4

02.98

1-64

Siemens AG 1998 All Rights reserved 6SN1197–0AA00 02.98 Edition

SIMODRIVE 611 (PJ)

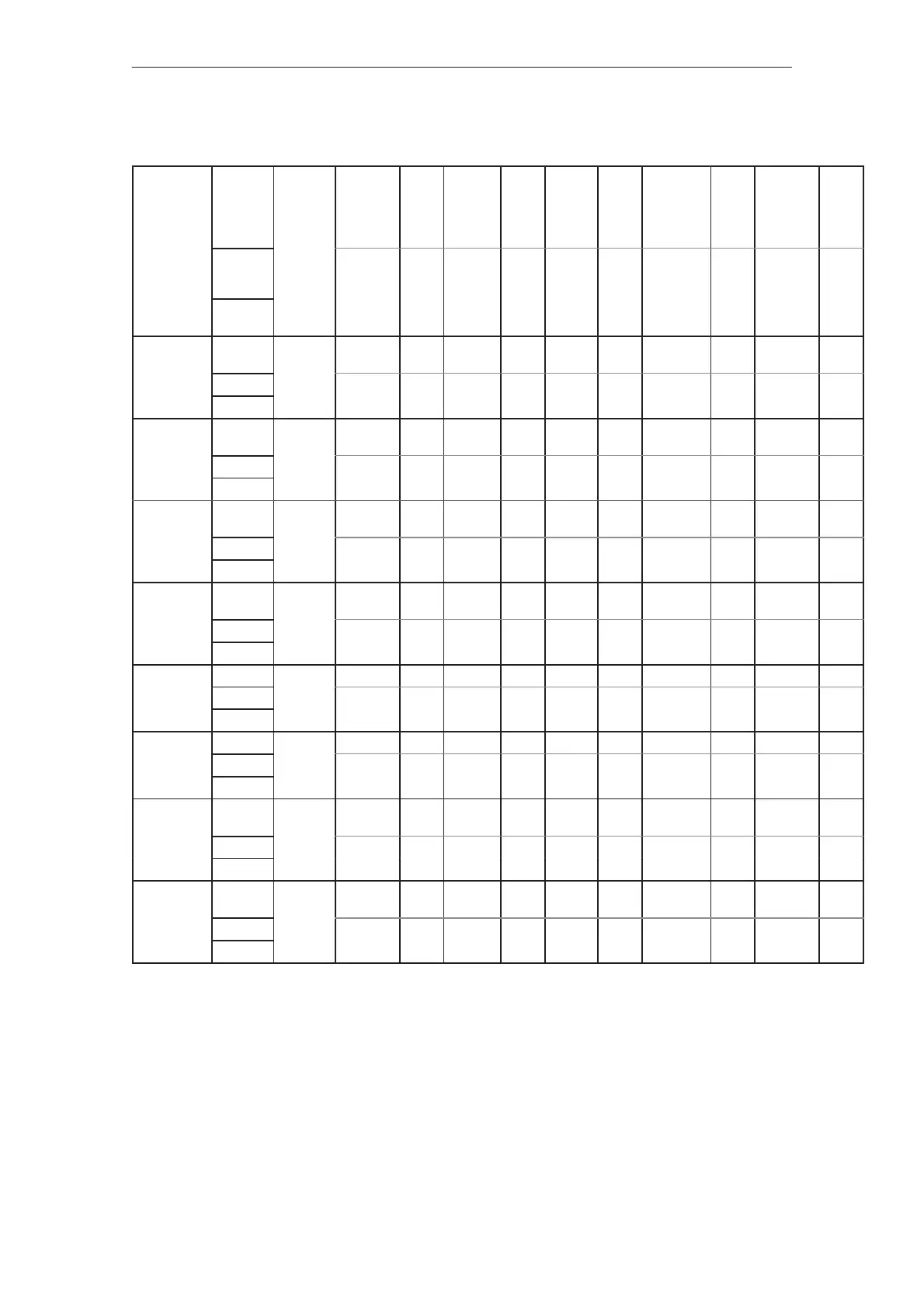

