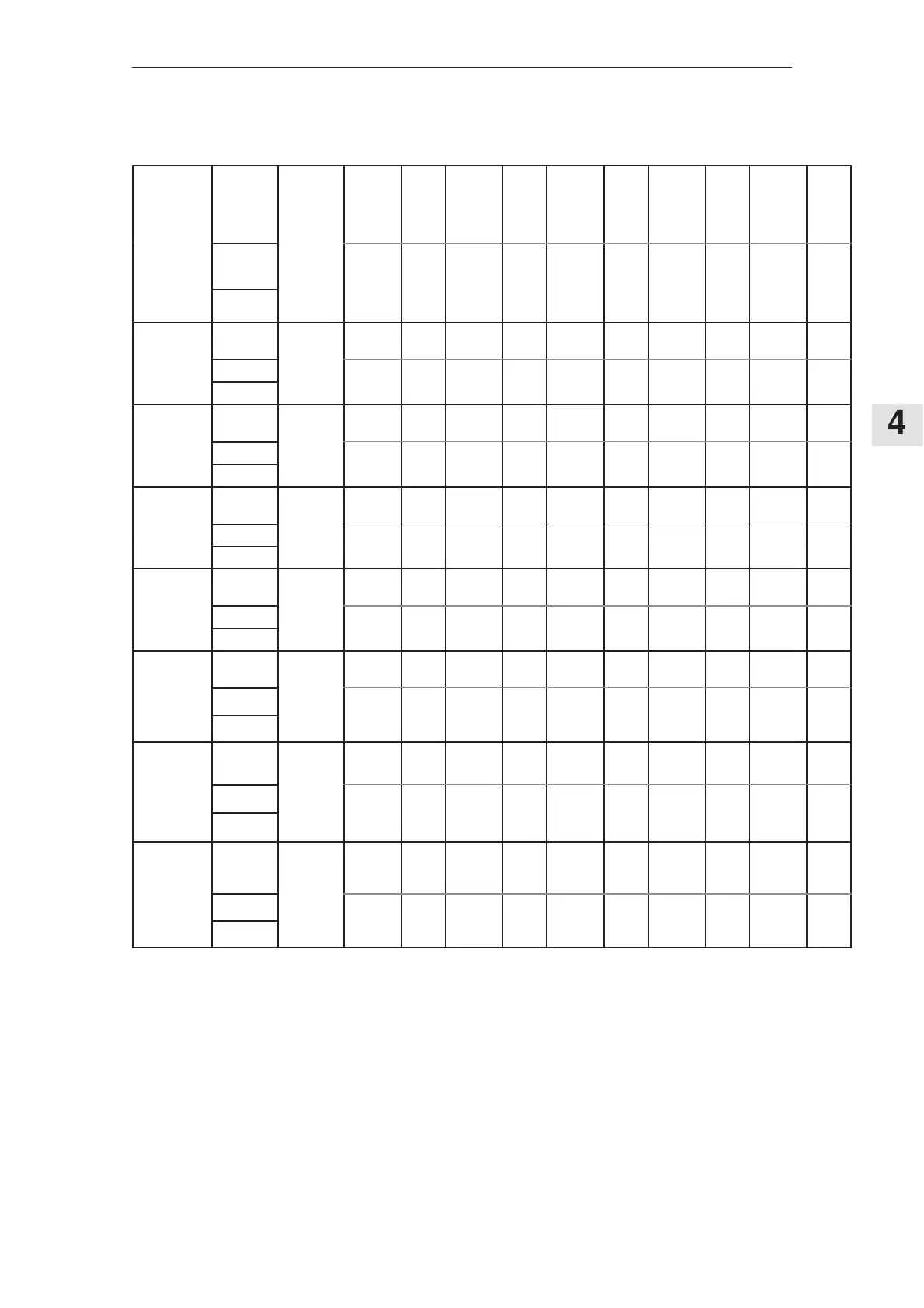

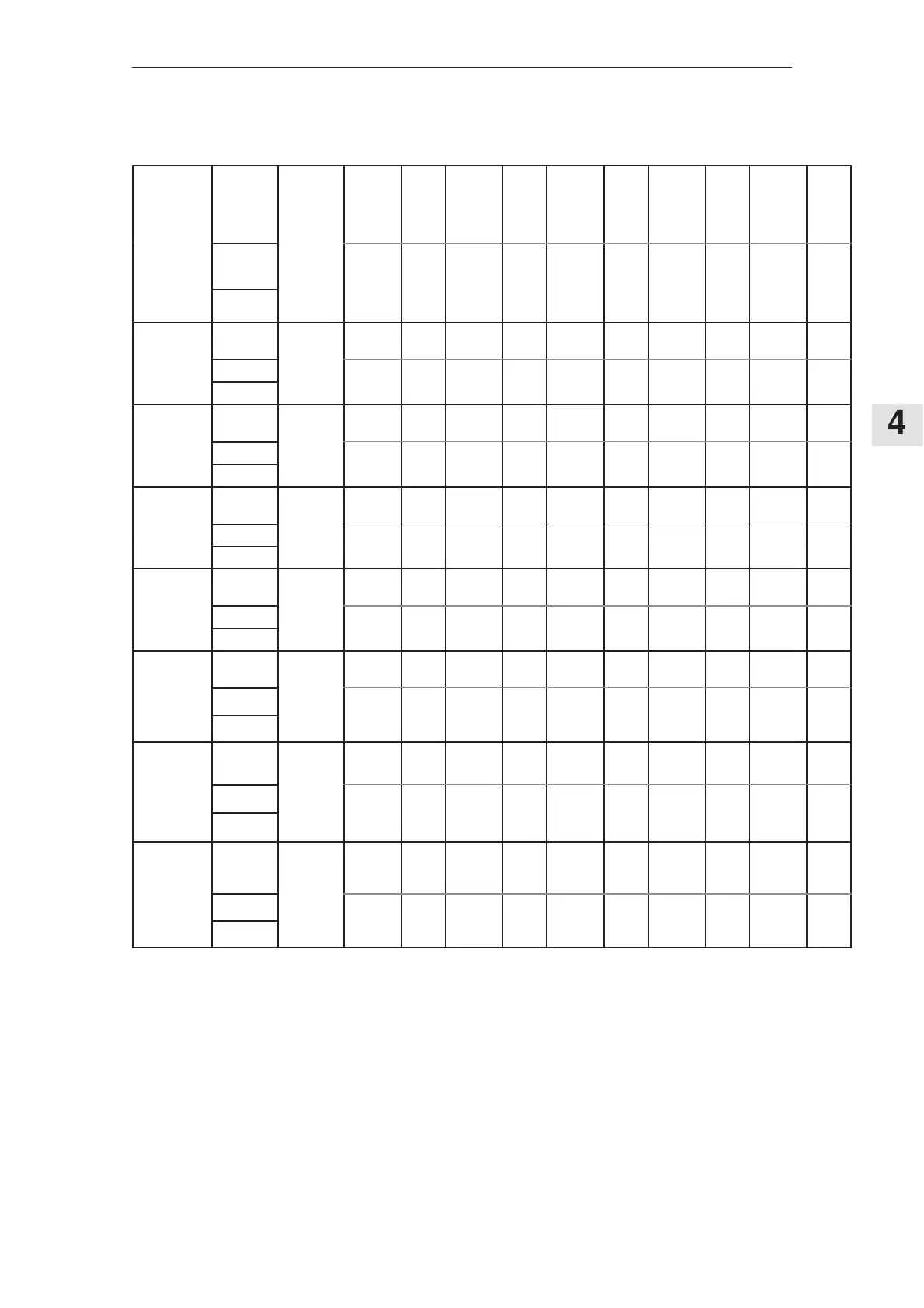

Table 4-1 Technical data, power modules internal cooling

Power

module –

Current

assign-

ment

X1

1)

[%]

FD di-

gital

I

n

/I

max

[A]

X1

1)

[%]

FD ana-

log

I

n

/I

max

[A]

X1

1)

[%]

IMM di-

gital

I

n

/I

s6

/

I

max

[A]

X1

1)

[%]

IMM

analog

I

n

/I

s6

/

I

max

[A]

X1

1)

[%]

MSD –

analog/

digital

I

n

/I

s6

/

I

max

[A]

Max.

conduc-

tor

cross–

section

2)

[mm

2

]

Cooling

type

5)

Power

module –

Current

assign-

ment

f

0

1)

[kHz]

Losses

[W]

Pv

tot.

f

0

1)

[kHz]

Losses

[W]

Pv

tot.

f

0

1)

[kHz]

Losses

[W]

Pv

tot.

f

0

1)

[kHz]

Losses

[W]

Pv

tot.

f

0

1)

[kHz]

Losses

[W]

Pv

tot.