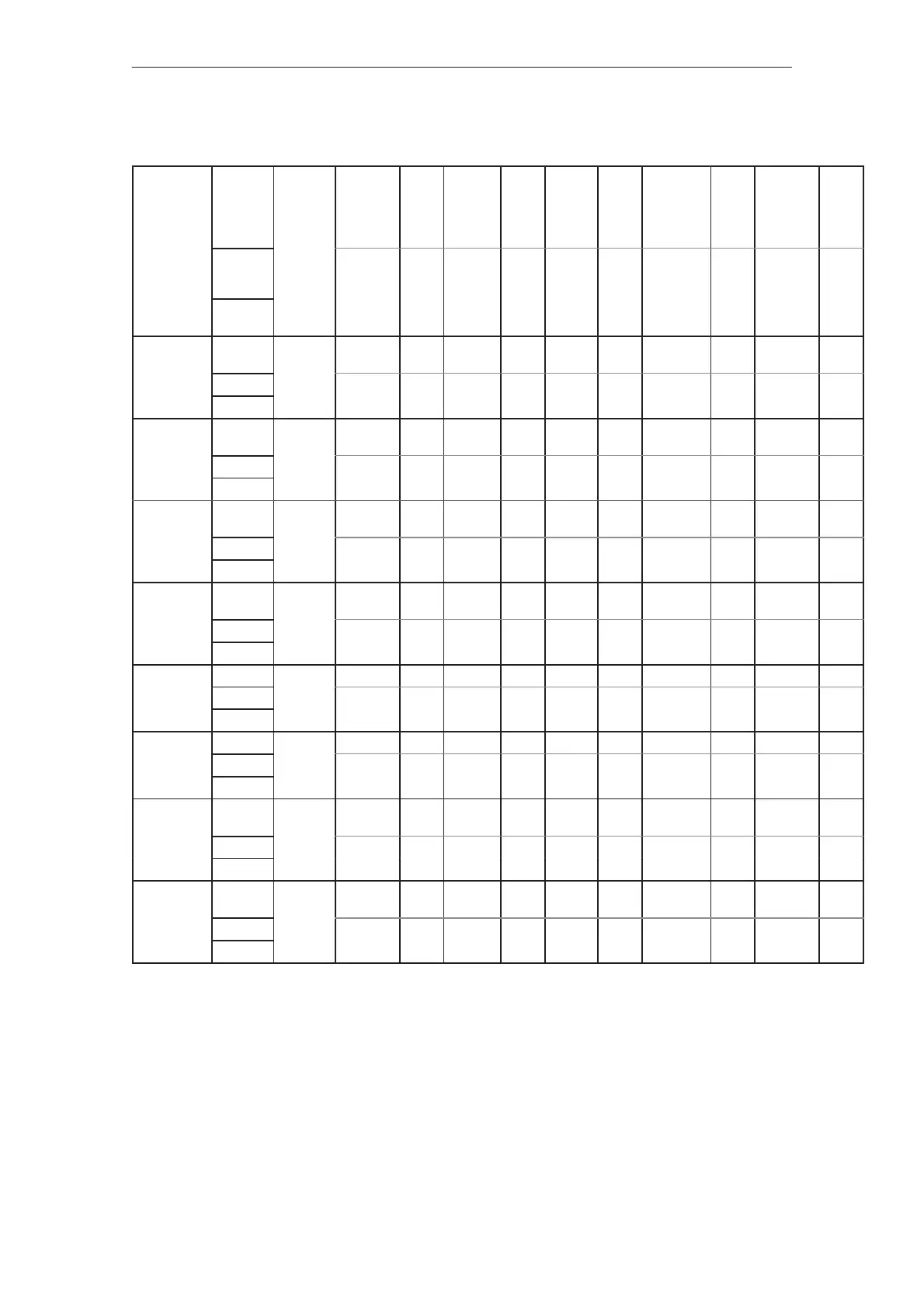

Table 4-2 Technical data, power modules external cooling

Power

module –

current

assign-

ment

Cooling

type

5)

Max.