Max.

conduc-

tor

cross–

section

2)

[mm

2

]

Max.

width

[mm]

Power

module –

Current

assign-

ment

f

0

1)

[kHz]

Losses

[W]

Pv

tot.

f

0

1)

[kHz]

Losses

[W]

Pv

tot.

f

0

1)

[kHz]

Losses

[W]

Pv

tot.

f

0

1)

[kHz]

Losses

[W]

Pv

tot.

f

0

1)

[kHz]

Losses

[W]

Pv

tot.

Max.

conduc-

tor

cross–

section

2)

[mm

2

]

Weight

[kg]

Power mo-

dule

F

16/10

30/40/

51

55

30/40/

51

55

28/37/

47

55 40/80 50 28/56 50

dule

Int.80 A

100

16/10

320 32 320 32 320 40 300 33 300 4

Int.80 A

9.5

320 3.2 320 3.2 320 4.0 300 3.3 300 4

Power mo-

duleint108

F

50

45/60/

76

55

45/60/

76

55

42/56/

70

55

– – –

dule, int.108

A

150

50

460 32 460 32 460 40

– – –

A

13

460 3.2 460 3.2 460 4.0

Power mo-

duleint160

F

50

60/80/

102

50

60/80/

102

50

55/73/

94

50 80/160 55 56/112 55

dule, int.160

A

150

50

685 32 685 32 685 40 655 33 645 4

A

13

685 3.2 685 3.2 685 4.0 655 3.3 645 4

Power mo-

duleint200

F

95 or

85/110/

127

55

85/110/

127

55

79/102/

117

55 100/200 55 70/140 55

dule, int.200

A

300

95 or

2 x 35

850 32 850 32 850 40 740 33 730 4

A

26

850 3.2 850 3.2 850 4.0 740 3.3 730 4

Power mo-

duleint

F

95or

85/110/

127

55

85/110/

127

55

79/102/

117

55 100/200 55 70/140 55

dule, int.

200

A pipe

connection

300

95 or

2 x 35

–/750/

100

32

–/750/

100

32

–/750/

100

40

–/650/

90

33

–/640/

90

4

connection

26

100

4)

3.2

100

4)

3.2

100

4)

4.0

90

4)

3.3

90

4)

4

Power mo-

dule, int.300

A

3)

F

95or

120/

150/193

50

120/

150/193

50

110/

138/177

50

– – – –

A

)

pipe con-

nectionor

300

95 or

2 x 35

1290/

1100/

32

1290/

1100/

32

1290/

1100/

40

– – – –

nection or

radial fan

26

1100/

190

4)

3.2

1100/

190

4)

3.2

1100/

190

4)

4.0

Power mo-

dule,

int.400

A

3)

F

150 or

200/

250/257

50

200/

250/257

50

183/

229/236

50

– –

140/

210

50

pipe con-

nection or

300

2 x 50

2170/

1845/

32

2170/

1845/

32

2170/

1845/

40

– –

1660/

1910/

4

nection or

radial fan

28

1845/

325

4)

3.2

1845/

325

4)

3.2

1845/

325

4)

4.0

1910/

250

4)

1) X1=current reduction factor, current reduction from the inverter clock frequency f

0

of the power transistors

(refer to Fig.4-2)

2) The 1st number is valid for cable lugs, the 2nd number is valid for finely–stranded conductors without conn. sleeves.

3) If pipe cooling is not used, only Pv

tot.

should be taken into account.

4) Pv

total

/Pv

pipe

/Pv

internal

5) F = force–ventilated, S = self–ventilated

4.1 Technical data

Loading...

Loading...