cross–

section

2)

[mm

2

]

MSD –

analog/

digital

I

n

/I

s6

/

I

max

[A]

X1

1)

[%]

IMM

analog

I

n

/I

s6

/

I

max

[A]

X1

1)

[%]

IMM

digital

I

n

/I

s6

/

I

max

[A]

X1

1)

[%]

FD –

analog

I

n

/I

max

[A]

X1

1)

[%]

FD –

digital

I

n

/I

max

[A]

X1

1)

[%]

Max.

width

[mm]

Losses

[W]

Pv

t

/

f

0

1)

[kHz]

Losses

[W]

Pv

t

/

f

0

1)

[kHz]

Los-

ses

[W]

f

0

1)

[kHz]

Losses

[W]

Pv

t

/

f

0

1)

[kHz]

Losses

[W]

Pv

t

/

f

0

1)

[kHz]

Weight

[kg]

Pv

ext

/

Pv

int

[kHz] Pv

ext

/

Pv

int

[kHz]

Pv

ext

/

Pv

int

[kHz] Pv

ext

/

Pv

int

[kHz] Pv

ext

/

Pv

int

[kHz]

Power mo-

F

6/4

– – 3/3/3 50

2.8/2.8/

2.8

50 4/8 55 3/6 55

Power mo

dule, ext. 8

50

6/4

– – 18/12 32 18/12 40 21/14 33 21/14 4

6.5

– – 18/12 3.2 18/12 4.0 21/14 3.3 21/14 4

Power mo-

F

6/4

– – 5/5/8 50

4.6/4.6/

7.3

50 7.5/15 55 5/10 55

Power mo

dule, ext. 15

50

6/4

– – 24/16 32 24/16 40 27/18 33 31/19 4

6.5

– – 24/ 16 3.2 24/ 16 4.0 27/18 3.3 31/19 4

Power mo-

dule

F

6/4

– – 8/10/16 55

7.4/9.3/

14.8

55 12.5/25 55 9/18 55

dule,

ext.25A

50

6/4

– – 45/29 32 45/29 40 55/35 33 55/35 4

ext.25A

6.5

– – 45/29 3.2 45/29 4.0 55/35 3.3 55/35 4

Power mo-

F

6/4

24/32/32 40

24/32/

32

40

22/29/

29

40 25/50 40 18/36 40

Power mo

dule, ext.50

50

6/4

171/89 32 171/89 32 171/89 40 118/62 33 125/65 4

7.5

171/89 3.2 171/89 3.2 171/89 4.0 118/62 3.3 125/65 4

Power mo-

F – – – – – – 24/8 55 23/6 55

Power mo

dule, ext.

28

50 6/4

– – – – – – 43/27 33 43/27 4

28

7

– – – – – – 43/27 3.3 43/27 4

Power mo-

F – – – – – – 27.5/15 55 25/10 55

Power mo

dule, ext.

215A

50 6/4

– – – – – – 64/40 33 62/38 4

215 A

7

– – – – – – 64/40 3.3 62/38 4

Power mo-

dule

F

6/4

– – – – – –

212.5/2

5

55 29/18 55

dule,

ext.225A

50

6/4

– – – – – – 107/67 33 111/69 4

ext.225A

7

– – – – – – 107/67 3.3 111/69 4

Power mo-

dule

F

6/4

– – – –

28/37/

47

55 225/50 40 218/36 40

dule,

ext.250

A

100

6/4

– – – – 28/32 40 240/124 33 250/130 4

ext.250 A

13.5

– – – – 28/32 4.0 240/124 3.3 250/130 4

_________

1) X1=current reduction factor, current reduction from the inverter clock frequency f

0

of the power transistors

(refer to Fig.4-2)

2) The 1st number is valid for cable lugs, the 2nd number is valid for finely–stranded conductors without conn. sleeves.

3) If pipe cooling is not used, only Pv

tot.

should be taken into account.

4) Pv

total

/Pv

pipe

/Pv

internal

5) F = force–ventilated, S = self–ventilated

4.1 Technical data

Loading...

Loading...